| Duration: | 08/2022 - 06/2026 |

| Contracting Authority/ Sponsors: | Federal Ministry of Education and Research |

| Project Partners: | University Ulm; Associated: Fukushima Renewable Energy Institute, AIST (FREA), Clariant Produkte (Deutschland) GmbH |

| Project Focus: |

PICASO – Novel power-to-ammonia process for sustainable ammonia synthesis

Process Intensification & Advanced Catalysis for Ammonia Sustainable Optimized Process

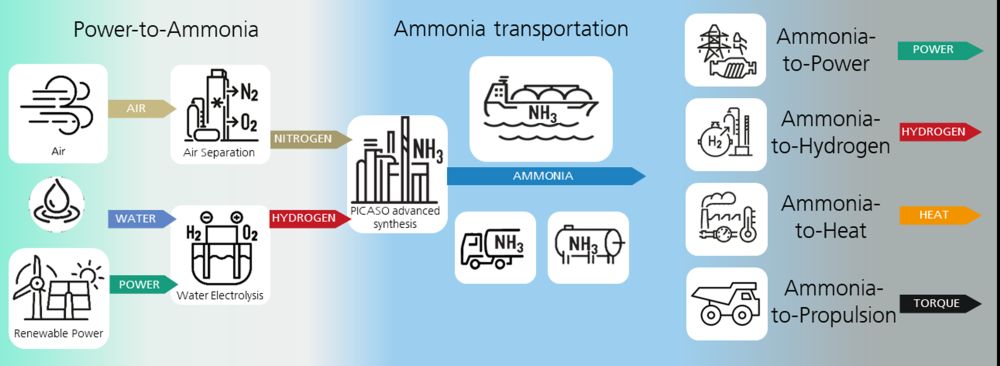

Green ammonia is a small molecule with high economic potential. It is obtained from green hydrogen and atmospheric nitrogen and can be used as a chemical feedstock, in agriculture, as a hydrogen carrier and directly as a fuel or to generate electricity. Among other things, green ammonia will be able to significantly contribute to the energy transition, as it can be transported from sunny and windy regions to Germany and Europe.

In the “PICASO” (Process Intensification & Advanced Catalysis for Ammonia Sustainable Optimized Process) project, Fraunhofer ISE is working together with the University of Ulm and the Fukushima Renewable Energy Institute until 2025 on a novel power-to-ammonia process (PtA) for sustainable, resource-conserving ammonia synthesis. The background to this is that in the conventional Haber-Bosch process, hydrogen and nitrogen are not completely converted to ammonia due to thermodynamic limitations and have to be recycled at great expense. The process is therefore associated with losses of hydrogen and nitrogen and also requires a complex infrastructure.

The aim of the PICASO approach is to develop an integrated reactor technology and customized operating strategies that allow milder reaction conditions, in particular lower operating pressures and temperatures. The proportion of unreacted hydrogen and nitrogen is to be reduced by so-called in-situ adsorption. This means that the ammonia is produced directly in the reactor itself, where it is absorbed by a suitable solid. “This combining of the reaction and the material separation can overcome the thermodynamic limitations and increase the material and energy efficiency of the entire PtA process,” explains Malte Semmel, Head of Group, Separation and Production Technologies. At the same time, the investment costs for new plants can be significantly reduced as, ideally, there is no need for laborious gas recirculation and compression. This means that in future, the technology can also be used economically in remote regions with high renewable energy potential or even offshore – i.e., decentralized and on a smaller scale.

In exploring the reaction to synthesize ammonia using a ruthenium catalyst, the focus is, among other aspects, on the development of detailed reaction engineering models. In addition, suitable materials for the selective separation of ammonia will be investigated and developed. The innovative integrated reactor concept will then be investigated experimentally on an industrially relevant scale. Dynamic experiments will be carried out covering all process steps – reaction, adsorption, and desorption – with the aim of developing dynamic operating strategies. The transfer of the technology developed at Fraunhofer ISE into a process simulation platform enables cost and resource savings to be quantified using techno-economic and life cycle assessments.

A new era for sustainable synthesis

Researchers at Fraunhofer ISE and the University of Ulm have achieved a significant milestone in the production of green ammonia: they have set up and launched a unique technological process to optimize the process of ammonia synthesis. They will then use the knowledge gained to develop and test a novel reactor concept.

