| Duration: | 09/2022 - 08/2027 |

| Contracting Authority/ Sponsors: | Federal Ministry of Education and Research (BMBF), funding code: 03XP0501 Ministerium für Wirtschaft, Innovation, Digitalisierung und Energie des Landes Nordrhein-Westfalen; Ministerium für Kultur und Wissenschaft des Landes Nordrhein-Westfalen |

| Project Partners: | Fraunhofer ICT; Fraunhofer IFAM; Fraunhofer IFF; Fraunhofer IGCV; Fraunhofer IKTS; Fraunhofer IPA; Fraunhofer IPT; Fraunhofer ISI;Fraunhofer ISIT; Fraunhofer-Zentrale with the “Battery Cell Research Production” office. In Münster, Fraunhofer works closely with the University Institute Münster Electrochemical Energy Technology - MEET and the Chair of Production Engineering of E-Mobility Components at RWTH Aachen University. |

| Website: | Fraunhofer FFB |

| Project Focus: | |

FoFeBat3 – Battery Cell Research Production, Sub-Project 3

Energy and Resource-Efficient Battery Cell Production

FoFeBat3 is part of the overall “FoFeBat” project as sub-project 3 and builds on the successes of the first two sub-projects. The aim is to minimize energy and resource consumption in order to enable a more sustainable and economical production of lithium-ion battery cells in Europe. Research has shown that around 80% of energy consumption in cell production is accounted for by the operating costs of clean and dry rooms and electrode production. We are working on innovative approaches that significantly reduce the CO2 footprint. This involves integrating the latest findings into the entire value chain in order to increase quality and reduce costs. Join us on the road to efficient and resource-saving battery cell production!

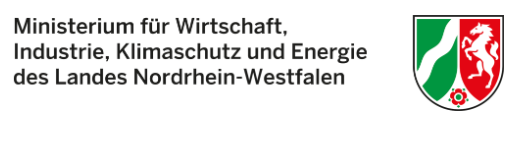

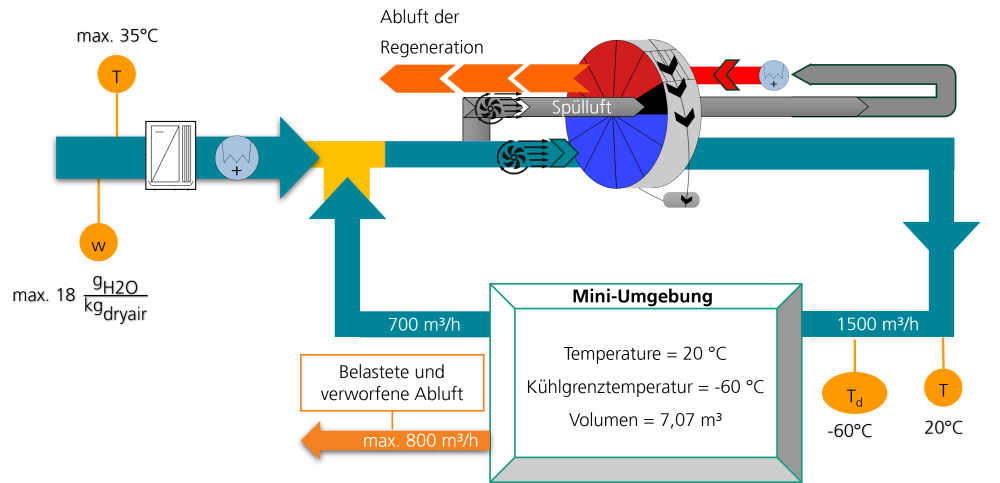

We see great potential for achieving our goal in particular through the individual housing of production steps in battery cell assembly in so-called “mini-environments”. However, each of these “mini-environments” is connected to the consecutive production steps. This concept offers a wide range of optimization options that simultaneously reduce energy requirements and increase production quality, workplace comfort and product safety.

The main challenges of the concept are primarily:

- the achievement of extremely low dew point temperatures of < -60 °C, taking into account the required energy consumption and the health effects on the production personnel,

- a suitable compromise between airtightness of the enclosure and accessibility to the systems

- a high air exchange efficiency under varying thermal and differential pressure conditions and

- partially high particle production rates of the considered processes.

