| Duration: | 05/2018 - 04/2021 |

| Contracting Authority/ Sponsors: | Vector Stiftung |

| Project Focus: |

Printsolid – Printable Solid-State Lithium-Ion Batteries

Lithium-ion batteries are key to the successful implementation of the energy transition, especially in the transportation sector (e-mobility). Present-day batteries that rely on liquid electrolytes still pose a residual risk of so-called “thermal runaway”. Improvements in energy density are also desirable as they would allow for greater range.

Switching to solid ionic conductors not only significantly improves safety, it also makes it easier to use lithium metal anodes, which can improve the energy density of the batteries considerably.

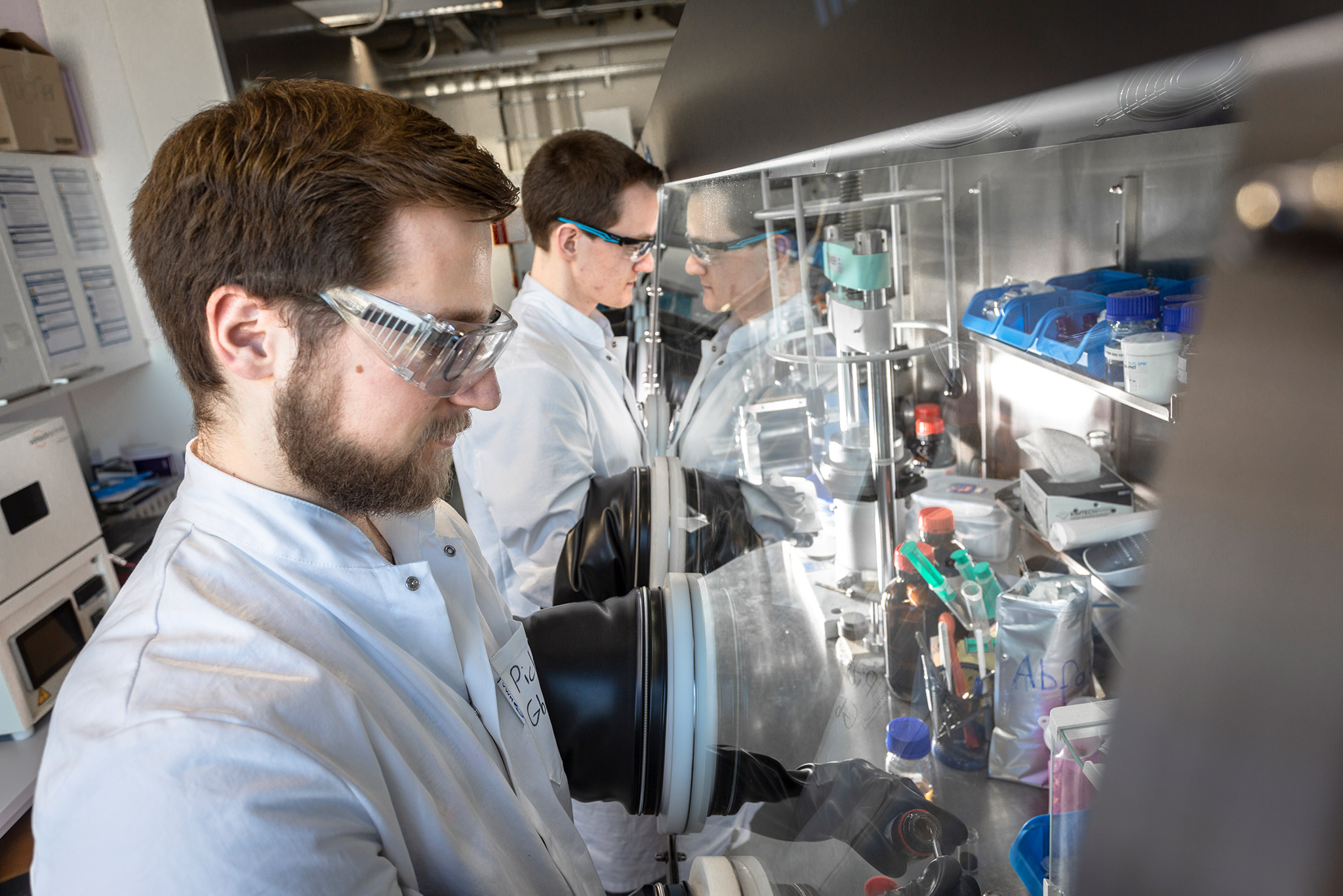

While a variety of different materials can be used for solid ionic conductors (polymers, oxide or sulfide-based ceramics or glass), this project relies on sulfidebased ionic conductors because they offer high ionic conductivity and can be processed inexpensively.

The goal is to develop an inherently safe and environmentally friendly “all-solid-state” lithium battery, characterized by a very high energy density that exceeds the capabilities of the current generation of batteries. In order to make cost-efficient production possible, sulfide-based solid ionic conductors will be used. To this end, Fraunhofer ISE is developing a process for printing both the electrodes and the ion-conducting separator layer.

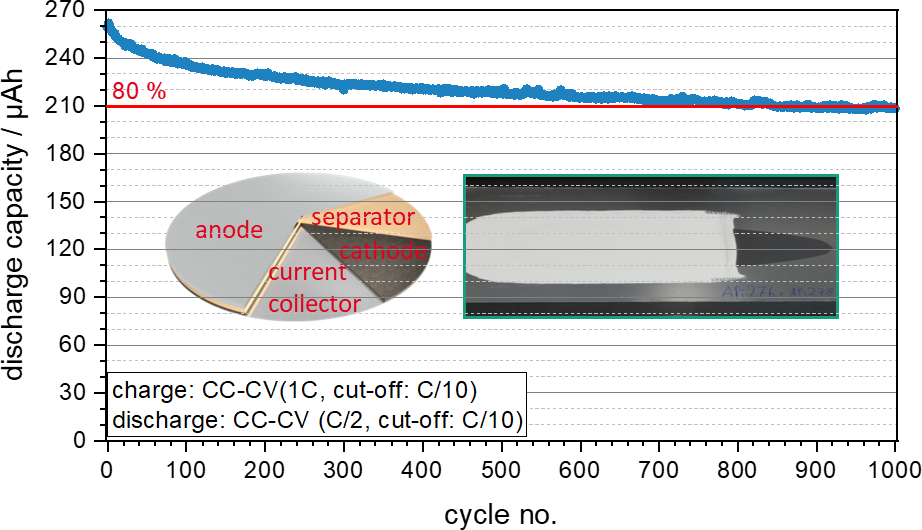

One impressive recent outcome is the production of battery cells in which both the cathode and the separator layer were prepared using printing processes. These batteries have thus far demonstrated outstanding cycling stability (> 1000 cycles), retaining 80% of their initial capacity of 140 mAh/g(NCM) with comparatively high charging and discharging currents (charging at 1C, discharging at C/2).