The cost-effective and efficient global trade of green hydrogen, stored e. g. in the form of dimethyl ether (DME), lays the foundation for the defossilization of the industry. The “EARTH2” (Efficient And Resource-saving Transport of Hydrogen using dimethyl ether) project aims to industrialize an innovative and efficient chemical process for the production of the hydrogen carrier DME. The novel process using reactive distillation, in which the thermodynamic reaction equilibrium is bypassed by coupling synthesis and distillation, reduces energy requirements, plant complexity and investment costs. Funded by the Fraunhofer Future Foundation, the process for DME production is to be brought into industrial application.

Efficient and Resource-saving Transport of Hydrogen using Dimethyl Ether

EARTH2

Initial Situation

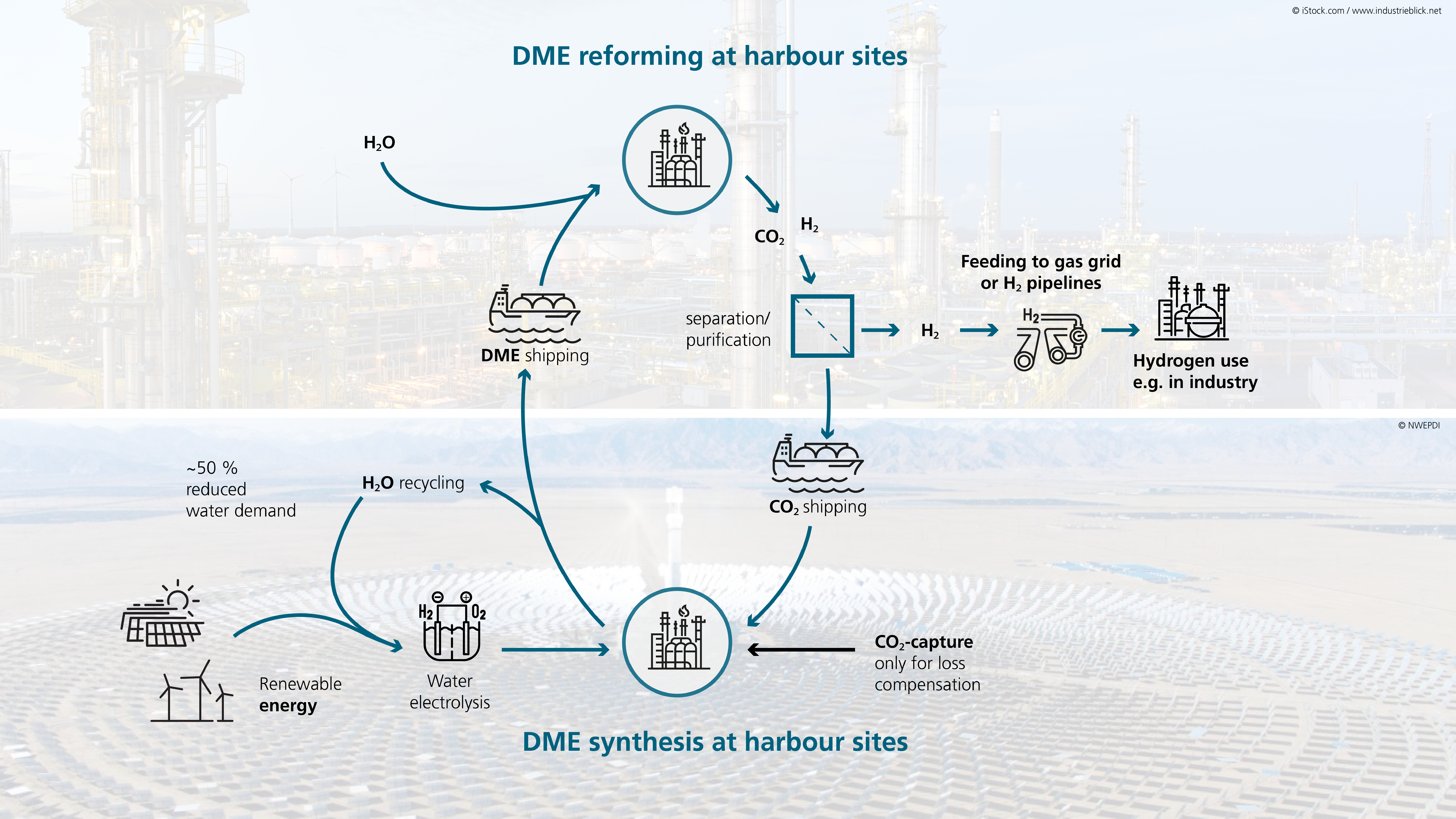

There is no alternative to hydrogen for the transition to a CO2-neutral industry in many sectors, such as steel production. However, due to Germany's limited potential for generating renewable energy, the required hydrogen can only be produced domestically to a limited extent and at relatively high costs. A successful defossilization of the German industry while at the same time ensuring economic competitiveness therefore requires a cost-efficient import of green hydrogen to Germany.