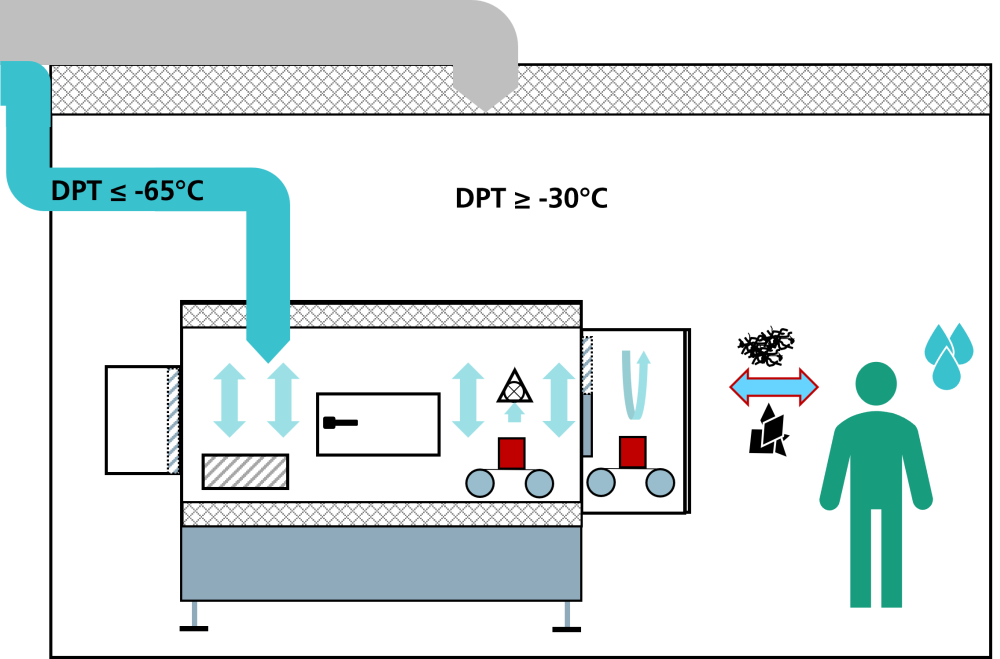

As part of our research work, we are developing a demonstrator test stand as an enclosure for the emulated production steps of battery cell assembly. In addition to the enclosure itself, this also includes the air conditioning system and installations for suitable air routing.

