Fuel cell technology offers significant potential for the decarbonization of heavy-duty transport. A necessary prerequisite is that membrane electrode assemblies (MEAs) can be manufactured on an industrial scale in an environmentally friendly and cost-effective manner. The "DirectStack2Scale" project is developing technologies for quality control of heavy-duty MEAs based on fluorine-free hydrocarbon materials as an alternative to PFAS. Fraunhofer ISE's research focuses on developing models that describe the aging of the new materials under operating conditions and on experimentally characterizing degradation effects to validate the simulations.

Quality Control of Novel Hydrocarbon-based Membrane Electrode Assemblies for Fuel Cells

DirectStack2Scale

Initial Situation

Fuel cell drives are considered a promising emission-free drive system for heavy-duty vehicles because they combine high payloads and ranges with short refueling times and low total cost of ownership. To unlock this potential, MEAs for heavy-duty applications must be environmentally friendly and manufactured on an industrial scale with low margin of fluctuations in product properties.

However, the MEA, the performance- and cost-determining “heart” of a fuel cell, requires polymer material as the membrane and as the ionomer within the electrodes, which typically contains PFAS compounds. Hydrocarbon-based materials are becoming increasingly important as fluorine-free and sustainable alternatives for many industrial processes that have previously relied on PFAS materials.

Objective

The "DirectStack2Scale" project aims to contribute to environmentally friendly, efficient MEAs for heavy-duty applications by investigating and evaluating errors in the production of fluorine-free hydrocarbon-based MEAs and integrating quality control measures into the process chain.

Building on the previous project, “DirectStack”, in which the method of direct coating of MEAs using conventional PFAS materials was validated for the first time with industrial partners, "DirectStack2Scale" focuses on demonstrating the production of directly coated hydrocarbon-based MEAs on a pilot scale plant using the identified quality control criteria.

Approach

In addition to consortium partners ionysis GmbH (manufacture of hydrocarbon-based MEAs), JWS GmbH (plant development for roll-to-roll processes), and HAW Kempten (in-situ and ex-situ characterization of fuel cells), Fraunhofer ISE is contributing its expertise in the field of fuel cell performance and aging modeling to this project. For reliable and sustainable operation of the MEA, degradation effects must be identified and their influence on fuel cell performance quantified.

