| Duration: | 5/2019 - 4/2021 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | Deutsches Zentrum für Luft- und Raumfahrt e.V. (DLR) |

| Project Focus: |

SOLSEC – Secondary Reflectors for Solar Power Tower Receivers

Secondary Reflectors for Solar Power Tower Receivers

Secondary concentrators are already indispensable in Fresnel collectors but have yet to be implemented in solar tower power plants. In these plants, the temperatures (> 350 °C) and technical conditions (large mirror surface at height of 200 m) are more demanding. The concept developed within the EU project »RAISELIFE« has shown that the implementation of secondary collectors can increase the electrical output and reduce receiver costs compared to a system without secondary concentrators. In addition, Fraunhofer ISE’s material development work on the highly reflective layer shows an improved stability at temperatures above 350°C.

The aim of the »SOLSEC« project is to develop, construct and test a secondary reflector prototype for solar tower receivers.

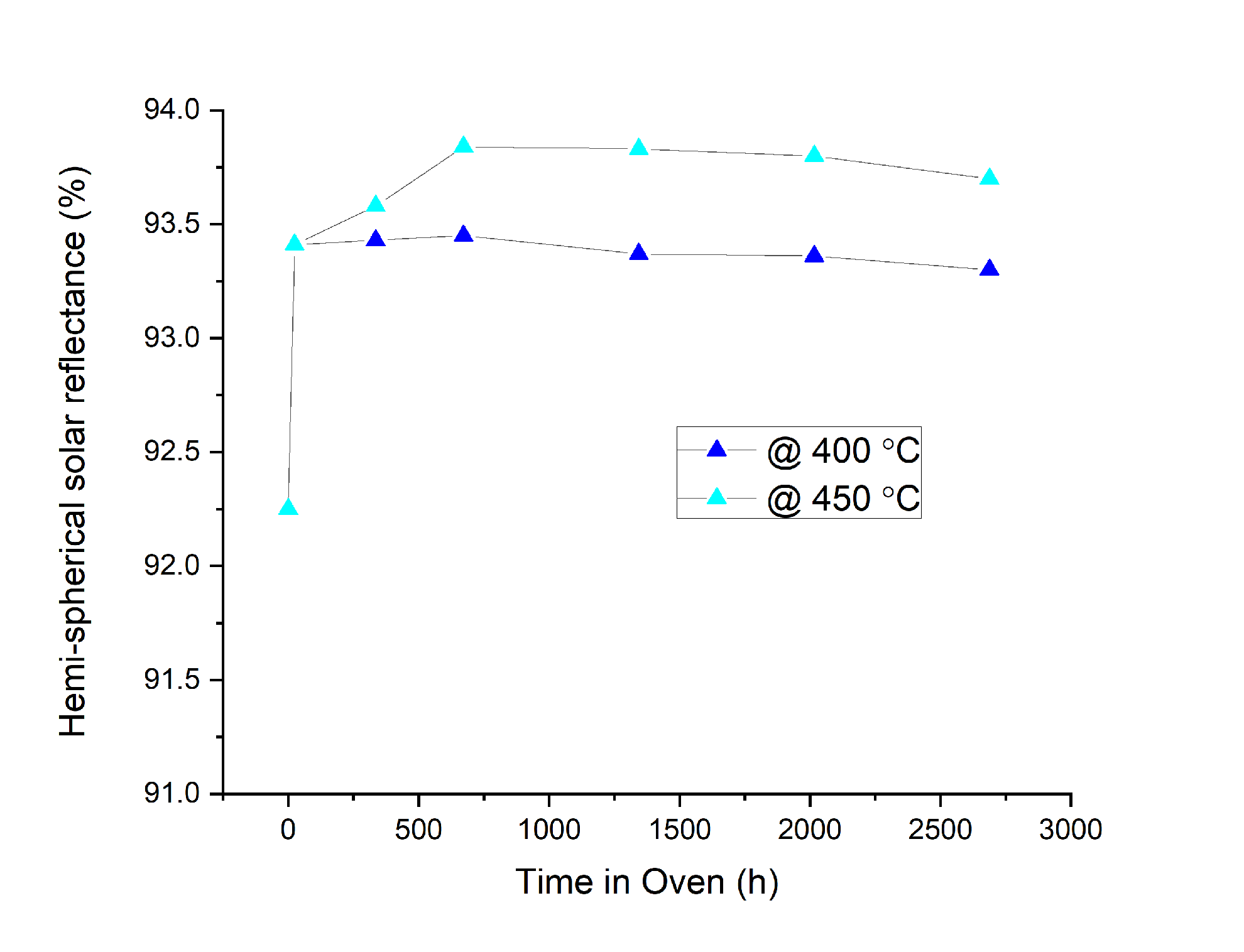

The project has so far developed highly reflective silver-based coatings (Rsol > 93%) that are stable at temperatures above 350 °C for long periods of time (see Figure 1). Preliminary structured prototypes of shaped and mirror polished steel were coated and also furnace tested (see Figure 1).

