| Duration: | 12/2024 - 11/2025 |

| Contracting Authority/ Sponsors: |

|

| Project Partners: |

Associated partners:

|

| Project Focus: |

E-Fuels for the LÄND – CO2 Direct Air Capture and DME Synthesis as Key Technologies for E-Fuels

In the “E-Fuels for the LÄND” project, three scenarios for the production of sustainable fuels for aircraft and vehicles are being examined in detail as part of a feasibility study, taking into account maximum value creation in Baden-Württemberg, resilient business models and a rapid market ramp-up.

Background:

The defossilization of the transport sector is one of the greatest challenges for climate protection. In Germany, no significant emission reductions have been achieved in this sector in recent decades. Hydrogen and its derivatives such as dimethyl ether (DME) could contribute to greenhouse gas reduction as so-called renewable energy fuels (reFuels).

The production of these fuels must be based exclusively on renewable electricity and carbon from sustainable sources or from the air. In order to produce synthetic fuels on an industrial scale, the known manufacturing processes and technologies must be scaled up and further research is needed. However, economic, regulatory and structural policy challenges must be overcome for the industrial scaling and market ramp-up of synthetic fuels.

The Baden-Württemberg Ministry of Transport has commissioned a project consortium from science and industry to conduct a feasibility study for the production of sustainable fuels in and for Baden-Württemberg. Experimentally based techno-economic calculations will show the potential of innovative processes and demonstrate their influence on production costs in sensitivity analyses and comparisons.

Solution:

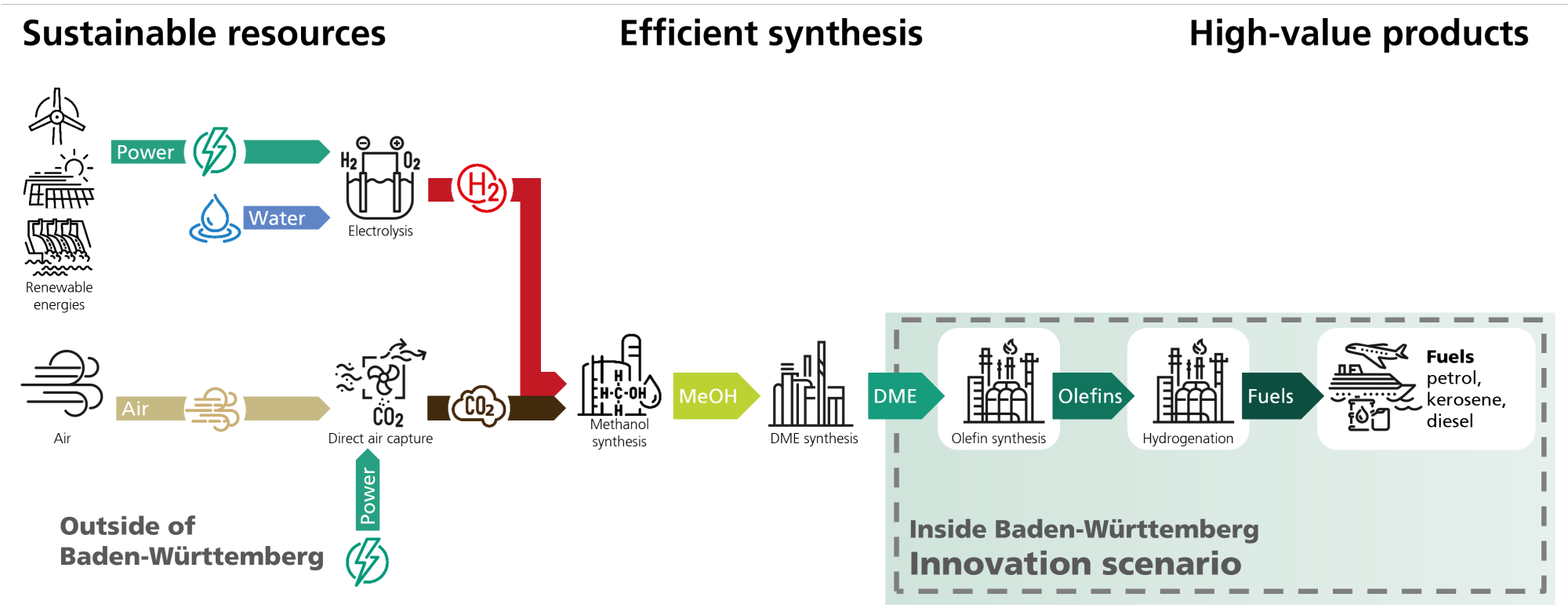

We are investigating the entire value chain of sustainable fuels: from production from hydrogen and carbon dioxide extracted from the air (Direct Air Capture, DAC) via the intermediate products methanol and dimethyl ether to gasoline or kerosene.

