| Duration: | 12/2020 - 11/2023 |

| Contracting Authority/ Sponsors: |

Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | Heckert Solar GmbH; Teamtechnik Maschinen und Anlagen GmbH |

| Project Focus: |

KoMoGER – Competitive Modules "Made in Germany"

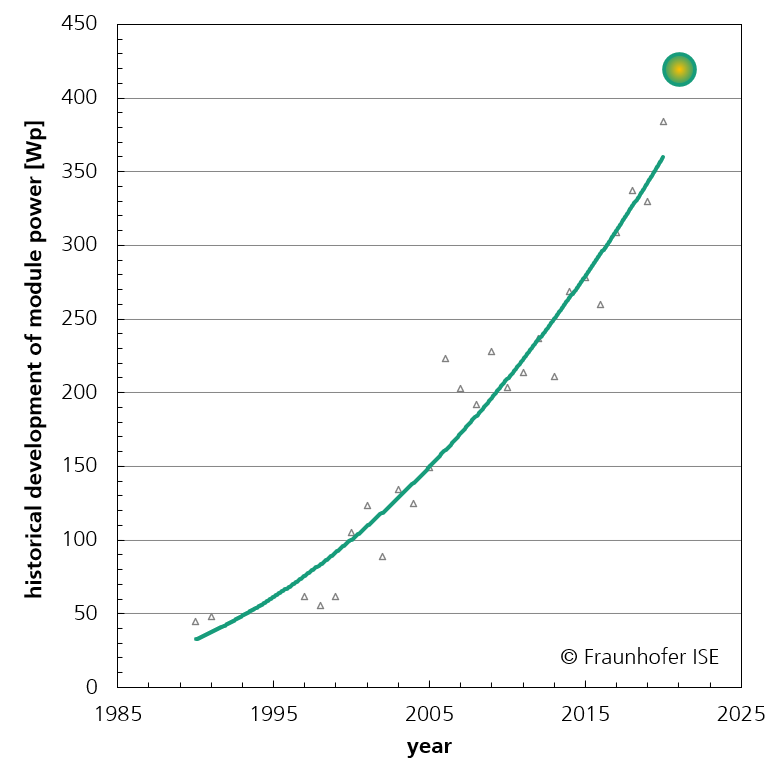

The aim of the "KoMoGER" project is to establish a future-proof PV module production facility at Heckert Solar in Chemnitz with an annual production capacity of an additional 400 MW. A module technology is being developed that enables the production of PV modules with an output of over 400 W. In addition, the aim is to increase the lifetime of the PV modules in order to reduce the cost of electricity. Another focus is the sustainability of the production and the manufactured PV modules. The carbon footprint is analyzed in order to work out suitable measures for reduction. The findings from cost accounting, carbon footprint, module design and plant development will be bundled in a concept for a module production "Made in Germany".

The module manufacturer Heckert Solar from Chemnitz plans to gradually expand its module production by an additional capacity of 400 megawatts/year. The capacity expansion is to be associated with a change in module design and further development of plant technology.

For this purpose, the project partners will develop an innovative module technology in successive steps, which enables module outputs of over 400 W per module in the final stage. During development, different cell formats, cell technologies, cell interconnection concepts and module designs will be combined and evaluated not only technically but also economically. The carbon footprint is also included in the evaluation. Not only the planned expansion stage is taken into account, but also a roadmap for further developments and the reduction of CO2 emissions is created.

Stringers from teamtechnik are used for cell interconnection during production. The project partner teamtechnik will further develop stringers for the interconnection of solar cells with more than 6 busbars and wire interconnection as well as the interconnection of solar cells in M12 format.

The project partners create a roadmap for the future-oriented development of PV modules and corresponding production facilities. Here, a future picture of the developments of the overall market, components and technologies is drafted and merged into a plan for the further development of local module production.

An analysis of the carbon footprint is carried out for production as well as for the equipment used and corresponding optimization potentials are evaluated. A roadmap for the reduction of CO2 emissions in the production of solar modules with the goal of CO2-neutral manufacturing will be developed (supply chain, production facilities, product optimization and in-house generation). The plants will be analyzed in detail in a cost calculation in order to derive measures to increase competitiveness.

The project includes:

a) Technology assessment (performance, cost, carbon footprint, market development),

b) Selection of appropriate technologies and design definition for the KoMoGER module and future production adaptations,

c) Process development in the area of soldering technologies

d) Process development in the area of encapsulation

e) Support of equipment development for production

f) Assurance of module reliability