| Duration: | 07/2023 - 06/2026 |

| Contracting Authority/ Sponsors: | Federal Ministry of Economic Affairs and Climate Action (BMWK) |

| Project Partners: | Kraftblock GmbH; Comet Schleiftechnik GmbH |

| Project Focus: |

LuftBlock

Further Development and Testing of a High-Temperature Heat Storage with Innovative Packed-Bed Technology and Air as a Heat Transfer Medium in the Ceramics Industry

High-temperature heat storage systems can make a significant contribution to the decarbonization of industrial processes. They enable the efficient use of waste heat and at the same time the integration of electrical heating elements to replace fossil fuels. Heat storage systems enable a flexible energy supply for processes by decoupling the use of thermal energy from the generation of energy. This is economically interesting, as waste heat that might otherwise have been lost can be used at a later point in time, thus reducing energy consumption. In addition, a heat storage system allows electricity to be purchased at a time adapted to a variable market price.

In the German ceramics industry, the annual energy requirement is around 10 TWh, which is currently largely covered by burning natural gas in the kilns. The development and provision of a cost-effective and robust high-temperature heat storage system for the ceramics industry therefore not only offers the opportunity to significantly reduce its CO2 emissions, but also to lower operating costs and reduce dependency and risks in energy supply.

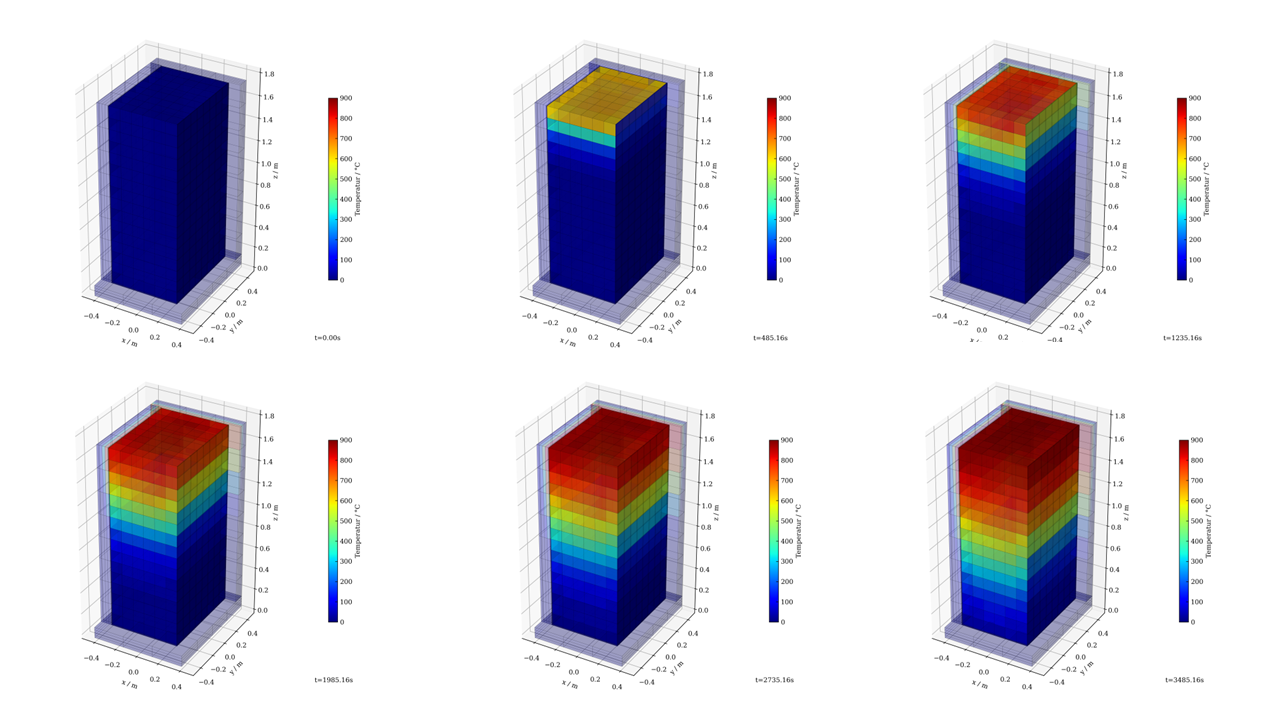

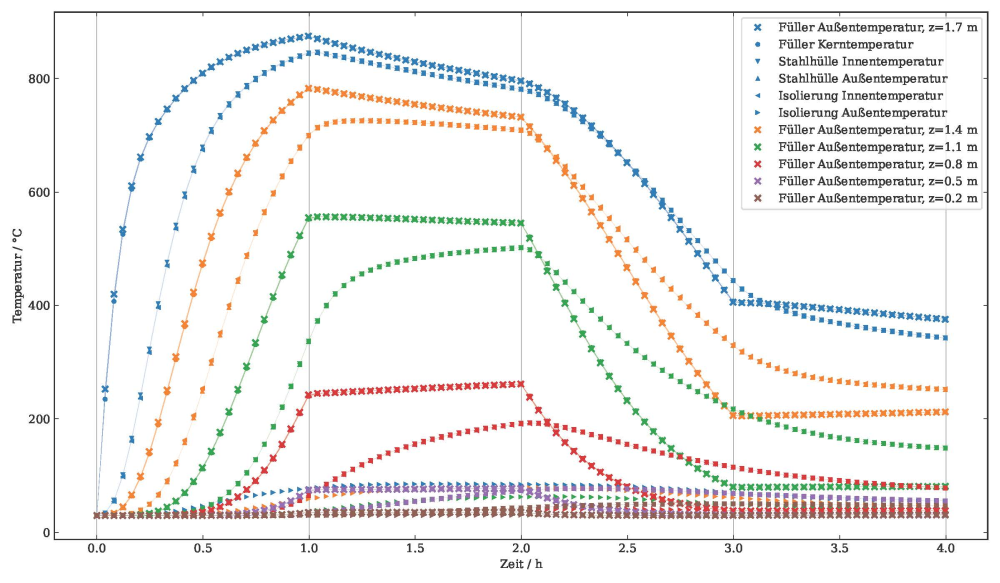

