Jahr

Year | Titel/Autor:in

Title/Author | Publikationstyp

Publication Type |

|---|

| 2023 |

Anpassung von beschleunigten Alterungstests an die spezifischen Anforderungen und Bedingungen aufkommender Photovoltaik-Anwendungsarten

Weiß, Karl-Anders; Markert, Jochen; Hädrich, Birgit Ingrid; Gebhardt, Paul; Klimm, Elisabeth |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Benefits of pairing floating solar photovoltaics with hydropower reservoirs in Europe

Kakoulaki, Georgia; Gonzalez Sanchez , Rocio; Gracia Amillo, Ana Maria; Szabo, Sandor; Felice, Matteo de; Farinosi, Fabio; Felice, Luca de; Bisselink, Berny; Seliger, Roman; Kougias, Ioannis; Jaeger-Waldau, Arnulf |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Photovoltaic Noise Barriers as Energy Generating Infrastructure: Functional Overview about Five Solutions

Forster, Jacob; Tsutskiridze, Giorgi; Kohlhauer, Reinhard; Huyeng, Jonas; Herr, Cornelius; Basler, Felix; Neuhaus, Dirk Holger; Heinrich, Martin; Rendler, Li Carlos |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Modeling of thin-film interference filters on structured substrates: Microfacet-based BSDF versus ray tracing

Wessels, Andreas; Christen, Leonard; Callies, Adrian; Kroyer, Thomas; Höhn, Oliver; Bläsi, Benedikt |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

PV at Multi-Terawatt Scale: Waiting is not an Option

Philipps, Simon |

Vortrag

Presentation

|

| 2023 |

F&E Entwicklungen vom Si-Material bis zum Modul: Nachhaltig und hochproduktiv

Wolf, Andreas |

Vortrag

Presentation

|

| 2023 |

Thermomechanische Bewertung von BIPV-Modulen mittels FEM Simulation

Beinert, Andreas; Mahfoudi, Achour; Ensslen, Frank; Erban, Christof |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Energiesicherheit und klimaneutrale Energiesysteme

Henning, Hans-Martin |

Vortrag

Presentation

|

| 2023 |

Auf dem Weg in eine klimaneutrale Energieversorgung - Transformationspfade für die deutsche Energiewende

Henning, Hans-Martin |

Vortrag

Presentation

|

| 2023 |

PV-Produktion in Europa - Aktueller Status

Bett, Andreas W.; Rentsch, Jochen; Preu, Ralf |

Konferenzbeitrag

Conference Paper

|

| 2023 |

MorphoColor® PV Modules: From Modeling/Design to Demo Installations

Bläsi, Benedikt; Wessels, Andreas; Christen, Leonard; Kroyer, Thomas; Höhn, Oliver; Mattenheimer, Martin; Kuhn, Tilmann; Reinwand, Dirk; Heinrich, Martin; Neuhaus, Holger |

Vortrag

Presentation

|

| 2023 |

Evaluation of the German agrivoltaics innovation tender 2022 and overview about the agrivoltaics development in Germany

Pump, Carl; Trommsdorff, Maximilian; Beckmann, Volker; Bretzel, Tamara; Özdemir, Özal Emre; Bieber, Lisa-Marie |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Smart mobile vaccination pickup for sustainable improvement of medical care and smart pandemic control in Southern Africa

Stortz, Felix; Went, Joachim; Koschikowski, Joachim; Maruf, Md Nasimul Islam; Schäfer, Lothar; Neumann, Frank; Lotz, Bryan; Beckett, Marc; Hamann, Maike |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Building-Integrated Photovoltaic (BIPV) products and systems: A review of energy-related behavior

Martín-Chivelet, Nuria; Kapsis, Konstantinos; Wilson, Helen Rose; Delisle, Veronique; Yang, Rebecca; Olivieri, Lorenzo; Polo, Jesús; Eisenlohr, Johannes; Roy, Benjamin; Maturi, Laura; Otnes, Gaute; Dallapiccola, Mattia; Upalakshi Wijeratne, W.M. Pabasara |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Rainwater Management in Agrivoltaic Systems - Research and Development Potential

Rößner, Johanna-Viktoria |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Technical Aspects for Road Integrated Photovoltaics Towards a More Sustainable Mobility Sector

