| Duration: | 11/2022 - 12/2025 |

| Contracting Authority/ Sponsors: | Ministry of Economics, Labor and Tourism Baden-Württemberg |

| Project Partners: | Karlsruher Institut of Technology, University Stuttgart, associated Partner: Helmut Hechinger GmbH & Co. KG, acp Systems AG, Exyte Technology GmbH, Maschinenfabrik Gustav Eirich GmbH & Co. KG |

| Project Focus: |

PRONTO – Production of Sodium-Ion Batteries in Baden-Württemberg

In recent years, lithium-ion batteries (LIB) have been used to drive forward the electrification of various market sectors. However, in addition to socio-economic and ecological problem areas, supply chain problems, for example with the raw materials lithium and cobalt, are also coming to the fore. Sodium-ion battery (SIB) technology, on the other hand, allows critical raw materials to be dispensed with and can provide an alternative in a wide range of application areas.

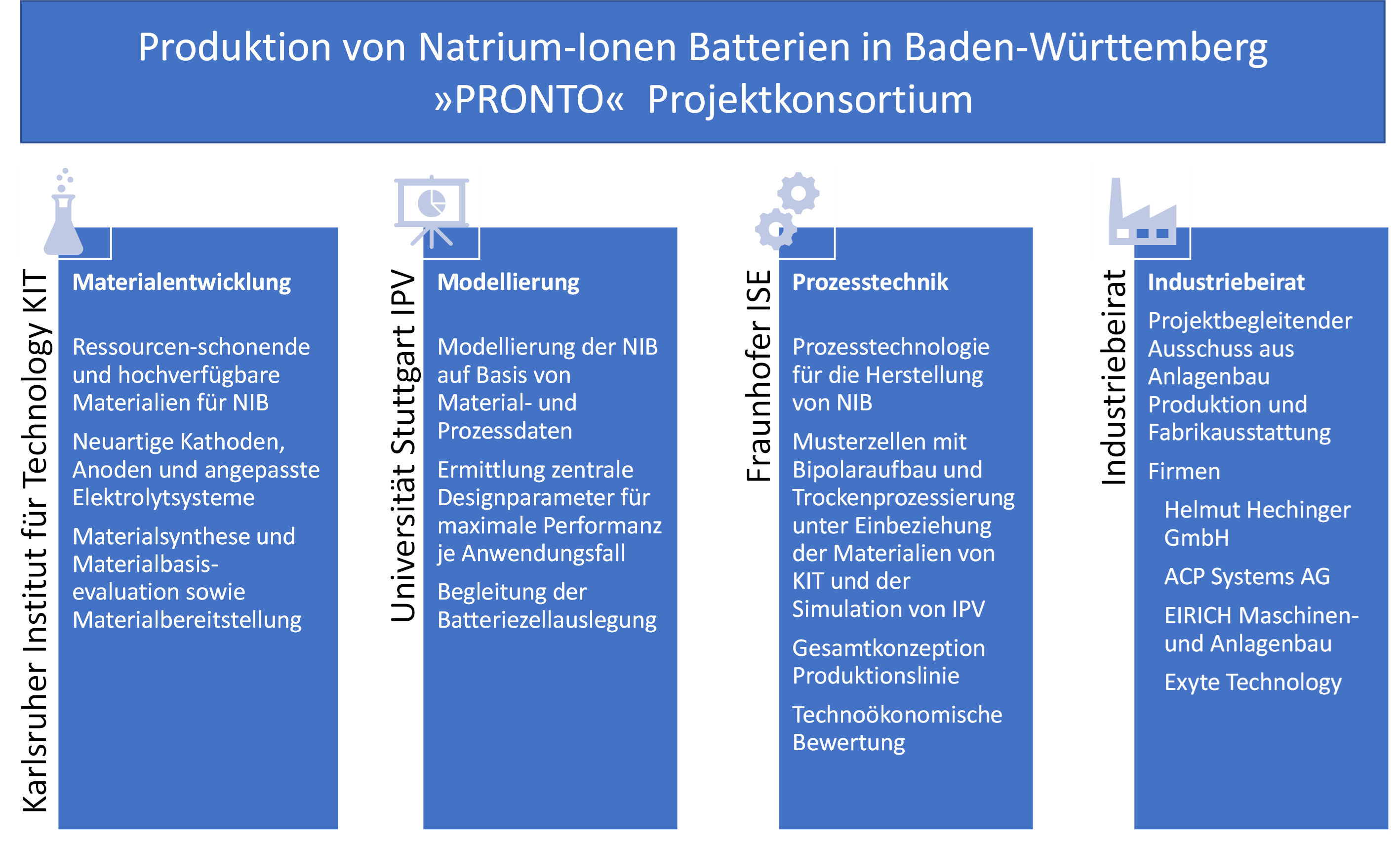

The PRONTO project aims to develop optimized active materials, high-performance battery cell architectures and scalable production processes for SIB that will allow battery cell production in the state Baden-Württemberg, Germany. The consortium consists of Fraunhofer ISE, the Karlsruhe Institute of Technology (KIT) and the University of Stuttgart and is accompanied by associated industrial partners.

Sodium-ion batteries (SIB) have become the focus of current research due to their low raw material costs, good temperature stability and improved (fast) charging capability. The inherently lower energy density compared to LIB of the cell chemistry can be partially compensated for by simplified system integration. Previous approaches are largely based on solvent-based doctor blade coating processes from the LIB field, which, however, are associated with high costs for drying, calendering of the electrodes and recovery of the critical, toxic solvents.