In the “LuftBlock” research project, Kraftblock's innovative high-temperature heat storage solution is being further developed and demonstrated on an industrial scale at Comet Schleiftechnik. The project focuses on the thermo-mechanical simulation as well as the further development and testing of the storage tank with innovative packed-bed technology and air as a heat transfer medium for storage temperatures of up to 900 °C. The overarching aim of the project is to overcome obstacles that have so far made the widespread commercial introduction of packed-bed storage tanks difficult or necessitated costly design solutions and oversizing.

Aparticular aspect of the developed solution is the direct use of exhaust air from industrial processes that may be contaminated with dust or condensates. The direct use of this exhaust air can reduce costs and increase the potential for recovered energy, as losses through heat exchangers are avoided. However, deposits can build up over time and impair the performance of the storage tank. The various deposition processes are being analyzed in order to develop solutions for maintaining a high performance of the storage tank in the long term.

The mechanical behavior of the packed-bed tank is also being investigated. The plastic deformation of the walls in packed-bed storage tanks as a result of the thermal expansion of the storage material under cyclical thermal loading is not yet fully understood. This has often stood in the way of the widespread commercial introduction of packed-bed storage systems or has led to various cost-driving design solutions and oversizing to counteract the effect. As a result, the realization of packed-bed heat storage systems has so far been less attractive.

For technical and economic evaluation, small-scale test stands are being set up in the laboratories at Fraunhofer ISE and at Kraftblock and prototype subsystems are being experimentally characterized before an industrial-scale storage system is implemented at Comet and integrated into production.