Huyeng, Jonas; Forster, Jacob; Basler, Felix; Romer, Pascal; Beinert, Andreas; Schill, Christian; Heinrich, Martin; Neuhaus, Holger; Wirth, Harry |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Economic evaluation of agrivoltaics in German apple cultivation

Hopf, Michaela; Trommsdorff, Maximilian; Wydra-Dürr, Kerstin |

Vortrag

Presentation

|

| 2022 |

Progress and Challenges of Crop Production and Electricity Generation in Agrivoltaic Systems Using Semi-transparent Photovoltaic Technology

Gorjian, S.; Bousi, Erion; Özdemir, Özal Emre; Trommsdorff, Maximilian; Manoj Kumar, N.; Anand, A.; Kant, K.; Chopra, S.S. |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

An Assessment of Light Availability and Distribution Inside of a Photovoltaic Greenhouse

Özdemir, Özal Emre; Berwind, Matthew |

Vortrag

Presentation

|

| 2022 |

Fully Black and Reliable PV Modules with a Cost-Effective Inkjet Coating of Cell Strings

Schiller, Christian; Hoffmann, Stephan; Jahn, Mike; De Rose, Angela; Heinrich, Martin |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Investigation of decoupling of thermal and electrical performance of semi-transparent photovoltaic windows based on the external quantum efficiency

Zhou, Hao; Peng, Jinqing; Wilson, Helen Rose; Wang, Meng; Jonsson, Jacob; Ma, Tao; Wu, Ben; Wu, Bochao; Fu, Ganhua |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Building Product Ontology: Core Ontology for Linked Building Product Data

Wagner, A.; Sprenger, Wendelin; Maurer, Christoph; Kuhn, Tilmann E.; Rüppel, U. |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Modeling the optical properties of Morpho-inspired thin-film interference filters on structured surfaces

Wessels, Andreas; Callies, Adrian; Bläsi, Benedikt; Kroyer, Thomas; Höhn, Oliver |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Wirtschaftlichkeitsbetrachtung der Agri-PV im Apfelanbau

Hopf, Michaela; Trommsdorff, Maximilian; Wydra, Kerstin |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Challenges for Agrivoltaics in the International Context - An Analytical Hierarchy Process Survey

Vorast, Maximilian |

Vortrag

Presentation

|

| 2022 |

Effect of feature size on the reflective behaviour of the MorphoColorTM concept

Callies, Adrian; Wessels, Andreas; Bett, Andreas; Bläsi, Benedikt; Höhn, Oliver |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Development and Analysis of an Off-grid Solar Food Processing System in Kenya

Morgenstern, Alexander; Subasi, Dilara Maria; Pfanner, Norbert; Reiners, Nils; Stortz, Felix; Wüllner, Johannes; Maruf, Md Nasimul Islam |

Konferenzbeitrag

Conference Paper

|

| 2022 |

PV Roofing for High Ranking Road Networks: Technical Feasibility and Yield Estimation

Ebner, Rita; Mayr, Christoph; Rennhofer, Marcus; Berger, Karl A.; Heinrich, Martin; Basler, Felix; Beinert, Andreas; Fehringer, Markus; Huyeng, Jonas; Beck, Tobias; Haider, Manfred; Prammer, Dominik; Vorwagner, Alois |

Konferenzbeitrag

Conference Paper

|

| 2022 |

APV-Bot Demonstrator

Fahmy, Karim Mohamed Tamer Mahmoud |

Vortrag

Presentation

|

| 2022 |

Technical Aspects for Road Integrated Photovoltaics Towards a More Sustainable Mobility Sector

Huyeng, Jonas; Forster, Jacob; Basler, Felix; Romer, Pascal; Beinert, Andreas; Schill, Christian; Heinrich, Martin; Neuhaus, Holger; Wirth, Harry |

Poster

|

| 2022 |

Softwareunabhängig-verlustfreie Projektdatenumgebung und föderal-selbstbeschreibende parametrische Modellierung multifunktionaler Bauprodukte auf Basis des Semantic Web mit Fokus auf die Gebäudehülle. Schlussbericht

Maurer, Christoph; Rist, Tim; Kuhn, Tilmann; Shi, Meiling; Huyeng, Tim-Jonathan; Hoffmann, André; Thiele, Christian-Dominik; Rüppel, Uwe; Sprenger, Wendelin |

Bericht

Report

|

| 2021 |

Potential of Agrivoltaics to Contribute to Socio-Economic Sustainability: A Case Study in Maharashtra / India