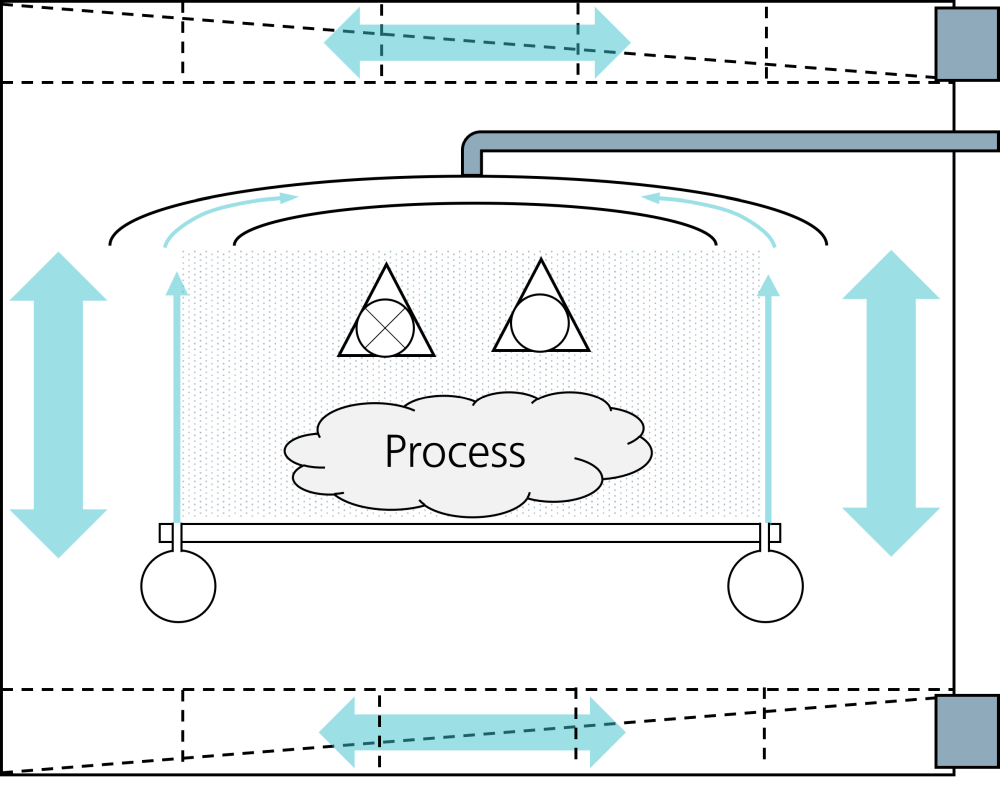

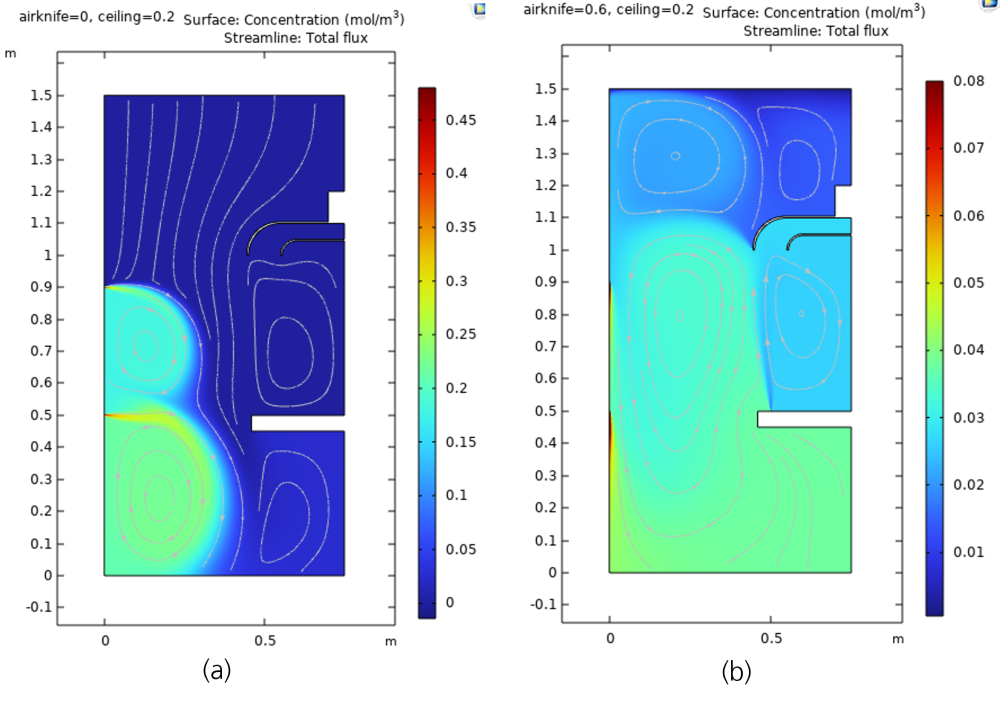

The development is accompanied by simulation studies on the air flows in the enclosure and object-oriented simulations of the air conditioning for year-round operation. For this purpose, we use COMSOL Multiphysics(R) for the CFD flow simulations and Dymola Modelica with TLK's TIL suite for the object-oriented simulation.

Later in the project, various production steps will be emulated and evaluated metrologically by varying the test stand parameters. Studies on the thermal comfort of employees are also planned for this project phase.

Initial work results in the project include:

- A 3D design of the test stand, which is coordinated with various companies.

- The simulation of different air conditioning processes using adsorptive drying.

- The design of the required air conditioning.

- Flow analyses for promising configurations of supply and exhaust air diffusers in the enclosure.

- Development of a measurement concept for the metrological recording of various flow situations and disturbance variables.

Links

- Der energie- und ressourceneffizienten Batteriezellfertigung ein Stück näher: Das Teilprojekt 3 des »FoFeBat«-Projekts startet (ffb.fraunhofer.de)

- QueEn: »Quality-oriented and energy-reduced plant technology for LIB- and NextGen-production in mini-environments« (ffb.fraunhofer.de)

- Mini-Environments In Lithium-Ion Battery Cell Production: A Survey On Current State, Challenges And Trends Plocher et al. (publica-rest.fraunhofer.de)