| Duration: | 10/2020 - 01/2024 |

| Contracting Authority/ Sponsors: | BMBF-Kompetenzcluster Batterienutzungskonzepte (BattNutzung); Querschnittsinitiative Batterie-Lebenszyklus; Projektträger Jülich; Förderkennzeichen: 03XP0312A-B |

| Project Partners: | RWTH Aachen University; Institut für Stromrichtertechnik und Elektrische Antriebe (ISEA); Lehrstuhl für Alterungsprozesse und Lebensdauerprognose von Batterien (ALB) |

| Website: | OrtOptZelle |

| Project Focus: |

OrtOptZelle – Position-Dependent Compression of Battery Pouch Cells for Lifetime Optimization

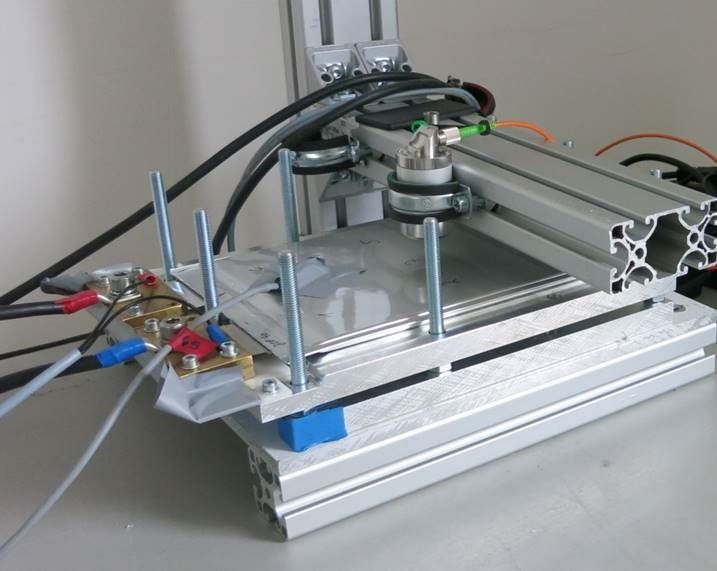

During charging and discharging, lithium-ion batteries undergo both reversible and irreversible thickness expansion. This can lead to a substantial mechanical load inside the battery cell causing delamination or short-cut of the electrodes. The increase in the battery thickness can also cause pressure on the neighboring battery cells in case of stapled module. These mechanical loads have a direct impact on the service life and reliability of the battery cells and can lead to safety issues. The central goal of the project OrtOptZelle is to identify the area distribution of the changes in volume and pressure on the cell. It involves the precisely measurement of these volume changes during the charging and discharging processes, generating a spatially resolved map and then correlating it with the aging of the cells. Aiming the increase in their service life locally distinguished external compression will be applied on the cells during operation. The findings of this project should contribute in particular to the improvement of the battery cells during their operation regarding the aging process, reliability and safety as well as a hint for a appropriate module design.

The OrtOptZelle collaborative project aims to increase the service life of lithium-ion batteries during their operational phase by optimizing mechanical pressure distribution. To this end, the spatial resolution of volume changes induced by charging and discharging will be determined using large pouch cells and the inhomogeneity of these changes will be mapped. A complete picture of the inhomogeneity of large-scale pouch cells will then be established together with spatially resolved reaction heat and current density distributions in combination with post-mortem analyses and computer tomographic images. The combination with a controlled cell aging process will provide insight into the influence inhomogeneities have on aging. This, in turn, will make a significant contribution to the understanding of aging processes in lithium-ion batteries, which falls under subject area B of the Federal Ministry of Education and Research (BMBF) Competence Cluster dedicated to battery usage concepts and focused on aging and service life prognoses. This understanding will subsequently be used to optimize mechanical pressure distribution from the outside, ultimately improving battery cell service life. These investigations serve the overarching mission of the Competence Cluster with regard to the analysis of scalability with a view to large-scale battery cells and large battery packs.

Another project goal is to validate methods for the rapid characterization of inhomogeneities in large pouch cells, ultimately supporting the BMBF’s “Battery research factory” (“Forschungsfabrik Batterie”) umbrella concept. The concept allows for the methods to be used both for quality assurance and for optimizing the geometry of large-scale pouch cells. They can also aid in accelerating the optimization of process or material parameters with regard to shape, layering and electrode components (binders, active materials). Moreover, the results of the project will allow for the optimization of battery module pressure conditions, leading to significant increases in the service lives of large-scale pouch cells during their operational phase. Increasing the service life of a battery cell has a significant impact on the battery’s overall sustainability, which supports the core idea of the BMBF’s “Battery research factory” umbrella concept and the Competence Cluster focused on battery usage concepts.