| Duration: | 06/2023 - 05/2025 |

| Contracting Authority/ Sponsors: | Vector Stiftung |

| Project Focus: |

COFFEE – Cobalt-Free Solid-State Batteries with Sulfide Electrolytes

The all-solid‑state battery (ASSB) has enormous potential in the areas of sustainability, performance and safety, and can challenge or even replace the lithium-ion battery with liquid electrolyte in some market segments.

Sustainable and high-performance batteries are a key factor in the energy transition as well as in the transformation of the transport sectors. To make a relevant contribution, batteries must be suitable for the broad market and thus affordable.

Especially for active materials, there are opportunities to advance ASSB. Therefore, in the »COFFEE« project, we are working on producing active materials that, in combination with ASSB technology, will make tomorrow's e-mobility more sustainable and affordable for everyone.

In a commercially available lithium-ion battery with liquid electrolyte, decomposition reactions of certain electrolyte components take place at both the negative and the positive electrode. These decomposition reactions are necessary in part because without them battery operation would not be possible. In addition to the intentional formation of SEI at the negative electrode, decomposition products of the electrolyte also have an influence on the positive electrode. Among other things, these lead to degradation of the active material, resulting in a steady reduction in usable capacity and eventual battery failure.

Specifically, the decomposition products lead, among other things, to parts of the active material dissolving in the electrolyte. In the case of the very frequently used NMC materials (LiNixMyCozO2), the manganese is particularly susceptible to this. In order to avoid the expensive, toxic and comparatively rare metal cobalt in favor of sustainability and costs, active materials with a very high manganese content are often used (e.g. LNMO, LiNi0.5Mn1.5O4). Therefore, many works deal with the application of protective layers on the active material to prevent the manganese from dissolving out of the active material. The same problem occurs with many sustainable active materials that use other elements instead of cobalt.

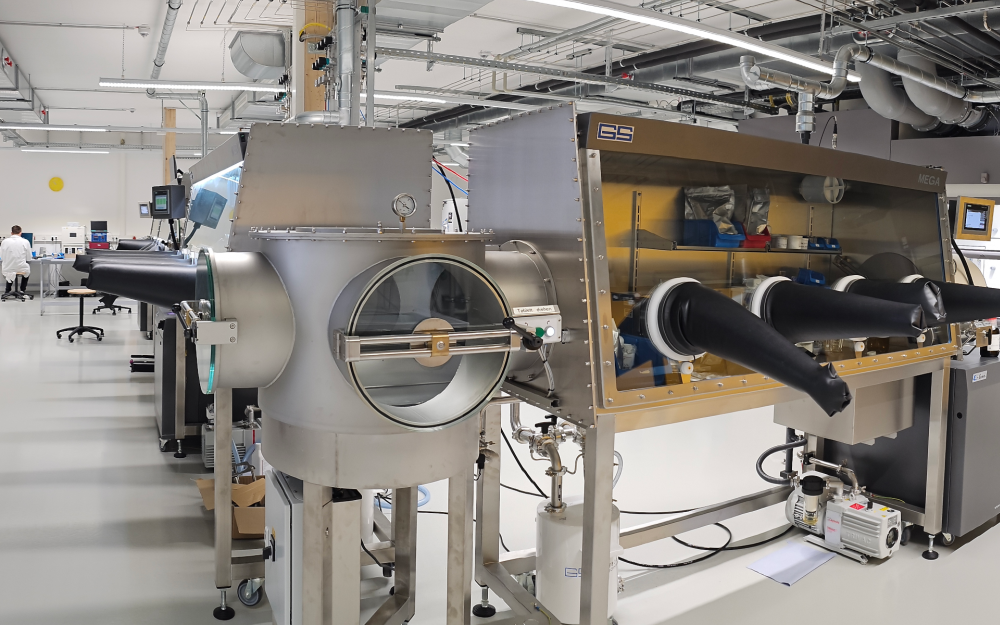

In the COFFEE project, we are pursuing the strategy of replacing the liquid phase (liquid electrolyte), which is responsible for the dissolution of the sustainable elements, with a solid phase (solid electrolyte). Thus, dissolution can no longer take place. In a first step, the aim is to develop an active material with a very high content of sustainable elements for the positive electrode. In this project, the utilization of cobalt is to be completely eliminated, and a cost-effective and resource-saving process is to be used. The corresponding active material will then be integrated into an ASSB with solid-state sulfidic electrolyte. Sulfidic electrolytes are ideal because they have high conductivity for Li‑Ions, are easy to process, and often consist of sustainable elements.

Thus, in the course of the COFFEE project, a novel ASSB will be developed, which is sustainable from source to cell and offers an alternative to current battery systems for upcoming applications, especially in the transportation sector.