| Project Focus: |

modulum – Novel Characterization Tool for Photovoltaics

Aiming at steadily reducing the levelized cost of electricity of PV power plants, state-of-the-art research and development in silicon photovoltaics must focus on material quality: This relates to feedstock quality, to the impact of the crystallization and wafering processes, and to the impact of the individual solar cell process on material quality. This focus requires accurate analysis techniques of efficiency-limiting electrical characteristics in all stages of solar cell production – ranging from crystallization to metallization. With “modulum”, Fraunhofer ISE launched a versatile characterization tool for accurate material and cell analyses based on harmonically modulated luminescence, thereby assisting customers in meeting future challenges in silicon PV research and development.

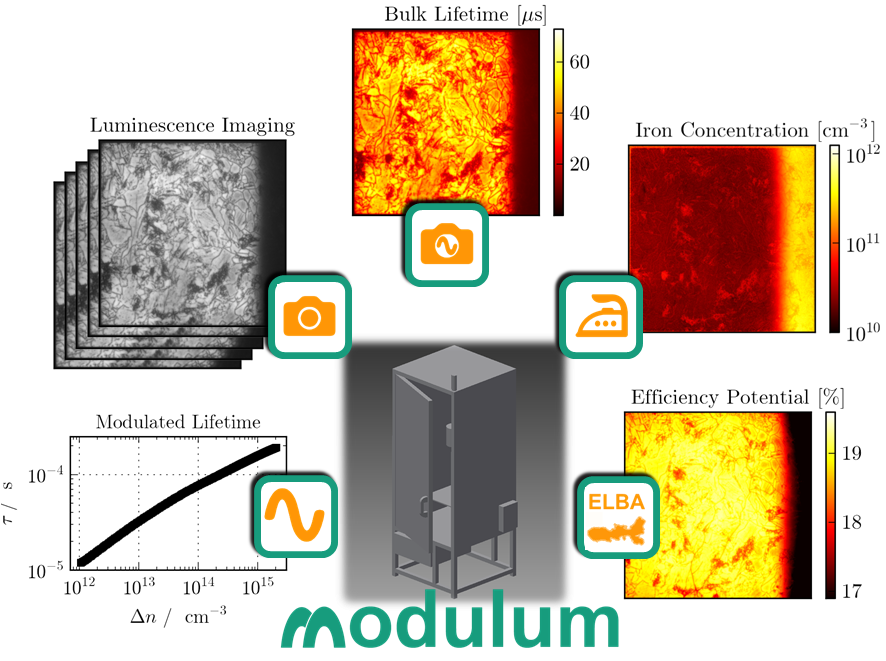

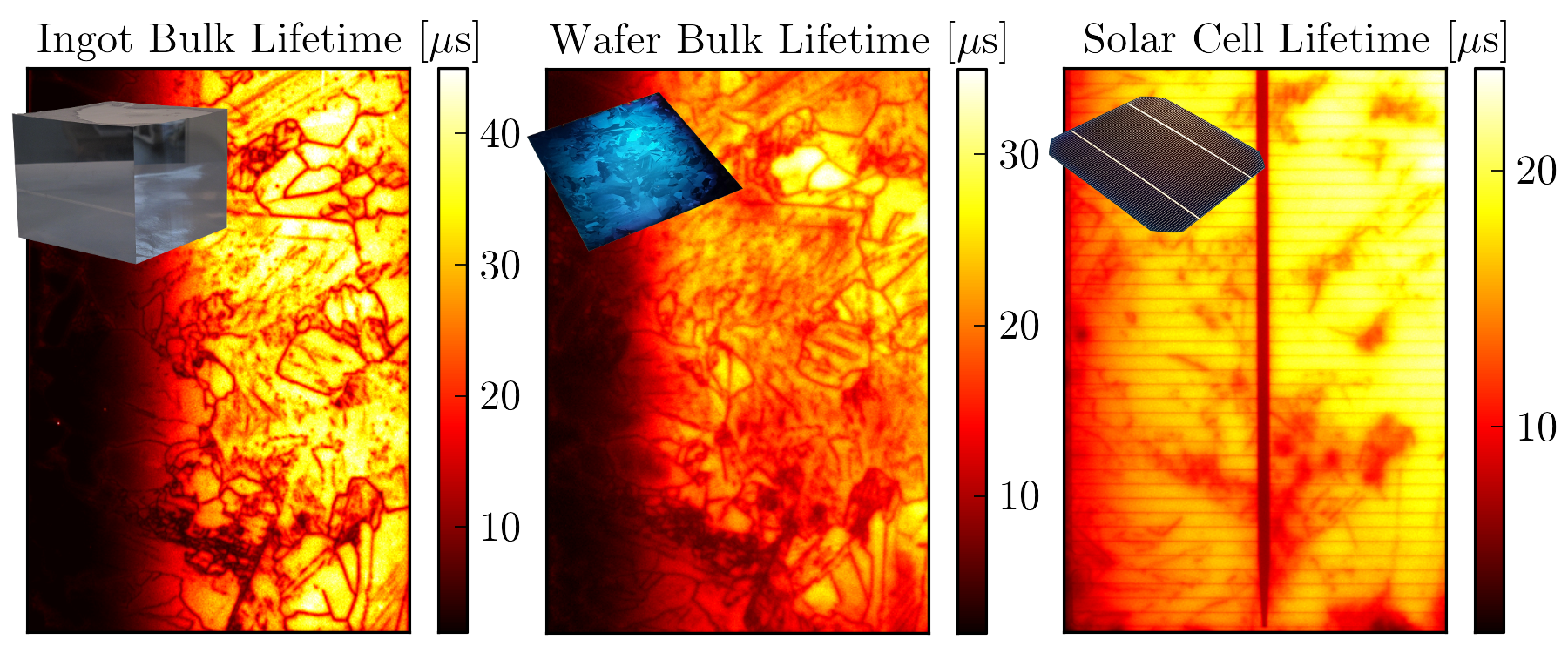

The silicon characterization tool modulum provides a broad variety of material and solar cell analyses based on the carrier lifetime calibration technique via harmonically modulated luminescence. In combination with integrated luminescence imaging capability, it allows both stand-alone injection-dependent carrier lifetime analyses as well as carrier lifetime imaging on silicon ingots, wafers, and solar cells. It thereby exploits the favorable characteristics of harmonically modulated luminescence, allowing process control based on the consistent and comparable parameter of carrier lifetime throughout the solar cell process.

Harmonically modulated luminescence is a dynamic carrier lifetime technique which requires a minimum of a priori assumptions, and which features particularly high sensitivity with respect to bulk lifetime on unpassivated material such as ingots. Its sensitivity ranges from sub-microseconds and excess carrier densities well below 1010 cm-3 up to the highest carrier lifetimes ever measured in silicon. Beyond carrier lifetime imaging and spectroscopy in all stages of the solar cell production process, modulum also incorporates a comprehensive efficiency potential analysis (efficiency limiting bulk recombination analysis, ELBA) as well as metastable defect imaging and recombination fraction analyses tailored to specific impurities such as e. g. interstitial iron.

The modular concept of modulum allows customers to easily integrate custom hardware components and software applications in order to match their individual R&D requirements.