| Duration: | 01/2023 - 12/2025 |

| Contracting Authority / Sponsors: |

Bundesministerium für Wirtschaft und Klimaschutz (BMWK) |

| Project Partners: | III/V-Reclaim, AZUR SPACE Solar Power GmbH, ICB GmbH & Co. KG, Karlsruher Institut für Technologie (KIT), LPKF Laser & Electronics SE, PROTAVIC INTERNATIONAL, SUNSET Energietechnik GmbH |

| Project Focus: |

Mod30plus – Cost-Efficient Processes for High-Efficiency III-V//Si Tandem Solar Modules with at Least 30% Efficiency

Tandem photovoltaics is one of the fastest developing fields of solar research today. In industry today, single-junction silicon solar cells are the state of the art. At Fraunhofer ISE, it has already been demonstrated that using layers of III-V compound semiconductors the Auger limit of silicon, which is 29.4% efficiency, can be surpassed. The most recent record is 36.1% (2023). The task now is to make the manufacturing processes required to produce these III-V//Si tandem solar cells more cost-effective and efficient and to scale them up further. The first goal of small series production is to realize a module prototype with an efficiency of more than 30%.

The continuous improvement of the efficiency of solar cells and the simultaneous reduction of costs are key objectives in photovoltaic research. In this project, the focus is on the development of cost-effective and efficient cell processes and interconnection technology for III-V//Si tandem solar cells. By combining III-V materials with different band gaps in a tandem stack on silicon, the solar spectrum is used more efficiently, leading to higher efficiencies than what is possible for single-junction solar cells. Previous work has already successfully demonstrated efficiencies over 36% on a laboratory scale. Further scaling and optimization steps are now required for the industrial adaptation of the technology.