Trommsdorff, Maximilian; Vorast, Maximilian; Durga, N.; Padwardhan, S. |

Konferenzbeitrag

Conference Paper

|

| 2021 |

Proposal for a Safety Qualification Program for Vehicle-Integrated PV Modules

Markert, Jochen; Kutter, Christoph; Newman, B.; Gebhardt, Paul; Heinrich, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

The MorphoColor Concept for Colored Photovoltaic Modules

Bläsi, Benedikt; Kroyer, Thomas; Kuhn, Tilmann E.; Höhn, Oliver |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Potenziale der Integrierten Photovoltaik in Deutschland

Wirth, Harry; Eggers, Jan-Bleicke; Trommsdorff, Maximilian; Neuhaus, Dirk Holger; Heinrich, Martin; Wieland, S.; Schill, Christian |

Konferenzbeitrag

Conference Paper

|

| 2021 |

Aktueller Stand der Forschung/Entwicklung für Gebäudeintegrierte PV

Kuhn, Tilmann |

Vortrag

Presentation

|

| 2021 |

Untersuchung verschattungsoptimierter Halbzellenmodule mit einlaminierter Leistungselektronik für das MPP-Tracking auf Substring-Ebene

Armbruster, Cornelius; Kutter, Christoph; Schmid, A.; Tummalieh, Ammar; Rouffaud, Gilles; Basler, Felix; Wille-Haußmann, Bernhard; Famulla, J.; Schüler, Marc Andre; Oyebanji, U.O. |

Konferenzbeitrag

Conference Paper

|

| 2021 |

Durchführbarkeitsstudie zur Ermittlung möglicher Forschung- und Demonstrationsfelder für Agri-Photovoltaik in Baden-Württemberg

Hörnle, Oliver; Riedelsheimer, Julia; Trommsdorff, Max; Keinath, Tobias; Binder, Florian; Weinmann, Ernst; Klodt, Frederik; Zikeli, Sabine; Pataczek, Lisa; Rueß, Franz; Köppler, Kirsten; Glas, Michael; Mayr, Ulrich; Frey, Michael; Kromrey, Volker; Vedel, Dimitri; Klein, Alexandra |

