| Duration: | 06/2018 - 05/2020 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Focus: |

EmitterPlus

Integrated Process for Formation of Gas-Phase Emitters and Selective Contacts

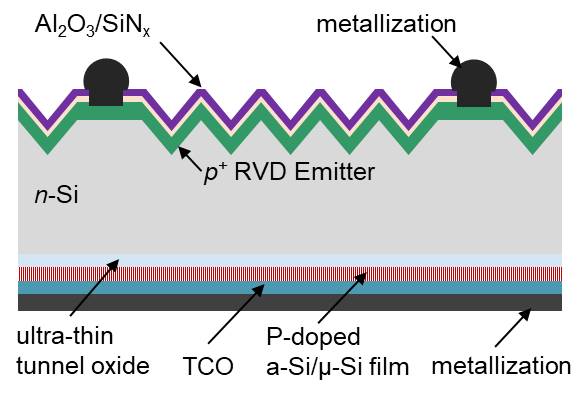

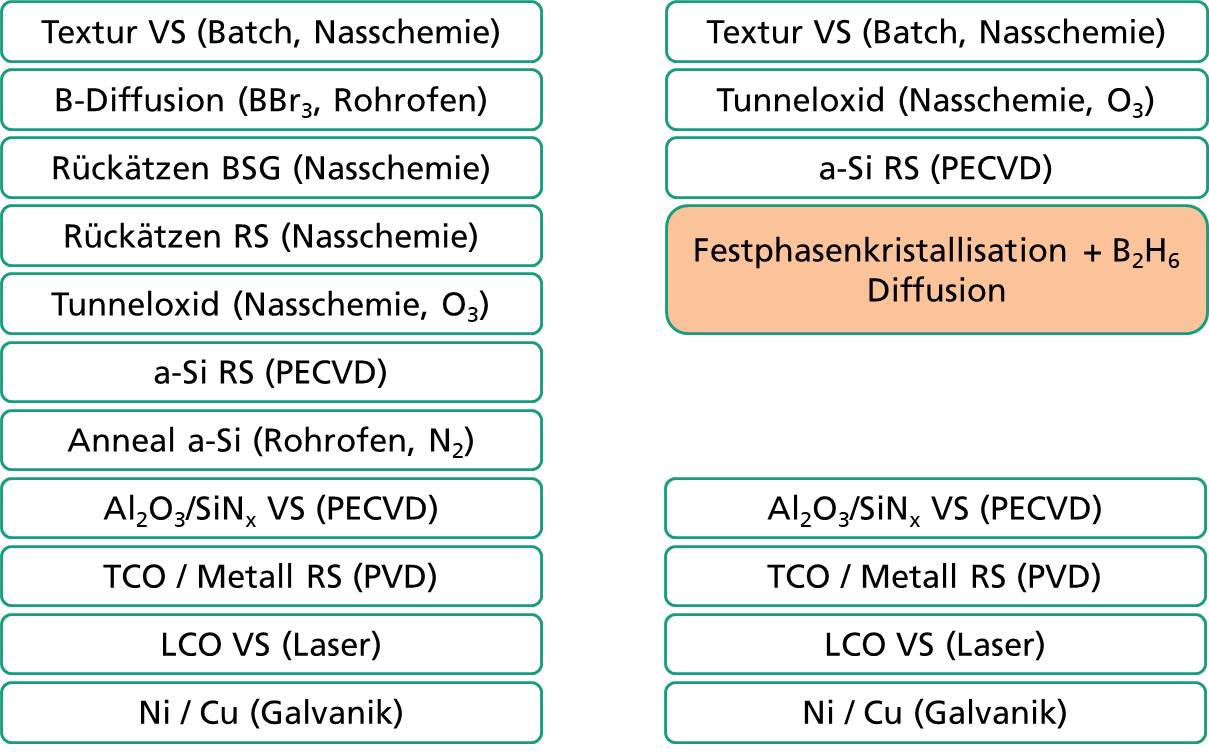

In the project »EmitterPlus«, gas phase emitters (RVD: rapid vapor-phase direct doping) are investigated as an alternative to conventional emitters in solar cells with selective contacts (TOPCon: tunnel oxide passivated contacts). The aim is to develop an integrated process for emitter diffusion and annealing of the selective contacts, with which solar cells can be produced with an efficiency of 25%. For this purpose, existing processes will be adapted and further developed. In addition to the demonstration of highly efficient solar cells, the process and machine know-how necessary for an industrial implementation of the gas phase emitter process will be generated in order to subsequently develop the industrial implementation together with machine builders.

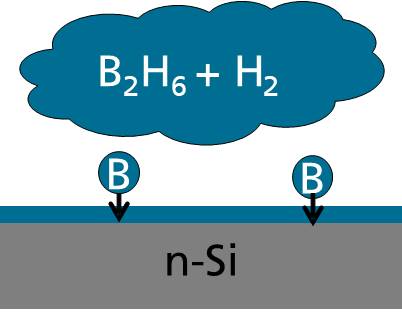

Diffusion of the emitter is an important standard technology in the production of solar cells. For this purpose deposited doping glass must be etched to produce a highly efficient solar cell. This can be avoided by using a gas phase emitter (RVD) in which the emitter diffuses directly from the gas phase into the wafer without forming a glass layer. An additional advantage of this gas phase emitter is that the concentration of the dopant offered can be changed during the process. As part of “EmitterPlus”, this approach is to be used in solar cells with selective contacts (TOPCon). The high temperature step necessary for the anneal of the selective contacts is to be integrated into the gas phase emitter process. By adjusting the tunnel oxides, a wide temperature range can be used, allowing adaptation of the process windows for emitter diffusion and anneal of the selective contacts. The simultaneous optimization of both processes is therefore an essential part of the project.

The aim of EmitterPlus is to demonstrate the technological feasibility of the overall process (RVD emitter and TOPCon crystallization layer) using solar cells (target efficiency 25%) and, thus, to further shorten the process chain for the production of highly efficient solar cells with passivating contacts and, thus, to reduce manufacturing costs. In addition, the process and machine know-how necessary for an industrial implementation of the gas phase emitter process is generated through preliminary tests in order to subsequently develop the industrial implementation in cooperation with mechanical engineers.