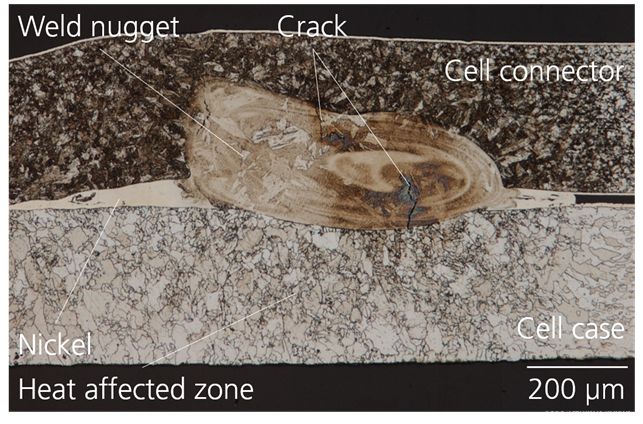

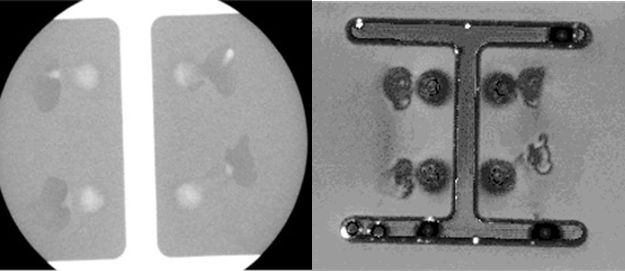

Battery storage systems for the reliable and efficient intermediate storage of solar and wind power as well as for electromobility are composed of individual battery cells. The interconnection of single battery cells to form battery modules or battery packs is decisive for the reliability of a battery storage system. At Fraunhofer ISE, we are developing and analyzing suitable processes, such as resistance welding and laser bonding, to electrically contact battery cells via battery cell connectors.

Based on our experience in connection technology, we characterize the electrical and mechanical properties of joints as well as their reliability and long-term stability. The practical process development is supported by the modeling of the interconnection processes with the finite element method (FEM) and the dimensioning of the cell connectors. This also includes the simulation of heat generation during operation and the influence of contact resistances on the cell behavior in the interconnection as well as the aging processes.

Technical requirements for interconnection technology in electrical battery interconnection are:

- Joints with contacts that are as identical as possible

- Smallest possible electrical contact resistances

- Lowest possible heat effect during the joining process

- Flexible interconnection process for a wide range of surface conditions and materials

- Long-term stability even under extreme operating conditions (temperature, humidity, vibrations, etc.)