Studie

Study

|

| 2021 |

Opening Address EU-PVSEC 2021

Bett, Andreas W. |

Vortrag

Presentation

|

| 2021 |

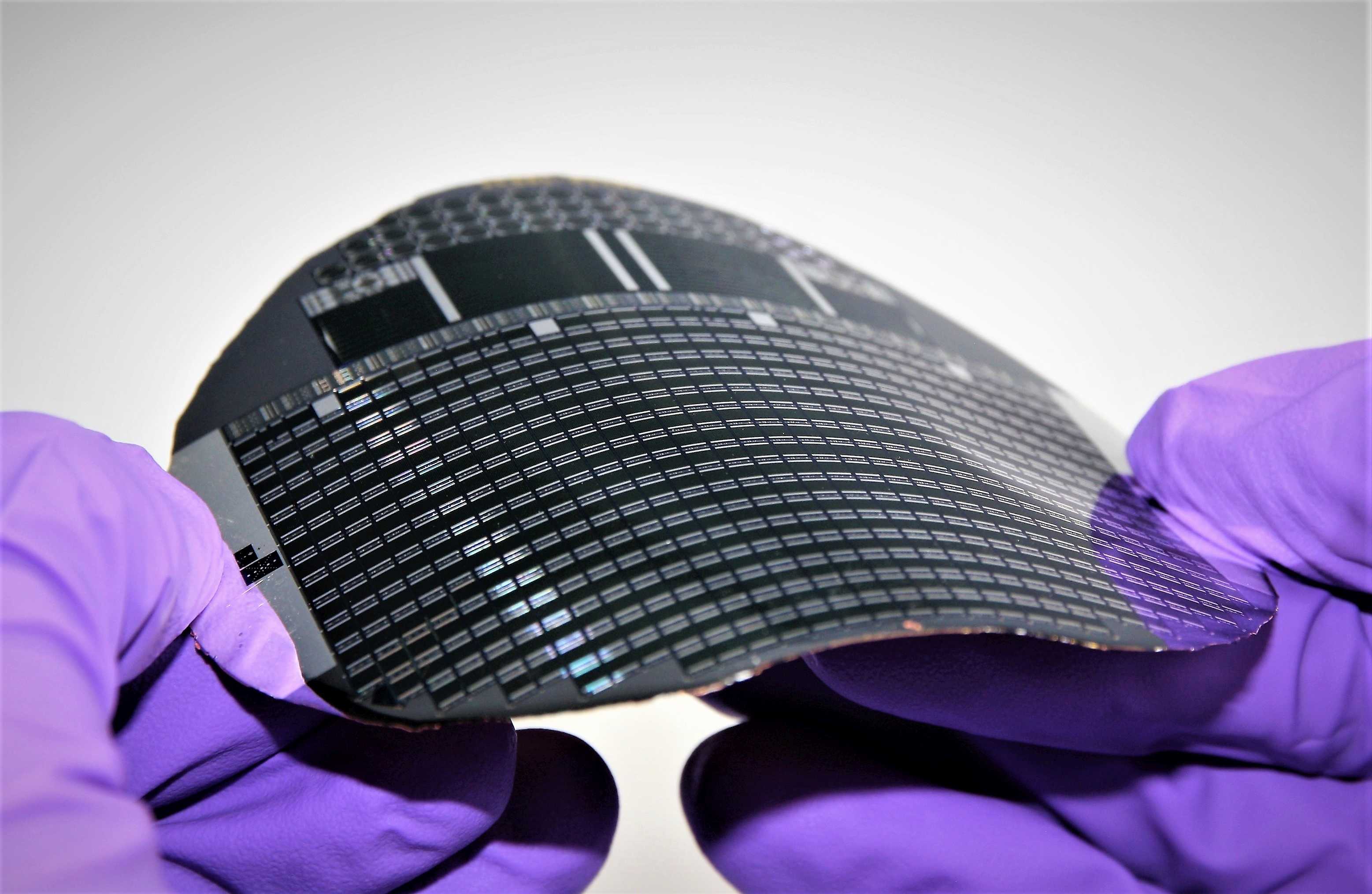

Energy Yield Simulation of 3D Curved VIPV Modules

Neven-du Mont, Sebastian; Alharthi, Hashem; Kutter, Christoph; Neuhaus, Holger; Heinrich, Martin |

Konferenzbeitrag

Conference Paper

|

| 2021 |

BauwerkIntegrierte PV (BIPV) Stand der Forschung & Entwicklung

Kuhn, Tilmann |

Vortrag

Presentation

|

| 2021 |

Materialinnovationen für die Solarenergie

Bett, Andreas W. |

Vortrag

Presentation

|

| 2021 |

Legal Framework of Agrivoltaics in Germany

Vollprecht, Jens; Trommsdorff, Maximilian; Hermann, C. |

Konferenzbeitrag

Conference Paper

|

| 2021 |

Review of Technological Design Options for Building Integrated Photovoltaics (BIPV)

Kuhn, Tilmann E.; Erban, C.; Heinrich, Martin; Eisenlohr, Johannes; Ensslen, Frank; Neuhaus, Dirk Holger |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

The MorphoColor Concept for Colored Photovoltaic Modules and Solar Thermal Collectors

Bläsi, Benedikt; Wessels, Andreas; Callies, Adrian; Eisenlohr, Johannes; Ensslen, Frank; Kuhn, Tilmann; Kroyer, Thomas; Höhn, Oliver |

Vortrag

Presentation

|

| 2021 |

Integrating PV: PV where People Live, Work and Farm

Wirth, Harry |

Vortrag

Presentation

|

| 2021 |

Solarstrom als Pfeiler des Energiewandels

Bett, Andreas W. |

Vortrag

Presentation

|

| 2021 |

Economic analysis of agrivoltaics in orchard farming in Germany

Hopf, Michaela; Trommsdorff, Maximilian; Wydra, Kerstin |

Meeting Abstract

|

| 2021 |

Production of Photovoltaics in Europe. Opportunities and Challenges

Bett, Andreas W. |

Vortrag

Presentation

|

| 2021 |

PV Manufacturing in Europe. Statements

Bett, Andreas W. |

Vortrag

Presentation

|

| 2021 |

Evaluating BIPV Modules with Respect to Textural Appearance, Glare, Colour and Electricity Yield

Wilson, Helen Rose; Bueno Unzeta, Bruno; Eisenlohr, Johannes; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2020 |

Implementation of agrophotovoltaics. Techno-economic analysis of the price-performance ratio and its policy implications