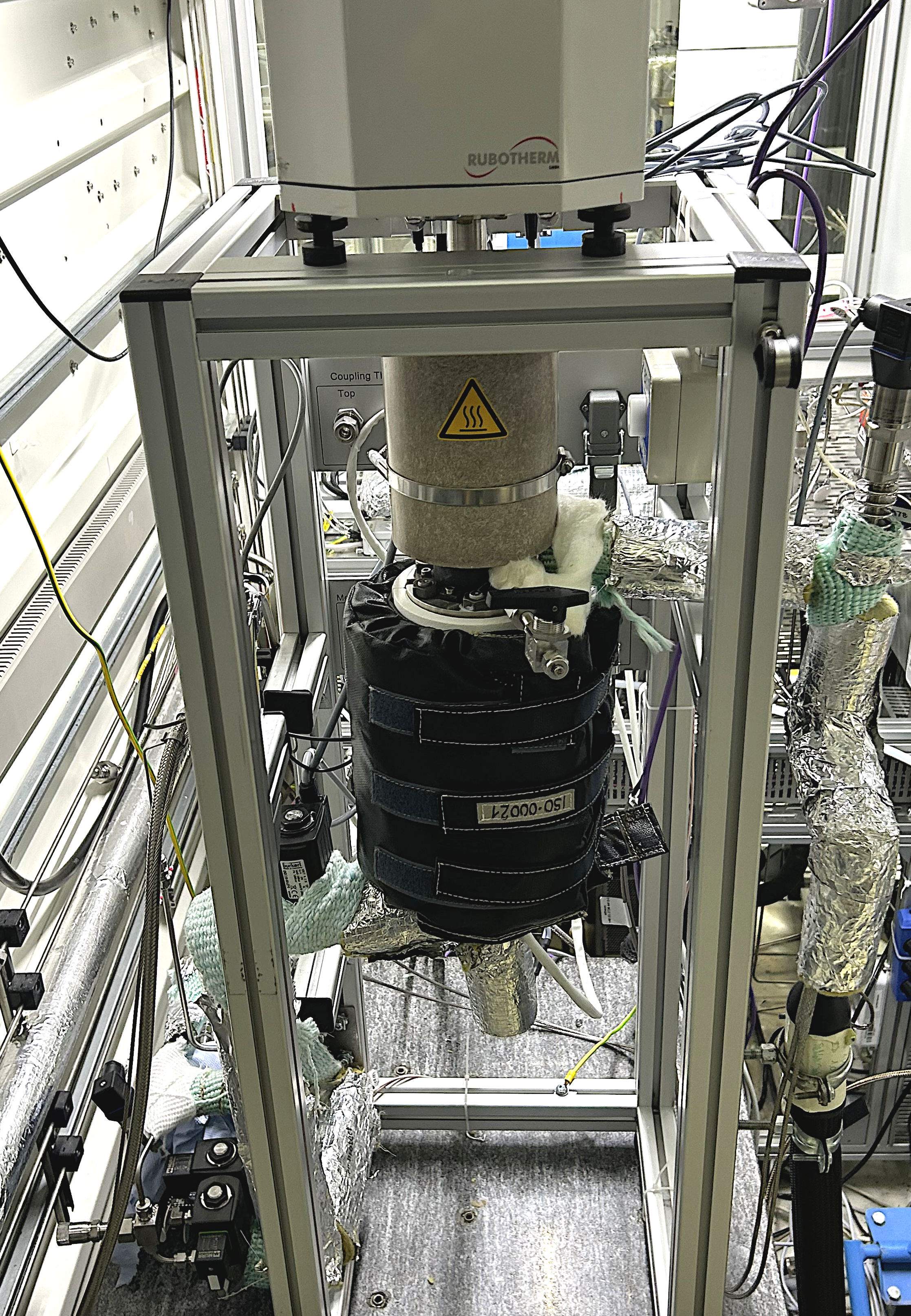

In order to optimize materials for use in PICASO technology, they have installed a high-temperature and high-pressure magnetic levitation chamber and a dosing system designed and manufactured in-house at the Fraunhofer Institute for Solar Energy Systems ISE. This enables them to measure ammonia adsorption at temperatures of up to 500 °C and pressures of up to 80 bar. This makes them the first research group in the world that can investigate ammonia adsorption under synthesis conditions in a wide parameter window and use automated methods to measure and understand sorption kinetics.