In this context, DME could serve as an excellent hydrogen carrier due to its high hydrogen storage capacity and environmental friendliness. In addition, DME production produces water as a by-product, which can be fed back into the water electrolysis process. This can reduce the demand for water in sun-rich production countries, which are often characterized by water scarcity.

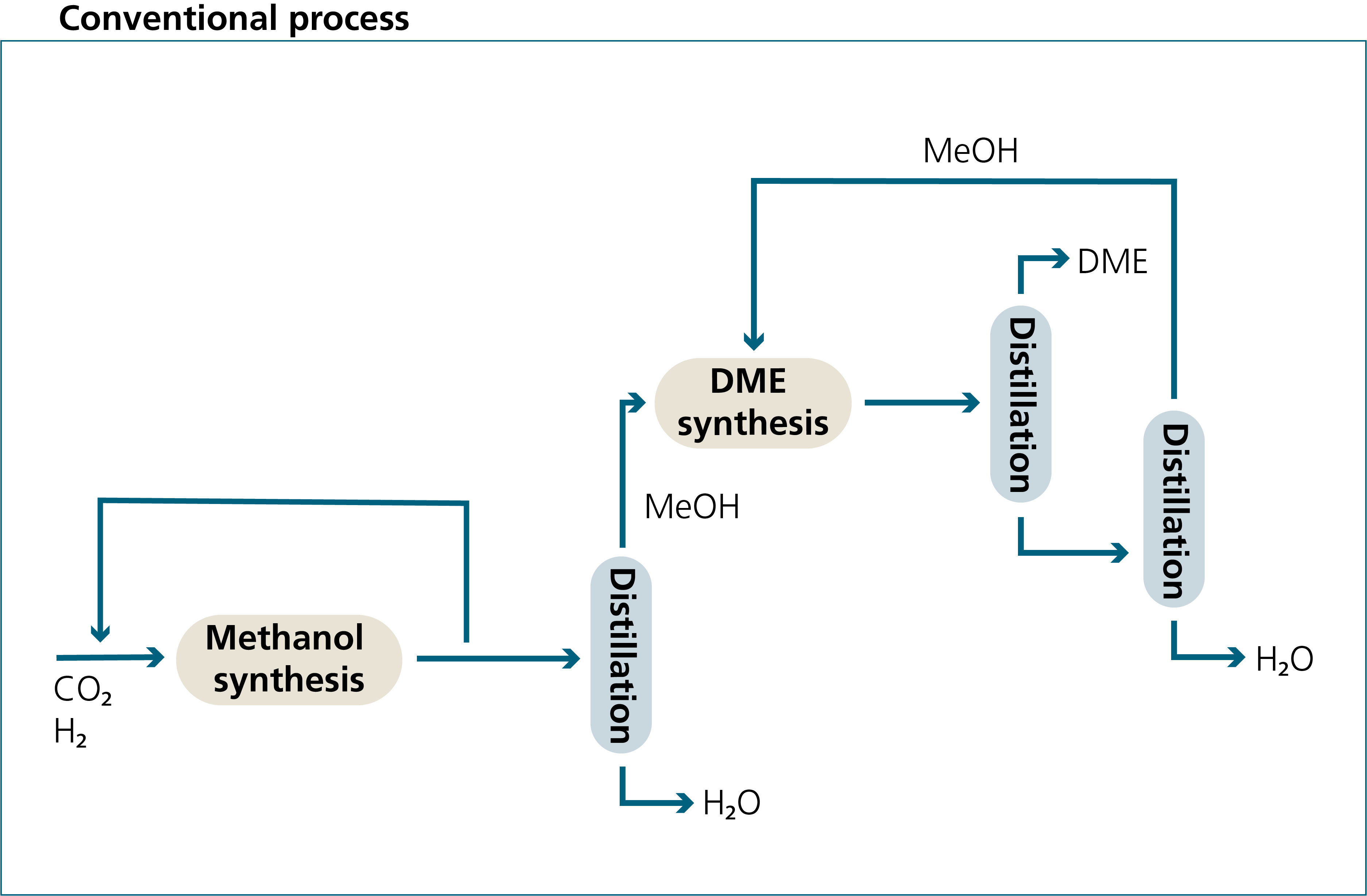

However, DME is currently produced using a complex and energy-intensive process, which reduces the overall efficiency of converting renewable energy into DME.