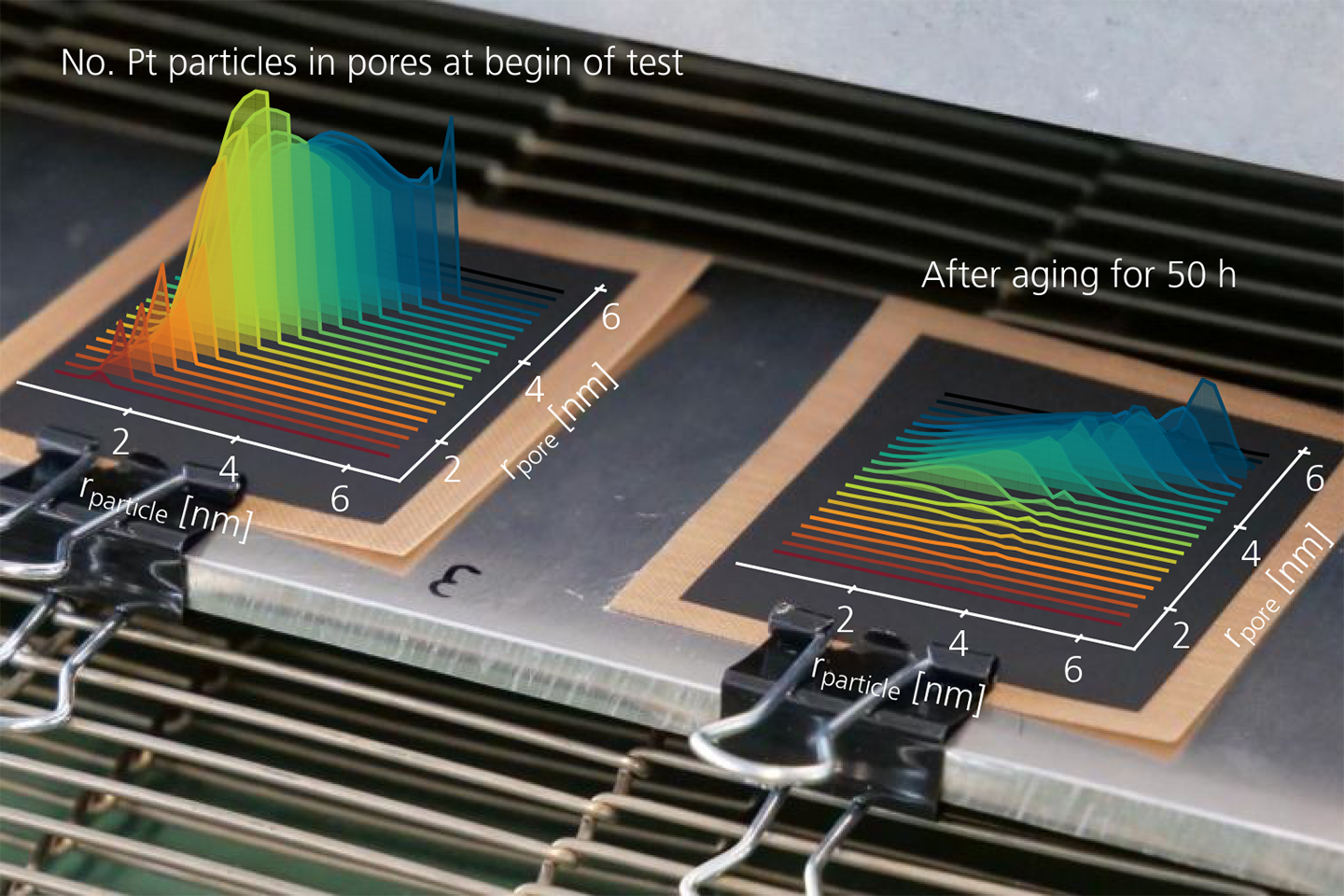

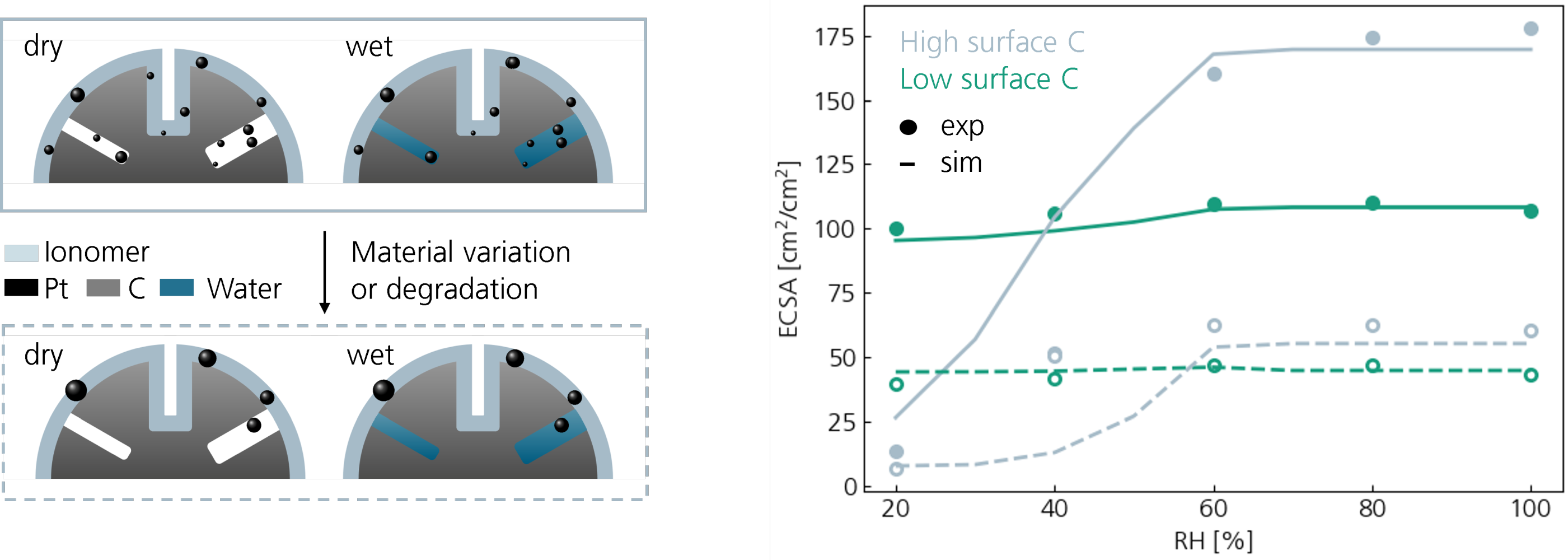

Due to the high material and cost expenditure involved, experimental aging tests are generally preferred in accelerated form. Suitable physical models can bridge the gap between measured indicators and actual fuel cell degradation in order to predict the service life of the materials as accurately as possible. The development of models for hydrocarbon-based materials at Fraunhofer ISE is supported by experimental characterization of degradation.

nicht entfernen!!

Funding

The Fraunhofer ISE subproject in the "DirectStack2Scale" project is funded by the German Federal Ministry of Transport (BMV) with a total of €357,323.00 under the “National Innovation Program for Hydrogen and Fuel Cell Technology” guideline. The grant guideline is coordinated by NOW GmbH and implemented by Projektträger Jülich (PtJ).