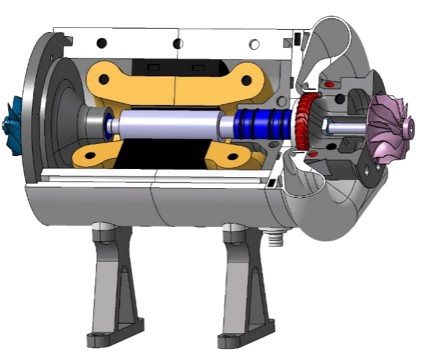

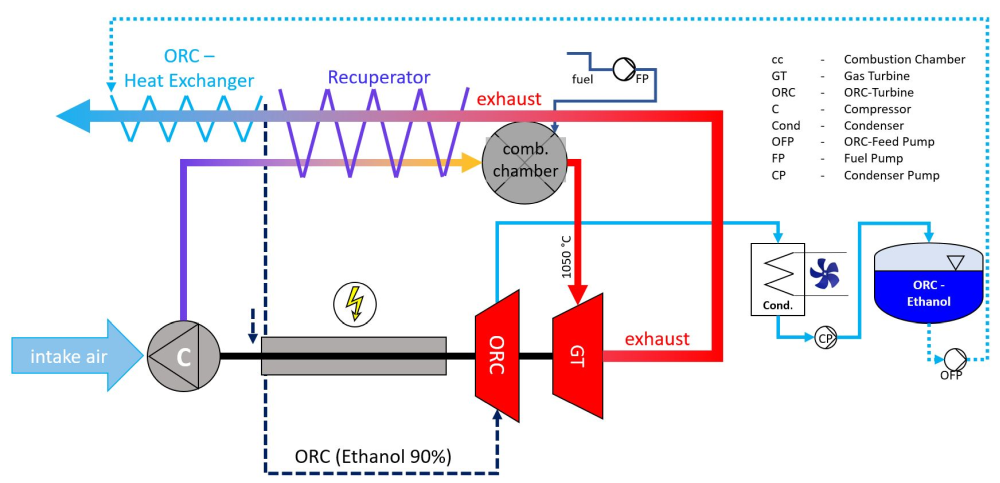

This project aims to develop and demonstrate an advantageous and innovative alternative to combined heat and power (CHP) plants: the combustion of gases in a micro gas turbine (mGT) and the use of the high exhaust gas temperatures in a following organic Rankine cycle (ORC). The efficiency can match that of a CHP and offers decisive advantages of the mGT over conventional combustion. These are primarily very low-emission combustion (especially NOx) and high fuel flexibility. A central component and, at the same time, a challenge in such a combination are high-temperature -resistant ceramic heat exchangers and other components that are being developed in the project. Two system variants are being built and tested in the project. A new feature is the combination of mGT and ORC on a common drive shaft to form a micro hybrid turbine (“MiHyT”) with a ceramic coaxial heat exchanger. Various manufacturing options and designs are being tested and compared in the development of the ceramic heat exchangers and turbine components. As an alternative to the use of gas combustion, the economic feasibility of “solar firing” of the mGT using solar tower technology is being investigated. Further applications of the technologies developed are being evaluated in the project.

In particular for larger power classes, it is also possible to decouple mGT and ORC and operate them in parallel, for which an ORC system with a turbine for utilizing temperatures up to 200-300°C based on a commercial ORC unit is being developed.