| Duration: | December 2012 - November 2015 |

| Contracting Authority/ Sponsors: | Projektträger Karlsruhe |

| Project Partners: | Dekra SE, Fact GmbH |

Latent Heat Storage in Net Reactive Buildings

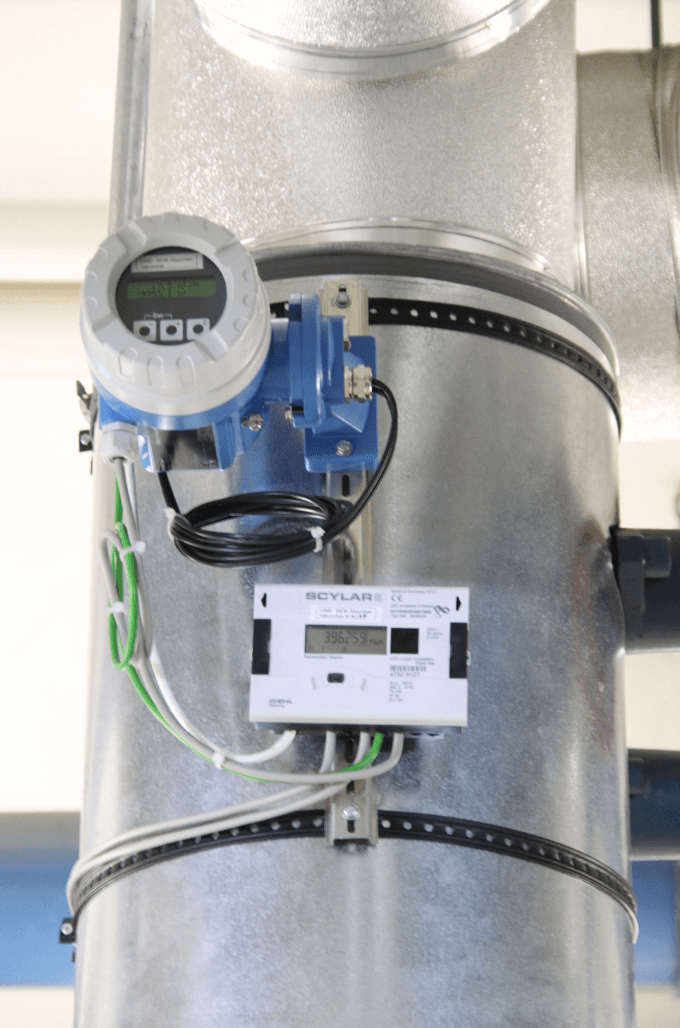

The head office of a medium-sized company is being modernized and extended. In this context, the energy system, which supplies the properties with heat, cold and electricity, is also completely redesigned. In the first step, a comprehensive monitoring system was installed, which allows for a detailed measurement and analysis of all significant energy flows within the system. Based the insight on the behavior or the system, a concept for integrating an innovative phase-change cold storage for increasing system flexibility and efficiency is developed. In order to achieve this goal, the whole system is modeled in a dynamic simulation environment and different storage and operation concepts are tested. Finally, the phase change cold storage is implemented according to the favored concept and monitored in real-life system operation.

At the heart of the energy system are three Combined Heat and Power (CHP) units, which produce electricity and heat locally for use in the headquarters. An absorption chiller is used to convert excess heat into cold. A gas boiler as well as an electrically driven compression heat pump cover the peak loads. In the course of the transition of the head office, during which three more buildings will be integrated into the campus, further heat and cold generators will complement the system. In order to extenuate and exploit intraday fluctuations in heat, cold and electricity demand, a customized storage and operation concept is developed based on measured energy flows and dynamic simulation studies. The storage concept comprises a phase-change cold storage with a paraffin-water mixture. One main benefit of this technology is its high energy density, which allows a far better utilization of the limited space in the facility than conventional thermal storages. After implementation of the storage in the headquarters, its behavior will be monitored in real system operation. The findings of this project will be used for further development of phase-change storages.