Schindele, Stephan; Trommsdorff, Maximilian; Schlaak, A.; Obergfell, Tabea; Bopp, Georg; Reise, Christian; Braun, Christian; Weselek, A.; Bauerle, A.; Högy, P.; Goetzberger, Adolf; Weber, Eicke R. |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

GIS-basierte Potenzialanalyse für Agrophotovoltaik - Eine Fallstudie für die Region Bodensee-Oberschwaben

Hauger, Salome; Schindele, Stephan; Winkelhausen, Harald; Gimbel, Edgar; Wolf, Maritta; Jung, Martina; Beuerle, Rainer |

Poster

|

| 2020 |

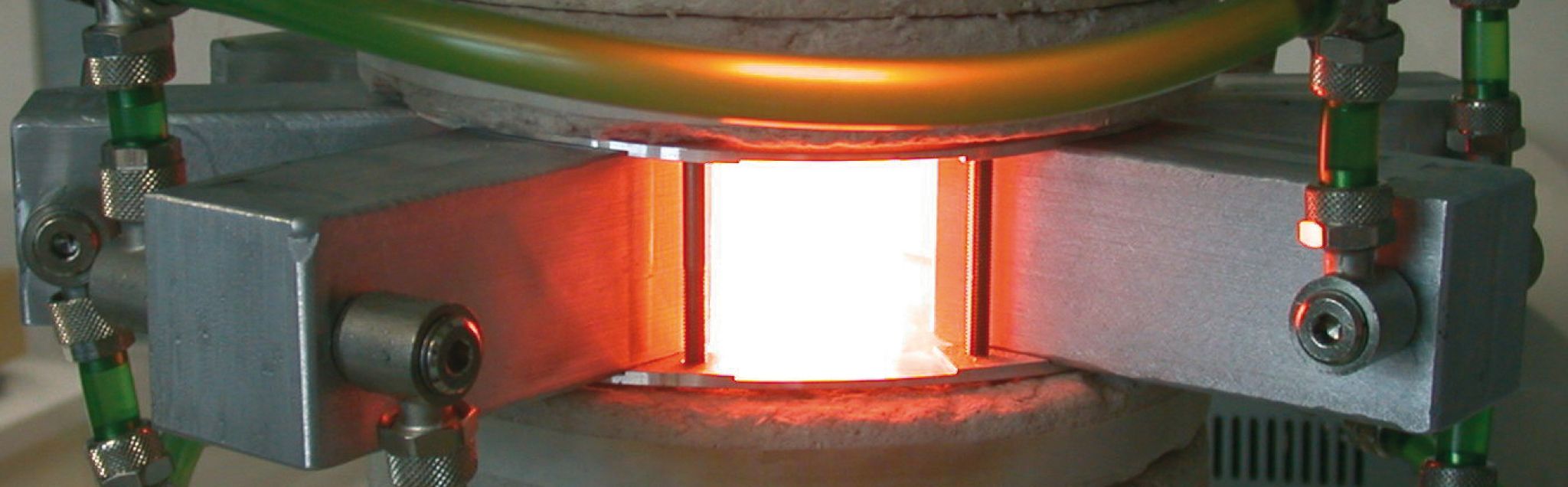

Spray Pyrolysis - a Versatile Technique for Thin Film Deposition in PV

Bartsch, Jonas; Heitmann, Ulrike; Jakob, Leonie; Mahmoud Algazzar, R.; Tutsch, Leonard; Hermann, R.; Kluska, Sven; Bivour, Martin; Bläsi, Benedikt; Hauser, Hubert; Janz, Stefan; Glatthaar, Markus |

Konferenzbeitrag

Conference Paper

|

| 2020 |

Colored Modules for Integrated PV: From the MorphoColor-Concept to High Efficiency Prototypes

Bläsi, Benedikt |

Vortrag

Presentation

|

| 2020 |

Bridging two Worlds - Standards for BIPV

Wilson, Helen Rose |

Vortrag

Presentation

|

| 2019 |

Compilation and Analysis of User Needs for BIPV and its Functions

Boddaert, Simon; Benson, Jessica; Bonomo, Pierluigi; Delisle, Véronique; Erban, Christof; Fedorova, Anna; Frontini, Francesco; Inoue, Seiji; Ishii, Hisashi; Kapsis, Konstantinos; Kim, Jun-Tae; Kovacs, Peter; Machado, Maider; Chivelet, Nuria Martín; Medina, Eduardo Román; Schneider, Astrid; Wilson, Helen Rose |

