| Duration: | 06/2024 - 05/2027 |

| Contratcting Authority / Sponsors: |

Bundesministerium für Wirtschaft und Klimaschutz (BMWK) (Funding indicator: 03ETE051C), PtJ |

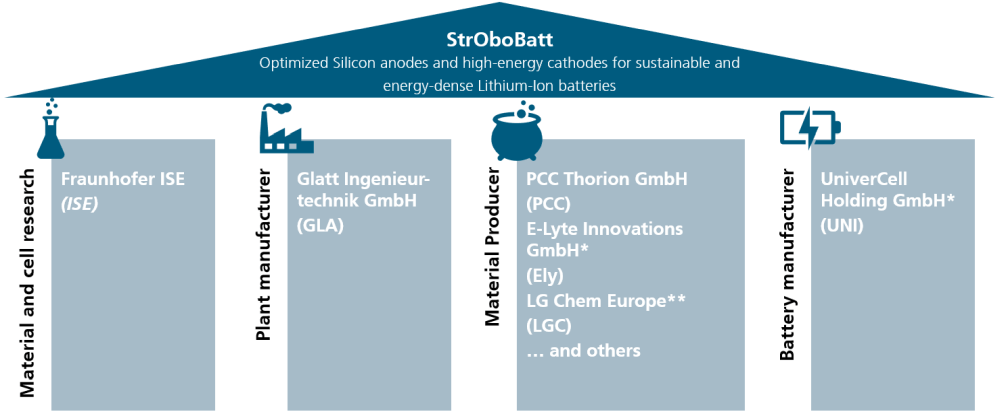

| Project Partners: | PCC Thorion GmbH, Glatt Ingenieurtechnik GmbH |

| Project Focus: |

StrOboBatt – Structure- and Surface-Optimized Silicon Anodes and High-Energy Cathodes for Energy-Dense Lithium-Ion Batteries

In the course of the expansion of renewable energy sources, the need for stationary storage systems will increase significantly in order to minimize the increasing volatility in electricity generation due to the continuous expansion of renewable energy sources such as photovoltaic and wind power plants. This requires a further increase in the attractiveness of electrochemical energy storage systems. The biggest points of criticism are still the (excessively) high acquisition cost, caused in particular by the high cost of the battery cells and the sustainability of the batteries with regard to critical raw materials.

All of these aspects are to be addressed in the “StrOboBatt” project. It focuses on the active materials themselves. The global dependence on certain raw materials is also to be minimized through the used materials and the sustainability of the battery cells is to be improved.

The overarching goal of StrOboBatt is to improve the energy density and sustainability of batteries through structural optimizations and surface refinements, while at the same time reducing production costs. The new and innovative research facility for batteries and storage systems at Fraunhofer ISE in Freiburg offers all project partners a modern development environment and an advanced infrastructure including two dry rooms.

Lithium-ion batteries used in mobility applications mostly use nickel-rich transition metal oxides with a high specific energy density on the cathode side. For stationary battery storage systems, cathode materials with an olivine structure (such as lithium iron phosphate: LFP for short) are predominantly used, which have significantly lower raw material prices, better cycle stability and can be produced more cost-effectively than transition metal oxides. On the anode side, the active material graphite is largely used, which has good electrochemical stability and low costs. Compared to graphite, silicon has a theoretical specific capacity that is ten times higher and can be used in structure-optimized silicon-carbon composites. This can significantly increase the energy density of the anode active material and reduce global dependence on graphite as a raw material. Value creation, especially in the extraction of raw materials, can thus be shifted to the EU.

- Material synthesis, structural and surface refinements of lithium (manganese) iron phosphate materials to reduce material and manufacturing costs, increase cycle stability and eliminate the elements nickel and cobalt, which are considered critical raw materials in the EU

- Production of silicon materials for use in silicon-carbon composites in order to at least double the energy density of the anode active material and shift the material value creation more towards the EU

- More cost-effective production of battery cells through aqueous cathode processing and dew point-reduced cell production

A pilot line will be available at Fraunhofer ISE for scaling up the developed processes, which includes active material synthesis, slurry and electrode production and battery cell assembly (pouch) including formation. The project's collaborative and development partners cover almost the entire value chain of lithium-ion batteries, from material development and scaling to industrial battery cell production and characterization: Fraunhofer ISE (material, process and cell development), Glatt Ingenieurtechnik (mechanical and plant engineering, material and process development), PCC Thorion (material production, material and process development, LG Chem Europe (material production), E-Lyte (material production) and UniverCell (industrial electrode production, cell assembly and formation).