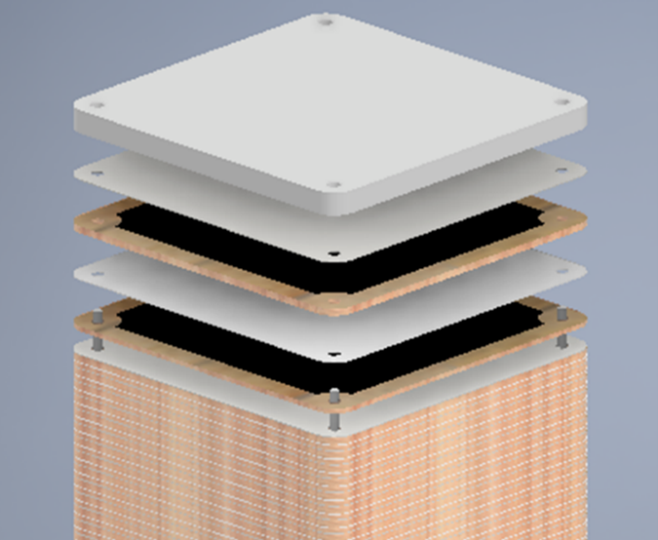

Based on previous experience of Fraunhofer ISE, this project will use an innovative and scalable dry coating process for the production of the electrodes, resulting in significant advantages in terms of cost, environmental balance and process integration. Furthermore, the envisioned cell architecture in large-scale bipolar design reduces costs and improves the modularity and recyclability of the cells.

At the same time, further research in the field of cell chemistry and its modeling is required at SIB. In this context, KIT contributes its extensive expertise in battery research to the material development of anode and cathode active materials, electrolytes, and their synthesis. The University of Stuttgart contributes the modeling of the SIB and thus determines design parameters that ensure the best possible performance of the cells for specific applications.

Fraunhofer ISE coordinates the project and develops the process technology for the production of SIB. Both small test cells for material tests and large-format cell formats close to the application are realized by dry processing, using the materials developed by KIT and the modeling of the University of Stuttgart. Based on this, an overall conception of a later production line and a techno-economic evaluation will be carried out at ISE.

As associated project members, the companies Helmut Hechinger GmbH, acp Systems AG, Maschinenfabrik Gustav Eirich GmbH & Co. KG and Exyte Technology GmbH are advising on the industry-related implementation of the research project.