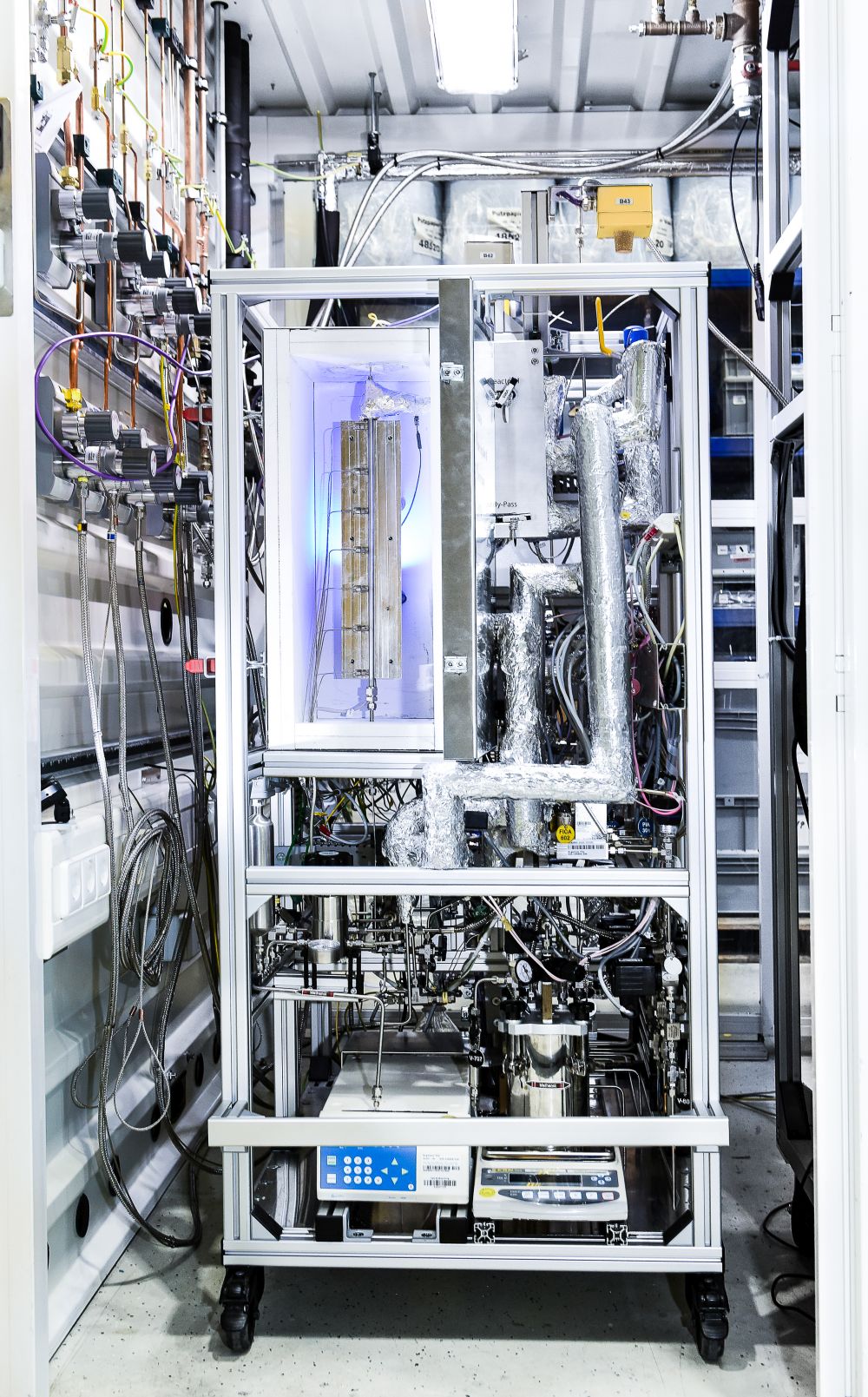

At the same time, the team at the University of Ulm has set up a test facility for the experimental investigation of synthesis, sorption and decomposition under real conditions. This allows the PICASO concept to be tested and further developed under defined conditions. The facility also offers the opportunity to simulate the path of ammonia as a so-called hydrogen vector, as the essential process steps can be modeled. The experimental data will be unsed to develop a mathematical reactor model that we can use to design and optimize the integrated reactor concept.

The project aims to transfer the new PtA concept from laboratory to pilot scale. While the focus at the University of Ulm is on the laboratory scale, Fraunhofer ISE is carrying out extensive experimental studies at the technical pilot scale. Detailed mathematical modeling and simulation will then be used to link and validate both scales so that reliable predictions can then be made for scaling up. In addition to the technical demonstration, the partners also want to prove that the novel, flexible PtA process is economically competitive with the conventional process.

Links and Downloads

- News 2022/09: Ammonia as a Hydrogen Vehicle: New Integrated Reactor Technology for the Energy Transition (ise.fraunhofer.de)

- Article ChemEngineering 2022, 6(1), 13: Process Intensification Strategies for Power-to-X Technologies

- Press Release 2022/03: Fraunhofer ISE develops mobile test stand for high-resolution Power-to-X kinetic analysis