| Duration: | 10/2023 - 09/2027 |

| Contracting Authority/ Sponsors: | European Union |

| Project Partners: |

|

| Website: | Project Website CleanHyPro |

| Project Focus: | |

CleanHyPro – Open Innovation Test Bed for Electrolysis Materials for Clean Hydrogen Production

“CleanHyPro” is a project funded by the European Union to develop innovative electrolysis materials and components for sustainable and efficient hydrogen production. In the project, 28 organizations from 11 European countries are working on an open innovation test bed that offers industrial partners, especially small and medium enterprises (SME), access to innovative materials, advanced technologies and services to bring electrolysis technologies into application with minimal costs and risks. The aim of “CleanHyPro” is to expand and modernize nine existing pilot lines into a sustainable production system. Supplemented by technological and non-technological services, the project partners aim to support companies in the (further) development of marketable electrolysis materials and components.

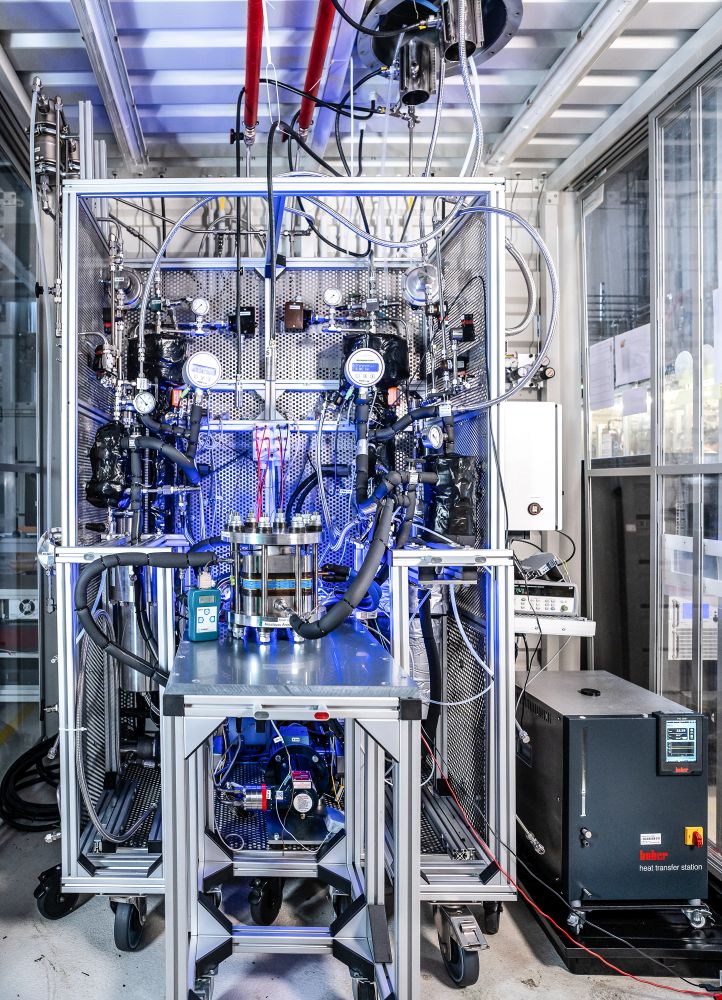

Fraunhofer ISE's focus in the “CleanHyPro” project is on the in-situ characterization of electrolysis materials and components. As part of the project, we are expanding our measurement capacities for the electrochemical in situ characterization of PEM electrolysis cells and stacks, e.g. through improved power electronics or additional measurement methods such as impedance measurements on stacks.

Based on this, we measure membrane electrode assemblies (MEAs) of the project partners with regard to their performance and ageing behaviour depending on the production parameters. The long-term stability of a PEM electrolysis stack developed jointly with project partners is also tested in a so-called showcase. This will allow us to gain valuable insights into novel MEA production methods such as atomic layer deposition and nanoprinting and derive optimizations for cell design and operational management.

In the second phase of the project, external companies can have their own components characterized by us with the help of the previously implemented showcase. This gives them a simple introduction to the application of their materials in a PEM electrolysis stack.

Thanks to our many years of experience, we can support you on the way to application in water electrolysis. If you are interested, please contact us!

Detailed information on the project, the consortium partners and the exact course of the project phases can be found on the official project website: https://cleanhypro.eu

This project has received funding from the European Union’s Horizon Europe research and innovation programme under the Grant Agreement No 101091777.