Bericht

Report

|

| 2019 |

Novel, Semi-transparent BIPV-Modules with New Design Features

Eisenlohr, Johannes; Ensslen, Frank; Heinrich, Martin; Schönrock, L.; Görich, K.; Tauchert, P.; Tersluisen, A.; Jäger, F.; Aßländer, O.; Höhne, J.; Stark, T.; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2019 |

Analysis of requirements, specifications and regulation of BIPV

Berger, Karl; Boddaert, Simon; Buono, Matteo del; Fedorova, Anna; Frontini, Francesco; Inoue, Seiji; Ishii, Hisashi; Kapsis, Konstantinos; Kim, Jun-Tae; Kovacs, Peter; Machado, Maider; Chivelet, Nuria Martín; Schneider, Astrid; Wilson, Helen Rose |

Bericht

Report

|

| 2019 |

Neuartige, teiltransparente BIPV-Module mit erhöhtem Gestaltungsspielraum

Kuhn, Tilmann; Tersluisen, A.; Eisenlohr, Johannes; Eggers, Jan-Bleicke; Mondon, Andrew; Ensslen, Frank; Schönrock, L.; Klages, C.; Görich, K.; Georgi-Tomas, A.; Jäger, F.; Aßländer, O.; Höhne, J.; Stark, T. |

Konferenzbeitrag

Conference Paper

|

| 2019 |

Confidential Feedback Workshops as a Method to Foster Innovation. Deliverable B.3

Maurer, Christoph |

Bericht

Report

|

| 2019 |

Rule-Based Views and Linked Building Data for Efficient Planning Processes

Maurer, Christoph; Wagner, Anna; Wengzinek, J.; Rüppel, U.; Sprenger, Wendelin; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2019 |

Aktive solare Gebäudehülle zur dezentralen Energieerzeugung in Gebäuden

Kuhn, Tilmann |

Vortrag

Presentation

|

| 2019 |

Regulatory aspects of BIPV

Wilson, Helen Rose; Frontini, Francesco; Chivelet, N.M. |

Vortrag

Presentation

|

| 2019 |

Rule-Based Views and Linked Building Data for Efficient Planning Processes

Maurer, Christoph; Wagner, Anna; Wengzinek, J.; Rüppel, U.; Sprenger, Wendelin; Kuhn, Tilmann |

Vortrag

Presentation

|

| 2018 |

A Systematic Workflow for Retrofitting Office Façades with Large Window-to-Wall Ratios Based on Automatic Control and Building Simulations

Bueno Unzeta, Bruno; Cejudo Lopez, José Manuel; Katsifaraki, A.; Wilson, Helen Rose |

Zeitschriftenaufsatz

Journal Article

|

| 2018 |

Building-integrated Solar Thermal Systems in the Architectural Design Stage

Maurer, Christoph; Kuhn, Tilmann E. |

Aufsatz in Buch

Book Article

|

| 2018 |

Report on Barriers for New Solar Envelope Systems. Deliverable B.1

Hubschneider, Carolin; Maurer, C.; Taveres-Cachat, Ellika; Eisenlohr, J.; Hollick, John; Lemarchand, Philippe; Garay, Roberto; Loonen, Roel; Aagesen, Vickie |

Bericht

Report

|

| 2018 |

Mosaic Module Concept for Cost-Efficient and Aesthetic BIPV Modules

Mittag, Max; Ebert, Matthieu; Wilson, Helen Rose; Fellmeth, Tobias |

Konferenzbeitrag

Conference Paper

|

| 2018 |

Detailed Yield Analysis and Optimisation of BIPV Systems by Simulation

Eisenlohr, Johannes |

Zeitschriftenaufsatz

Journal Article

|

| 2018 |

International definitions of "BIPV"

Berger, Karl; Cueli, Ana Belén; Boddaert, Simon; Buono, Matteo del; Delisle, Véronique; Fedorova, Anna; Frontini, Francesco; Hendrick, Patrick; Inoue, Seiji; Ishii, Hisashi; Kapsis, Costa; Kim, Jun-Tae; Kovacs, Peter; Chivelet, Nuria Martín; Maturi, Laura; Machado, Maider; Schneider, Astrid; Wilson, Helen Rose |

Bericht

Report

|

| 2018 |

Construct-PV: Constructing Buildings with Customizable-size PV Modules Integrated in the Opaque Part of the Building Skin