The prototype will soon be tested in the SYNLIGHT of DLR.

Detailed optical simulations have been performed in the project:

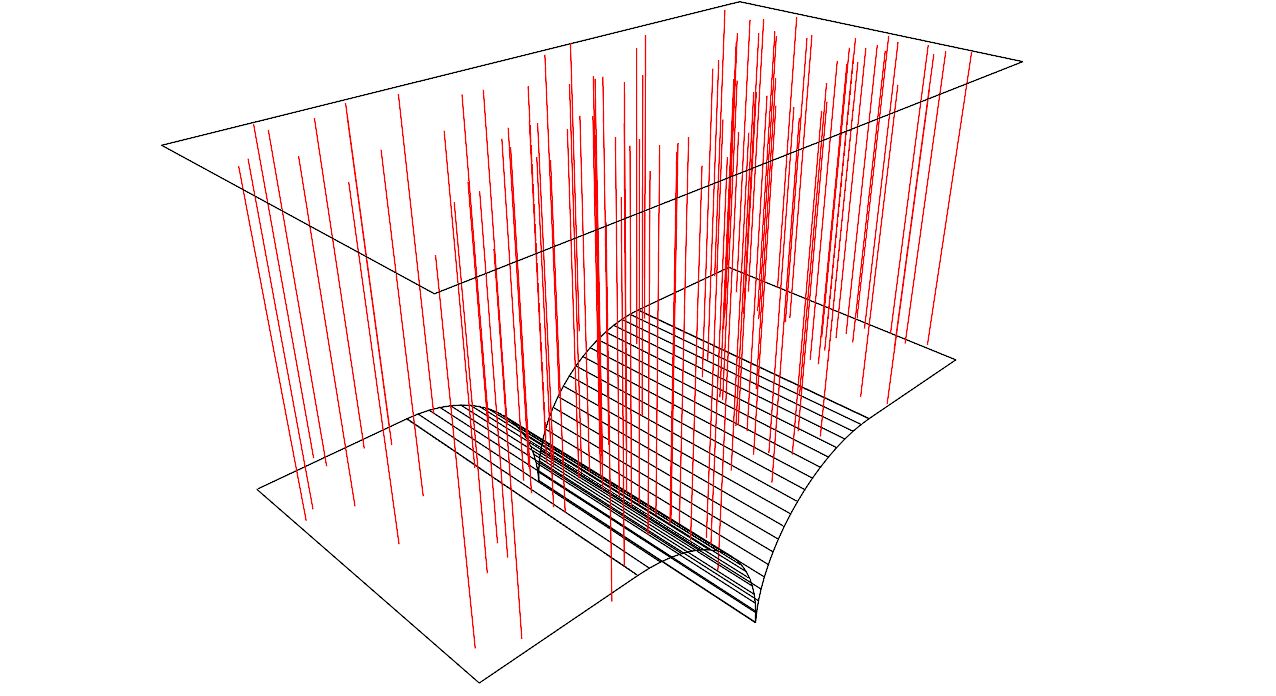

- With our tool Raytrace3D the maximum absorbed radiation on the secondary mirrors and thus the thermal load is determined, depending on their reflectance and the aim point strategy used in the tower power plant.

- Critical aspects such as radiation flux peaks, which can occur in the micro-cavities, are also illuminated (see figure 3). The radiation peaks depend on the reflectance.

- The results of these optical investigations are used for the evaluation of material developments and for the design of the cooling system

With a successful prototype and the know-how gained, the consortium is in a position to present an attractive product portfolio to the industry.

Secondary reflectors can also be used for other types of receivers, such as receivers for chemical reactions requiring high concentrations.

Furthermore, the high temperature stable coatings could be interesting for a broader market (e.g. floodlight manufacturers). Therefore, other potential markets and applications are assessed in the project.