| Duration: | 07/2022 - 06/2024 |

| Contracting Authority/ Sponsors: | Federal Ministry for Digital and Transport |

| Project Partners: | Coatema, IFA, associated Partner: EKRA (ASYS) und Heraeus |

| Project Focus: |

TiKaBe – Ink Development for Fuel Cell Catalyst Coating

The market ramp-up of proton exchange membrane (PEM) fuel cell technology requires new concepts for manufacturing the membrane electrode assembly (MEA) with shorter cycle times and increased resource efficiency. Only in this way can the industrially required quantities be achieved at the targeted costs. To this end, suitable and rapid coating processes for large quantities must be developed and established. In the TiKaBe project (ink development for fuel cell catalyst coating), Fraunhofer ISE is developing and validating catalyst inks for highly scalable, industrial coating processes. The project is part of the HyFab project network, which is intended to create a knowledge base for the automotive and supplier industry to facilitate research into fuel cell production technologies.

Fuel cells are a key technology for the future hydrogen economy. After decades of research and development, the phase of industrialisation is now beginning. There is strong demand for fuel cell technologies, especially in heavy-duty transport. This is the case across the globe, giving rise to a substantial market volume with correspondingly high production quantities.

In terms of the MEA, the electrochemical heart of the fuel cell, this means that long-lasting membrane electrode units with low precious metal content will need to be developed. This requires highly scalable, industrial coating processes. In addition to the currently established slot-die coating, which is the preferred method for very homogeneous, continuous coatings, printing processes such as inkjet, engraving and screen printing will also be interesting in the future because they enable the production of structured layers.

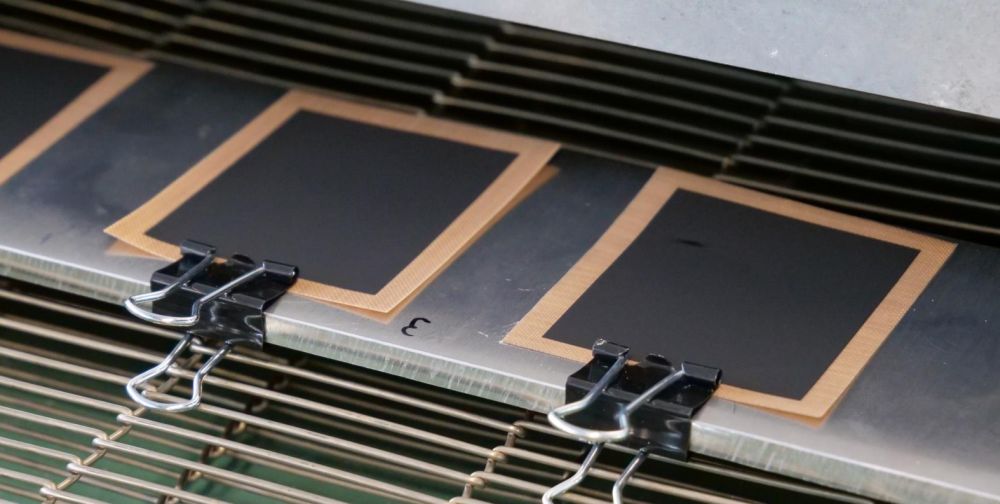

In the project, the first step will be the development and validation of catalyst inks (TRL = 6) that are suitable for the aforementioned coating processes. The developed inks will be validated through the production of catalyst layers, catalyst-coated membranes (CCMs) and MEAs in the laboratory, as well as in the subsequent characterisation of the components in fuel cell test stands. Finally, selected ink formulations will be transferred to the industrial scale.

Fraunhofer ISE has well-developed ink/paste production laboratories (equipped with gloveboxes, fume hoods, ink characterisation equipment, etc.) and extensive knowledge and experience in the formulation of catalyst inks.

The flexible CCM production and process development infrastructure is adaptable to different materials at pilot lane laboratory scale, so that the developed catalyst inks can be evaluated at CCM and MEA levels.

The aim of the project is to develop catalyst inks for different coating processes as well as for the respective drying. Furthermore, the project aims to achieve stable wetting of decal/transfer films and membranes (direct coating) and rapid drying (less than one minute).

The know-how generated in this way is intended to help German suppliers from plant engineering, material production and MEA manufacturers to take a leading position in the internationally competitive MEA production market.

The project »TiKaBe« (ink development for fuel cell catalyst coating) is funded by the German Federal Ministry of Digital Affairs and Transport within the framework of the National Innovation Programme for Hydrogen and Fuel Cell Technology with a total of 1,344,738.00 euros. The funding guideline is coordinated by NOW GmbH and implemented by Project Management Jülich (PtJ).

Links

- HyFab-BW - HyFab-Baden-Württemberg (ise.fraunhofer.de)