| Duration: | 05/2023 - 04/2026 |

| Contracting Authority/Sponsors: | Project Sponsor Jülich (PTJ), Federal Ministry of Economic Affairs and Climate Action (BMWK) FKZ: 03EE1189 |

| Project Focus: |

LiverPool – Linear Evaporation Processes for Large-Area Industrially Scalable Perovskite-Silicon Tandem Solar Cells

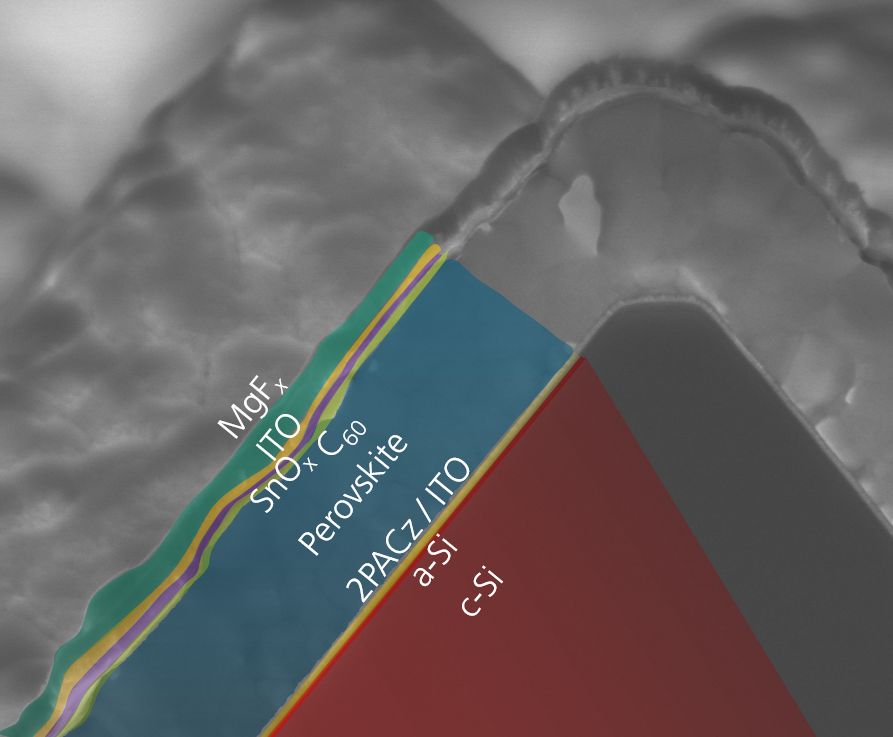

Perovskite-silicon tandem solar cells have the potential to become the successor to the previously dominant silicon solar cell. This technology has already been demonstrated on a laboratory scale. Efficiencies of over 30 % can be achieved on small-area solar cells. For tandem solar cells with textured silicon, the research focus is on evaporation processes for perovskite materials and contact layers, since it is not possible to conformally cover the pyramid structure of the silicon bottom cell with wet-chemical processes alone.

In the »LiverPool« project, industrially scalable evaporation processes for perovskite materials and contact layers are to be developed. For this purpose, an evaporation system is to be set up on which several M12 wafers (210 x 210 mm²) can be coated over the entire surface in one process step using processes as close as possible to series production.

In recent years, significant increases in efficiency have continued to be achieved for crystalline silicon solar cells. Nevertheless, the efficiencies of silicon single-junction solar cells are rapidly approaching the practically achievable limit of around 27%. For further efficiency increases, different solar cell materials can be combined to form tandem solar cells, which make better use of the solar spectrum by reducing the thermalization losses in the short-wavelength region.

Currently, perovskite-silicon tandem solar cells are mainly produced on a small scale in the laboratory. Typical cell areas are in the range of 1 cm² for the highest efficiencies. For the fabrication of these small laboratory cells, the method most commonly used is wet chemical spin coating. This method is practical for small laboratory formats and allows rapid testing of new material systems. However, spin coating is not scalable to industrial substrate sizes. In addition, spin coating cannot be applied to textured substrates, e.g., the pyramidal front side of silicon solar cells.

For industrial scalability, the research focus is therefore shifting to vacuum-based evaporation methods. Thus, the scientific and technical work objective of the project »LiverPool« is the development of scalable processes for the deposition of perovskites and contact materials using vacuum technology for perovskite-silicon tandem solar cells. For this purpose, an industrially scalable evaporation system will be procured and set up, enabling the production of tandem solar cells with a throughput of several M12 wafers per hour. In addition, the project team will develop evaporation processes for the hybrid route and use them to manufacture perovskite-silicon tandem solar cells on M12 silicon wafers.