Objective

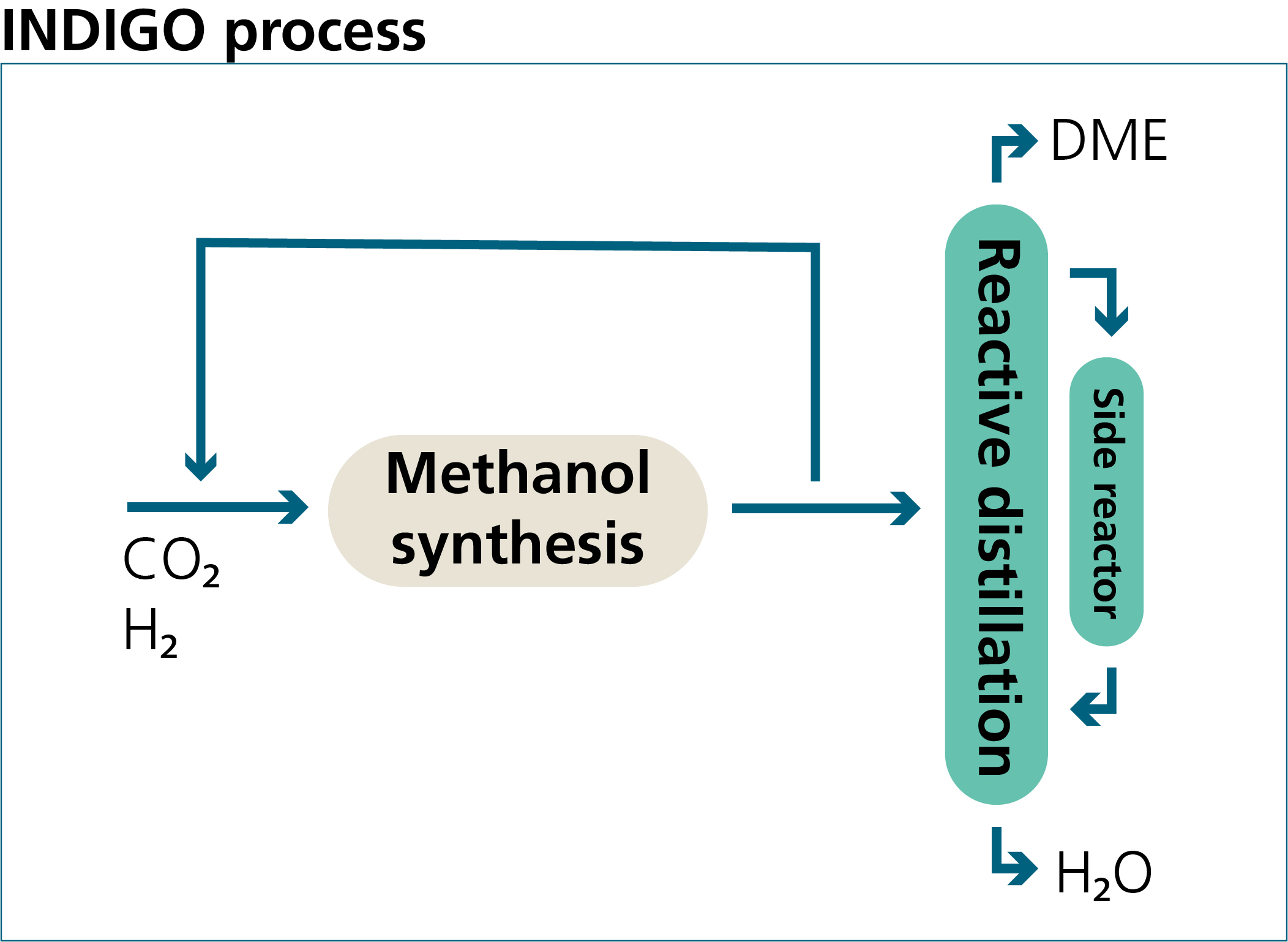

The INDIGO process developed at Fraunhofer ISE, which is based on reactive distillation, promises to increase efficiency and reduce costs. For a market launch of the process, however, it must first be proven that the functionality and benefits of the process are also ensured on a larger scale, as the construction of commercial chemical plants requires a considerable investment.

In cooperation with the industrial partner thyssenkrupp Uhde, the aim of the project is to increase the technological maturity of the innovative and efficient process developed by Fraunhofer ISE for the production of DME and to prepare its industrial implementation. To this end, investigations on a larger scale under real industrial conditions are essential.

Approach

We have developed a process for the production of DME by reactive distillation, which allows the complete conversion to DME in one step through simultaneous synthesis and distillation and thus an enormous process simplification compared to the conventional process.

The process also offers the following unique advantages:

- Use of crude methanol as feedstock without prior thermal treatment

- Integration of the heat-releasing reaction into the reactive distillation column → Energy self-sufficient process without external heat demand, which is therefore particularly suitable for geographical “sweet spots” for the generation of renewable electricity, which are often located in remote regions with little infrastructure

- Maximized process and cost efficiency as, unlike in the conventional processes, no energy is required to provide heat

- Use of a catalyst with up to 400% higher reaction rates than conventional catalysts

Specifically, the above project aims to scale up the process using a 7.5 m high reactive distillation column. Thanks to the high pressure stability of the system, the process can be investigated in the ideal operating range with maximum production output. In order to keep the commercial implementation as simple as possible, only industrially established components are used.

Real crude methanol is also used as a raw material, which in addition to the by-product water also contains a range of by-products from the previous methanol synthesis. The exact behavior of the by-products in the process is being investigated in detail.

Furthermore, the catalyst stability is to be investigated in more detail and industrially feasible operating strategies are to be developed which maximize the lifetime of the catalyst and thus contribute to minimizing manufacturing costs.

Publications

nicht entfernen!!