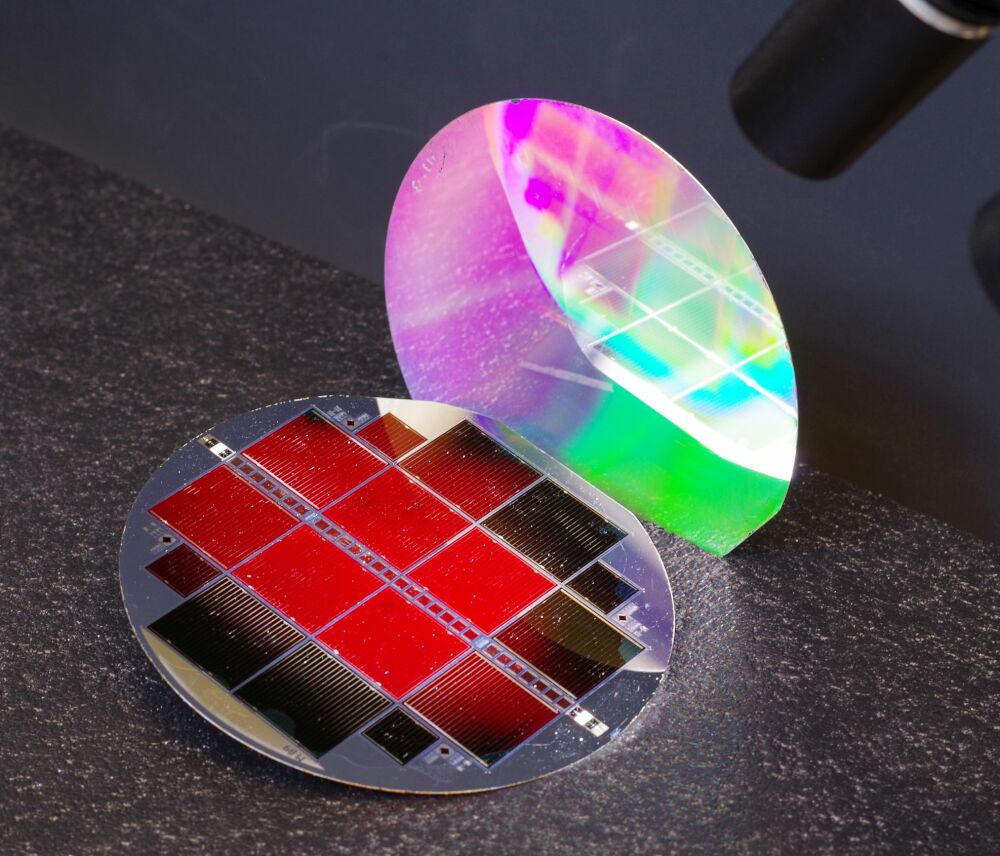

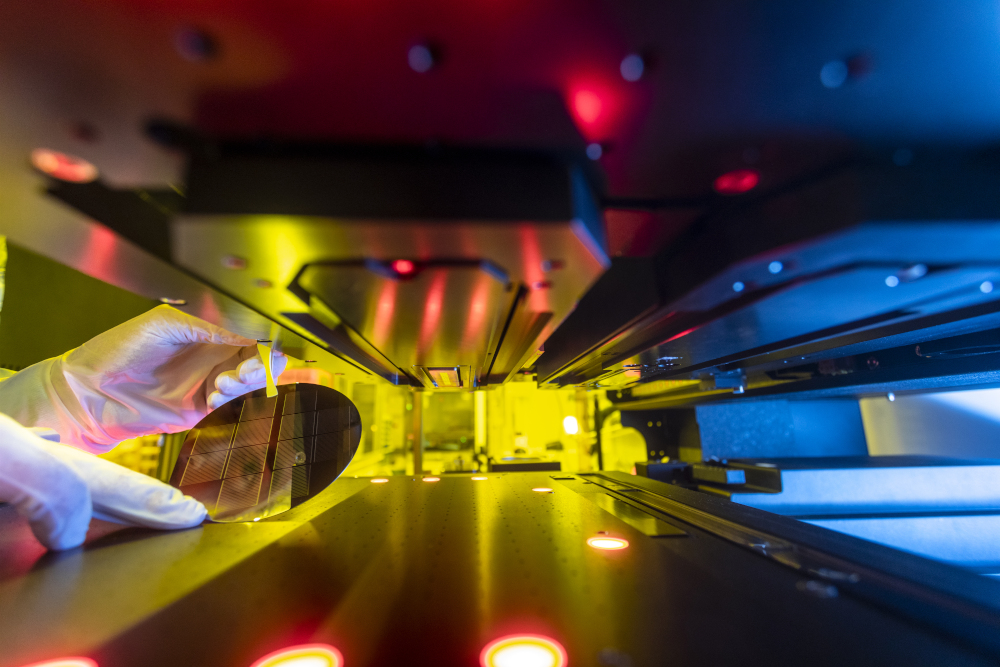

As part of the project, a module consisting of III-V//Si tandem solar cells with a module efficiency of more than 30% is to be realized. The shingle technology developed at Fraunhofer ISE will be used and combined with innovative, low-silver, conductive adhesives that are being further developed at KIT and PROTAVIC. In addition, SUNSET modules are realized with highly efficient tandem solar cells from AZUR in wire connection. To realize a sufficient number of tandem solar cells, the manufacturing process at Fraunhofer ISE is being scaled up from 4-inch to 6-inch wafers. Suitable polishing processes are also being developed by III/V-Reclaim, to connect the larger III-V and Si substrates. Furthermore, cost-effective processes in cell production are to be tested. A cost-effective alternative for texturing the silicon sub-cells is being investigated at Fraunhofer ISE and alternative metallization processes for the front-side electrodes are also being tested. On the one hand, LPKF and Fraunhofer ISE are further developing the stencil printing process. On the other hand, ICB and Fraunhofer ISE are investigating galvanic metal deposition as an alternative. The masks required for this are realized by inkjet printing. Fraunhofer ISE is also investigating the cost-effective deposition of anti-reflective coatings using spray pyrolysis.

Many of the issues addressed in the research project are not only relevant for III-V//Si tandem solar cells, but also offer added value for both conventional Si single-junction solar cells and III-V multi-junction solar cells.