Wilson, Helen Rose; Fath, K. |

Vortrag

Presentation

|

| 2018 |

Using Digitalization for More Reliable and Less Expensive Building Performance Analysis

Maurer, Christoph; Wilson, Helen Rose; Curcija, D.C.; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2018 |

Building-Integrated Photovoltaics - Combining Colour and Efficient Power Generation

Wilson, Helen Rose |

Vortrag

Presentation

|

| 2018 |

Architektonisch anspruchsvolle, fassadenintegrierte Photovoltaik am ZÜBLIN-Gebäude Z3

Fath, K.; Eisenlohr, Johannes; Wilson, Helen Rose; Kuhn, Tilmann |

Vortrag

Presentation

|

| 2018 |

Highly Efficient Coloured BIPV Modules with Anti-glare Properties

Eisenlohr, Johannes; Ferrara, Claudio; Bläsi, Benedikt; Kroyer, Thomas; Höhn, Oliver; Heinrich, Martin; Eitner, Ulrich; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2018 |

Flexible Filtering of Heterogeneous Data Using the Example of the Design and Simulation of Building Integrated Photovoltaics

Eisenlohr, Johannes; Eller, C.; Rüppel, U.; Leifgen, C.; Boudhaim, M.; Maurer, Christoph; Sprenger, Wendelin; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2017 |

IFC-based electricity simulation of a complex BIPV façade

Eisenlohr, Johannes; Wilson, Helen Rose; Kuhn, Tilmann |

Vortrag

Presentation

|

| 2017 |

Machine code functions in BIM for cost-effective high-quality buildings

Maurer, Christoph; Sprenger, Wendelin; Franz, Sebastian; Lodewijks, J.; Rüppel, U.; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2017 |

Machine-code functions in BIM for cost-effective high-quality buildings

Maurer, Christoph; Sprenger, Wendelin; Franz, Sebastian; Boudhaim, M.; Lodewijks, J.; Rüppel, U.; Kuhn, Tilmann E. |

Zeitschriftenaufsatz

Journal Article

|

| 2017 |

Modelling of active solar building envelopes for cost-effective evaluation

Maurer, Christoph; Kuhn, Tilmann E. |

Zeitschriftenaufsatz

Journal Article

|

| 2017 |

BIPV market-size and technologies - today and future

Ferrara, Claudio |

Vortrag

Presentation

|

| 2017 |

Building-integrated photovoltaics (BIPV)

Ferrara, Claudio; Wilson, Helen Rose; Sprenger, Wendelin |

Aufsatz in Buch

Book Article

|

| 2017 |

Application of PV modules for BIPV - new challenges for performance and durability assessment and the European response

Wilson, Helen Rose |

Vortrag

Presentation

|

| 2017 |

Aufbau, Betrieb und simulationsgestützte Analyse einer hinterlüfteten BIPV-Fassade mit MWT-TPedge-Modulen

Wilson, Helen Rose; Eisenlohr, Johannes; Armbruster, Alfons; Spribille, Alma; Mittag, Max; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2017 |

Modelling of active building envelopes for cost-effective evaluation

Maurer, Christoph; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2017 |

Photovoltaik in der Gebäudehülle - Normierung und Prüfung

Rehde, F.; Wilson, Helen Rose |

Vortrag

Presentation

|

| 2017 |

Detailed modelling of building-integrated photovoltaics - from component and environmental data to the system output

Eisenlohr, Johannes; Wilson, Helen Rose; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|

| 2016 |

Gebäudehülle und Energie: Aktive und passive Systeme

Maurer, Christoph; Bueno Unzeta, Bruno |

Vortrag

Presentation

|

| 2016 |

BIPV Technologien und Anwendungen - eine Übersicht

Sprenger, Wendelin; Ferrara, Claudio |

Konferenzbeitrag

Conference Paper

|

| 2016 |

Review of standards for integrating BIPV-modules in building facade and roof

Rehde, Franziska; Szacsvay, Tamás; Peppas, Antonis; Frontini, Francesco; Marchi, Francesca; Hecker, Robert |

Bericht

Report

|

| 2015 |

Simple models for architecture with BIPVT or BIST

Maurer, Christoph; Sprenger, Wendelin; Lämmle, Manuel; Kuhn, Tilmann |

Konferenzbeitrag

Conference Paper

|