In the project, the hydrogen carrier dimethyl ether is considered a central intermediate product. DME is non-toxic, has a high energy density and great potential for the efficient production of fuels and products for the chemical industry. DME could also be used as an energy carrier.

Methodology:

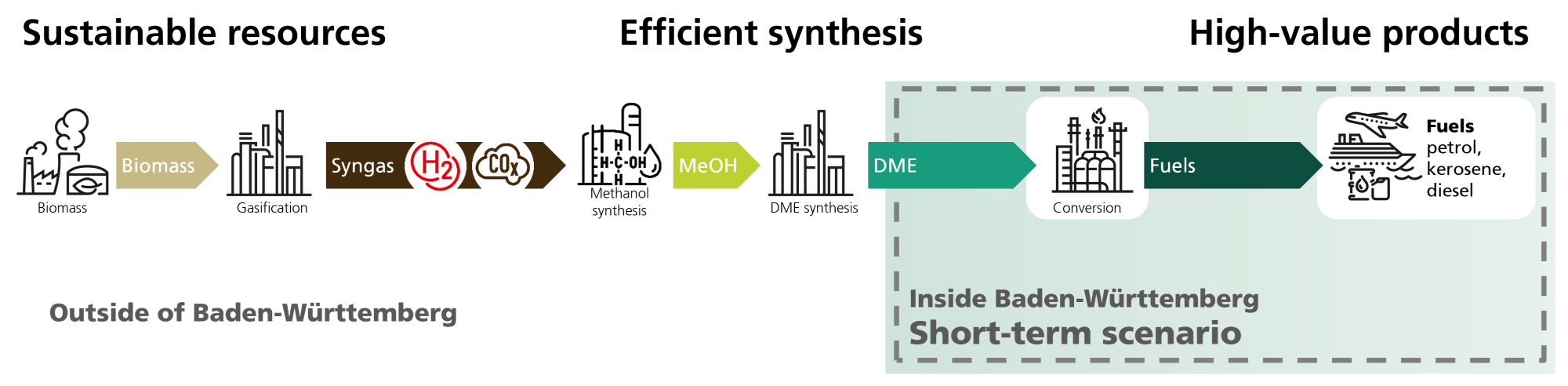

The project will analyze various scenarios that map the transformation towards large-scale e-fuel supply. The first scenario describes the short-term perspective, in which biomass is used as a raw material and converted into fuels using known, scalable technology (see Figure 1). Since the availability of biomass is limited, the value chain is extended to include a CO2 direct air capture process in the medium and long-term scenario. The industrial partner Purem contributes its expertise in mechanical engineering, metal processing and materials science to practical and theoretical work on CO2 direct air capture modules. The Fraunhofer ISE team is conducting experimental investigations to gain a better understanding of CO2 direct air capture and new DME synthesis processes. One step in the new value chain in the medium and long-term scenario is the INDIGO process, a manufacturing process for DME for which Fraunhofer ISE has applied for a patent. The process enables efficient and cost-effective DME production from raw methanol. In addition, DME synthesis and the DME-to-olefins process are being investigated to optimize the production of high-quality fuels such as kerosene and gasoline (see Figure 2). At the KIT, experimental investigations are being carried out into fuel production and refinement from DME and described using process models. In addition, the Fraunhofer IAO is investigating employment effects along the value chain of hydrogen, CO2, DME and reFuels.

Goal:

Detailed techno-economic analyses are used to identify and quantify optimization potential in order to create a viable business case for the production of e-fuels in Baden-Württemberg. The results of the project should not only secure industrial value creation in Baden-Württemberg, but also contribute to achieving global climate goals and maintaining regional jobs.

The project “E-Fuels for the LÄND” is funded by the Ministry of Transportation Baden-Württemberg.