| Duration: | 05/2024 - 04/2027 |

| Contracting Authority/ Sponsor: |

Federal Ministry of Education and Research (BMBF) |

| Project Partners: |

|

| Project Focus: | |

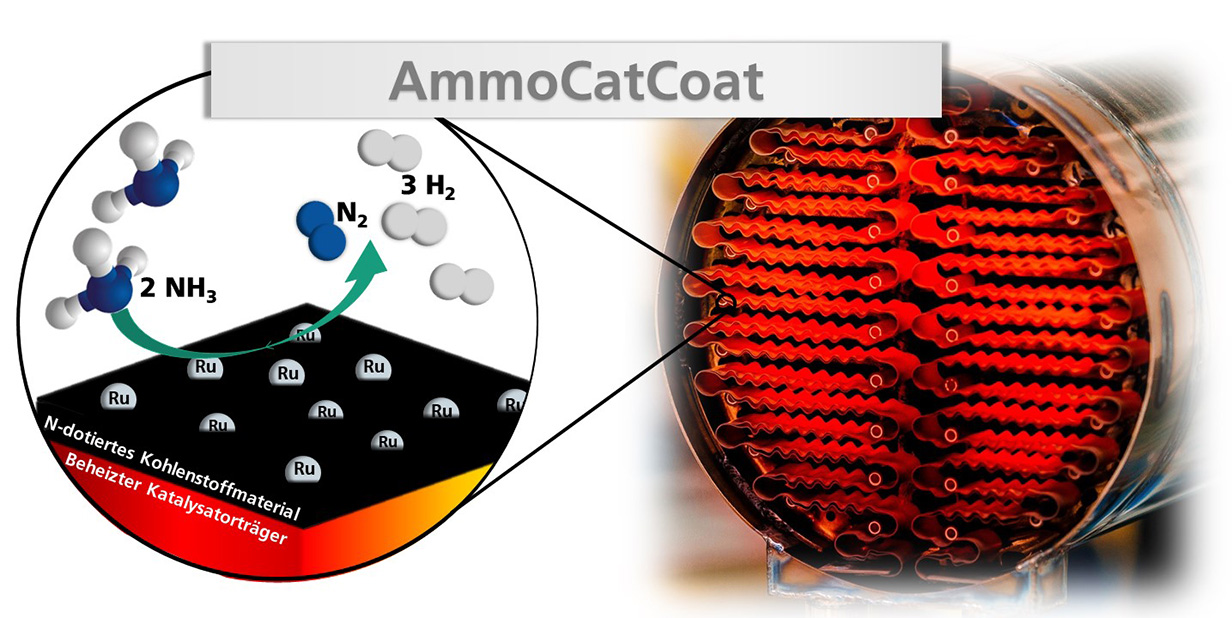

AmmoCatCoat – Ammonia reforming with electrically heated catalyst supports coated with biomass-based carbon materials

In the “AmmoCatCoat” research project, Fraunhofer ISE is working with partners from industry and research to investigate catalysts with novel biomass-based carbons as a ruthenium carrier material for more efficient, sustainable and cost-effective hydrogen production from ammonia. The activity of catalysts is evaluated particularly at low process temperatures. At the same time, the carbon materials are being adapted so that conventional coating methods can be used in order to be able to utilise electrically heatable catalyst carriers in the future.

Green hydrogen plays an outstanding role in the energy transition as an energy carrier. Hydrogen can be chemically stored in the form of ammonia for transportation. As a carbon-free energy carrier that can be easily liquefied, ammonia is an efficient and cost-effective transportation option, partly because the shipping and port infrastructure for transporting industrial quantities is already in place. Once it arrives at its destination, hydrogen can be released again in a process known as ammonia cracking, reforming or decomposition.

Fraunhofer ISE is leading the following work packages:

Synthesis of biomass-based carbon materials as a carrier material for ruthenium

To achieve particularly efficient reactions, biomass-based carbons are being investigated as carrier material for ruthenium. Natural polymers from plants, wood, algae, or waste products from agriculture or shellfish can be used as starting materials. The use of biomass reduces dependence on fossil raw material imports and enables the diversification of supply chains. Ensuring energy supply security would be strengthened, and using sustainable biomass can remove CO₂ from the Earth's atmosphere.

An important criterion for the materials is their resistance to the corrosive medium ammonia, even at high temperatures. At the same time, the carrier material must guide the reactants to the active ruthenium centers. Fraunhofer ISE optimizes these properties by varying parameters such as reaction time and temperature as well as the sequence of processes.

Catalyst production and investigations for ammonia cracking processes

The focus of this work package is on discussing a suitable method for metal deposition and the resulting, scalable catalyst synthesis recipe. The investigation of the influence of ruthenium on the stability of the carbon material is an important basis for subsequent activity measurements.

Coating methods with biomass-based carbon materials

Coating processes with ceramic washcoats containing precious metals are state of the art both for exhaust gas aftertreatment systems and for electrically heatable catalytic converters. The challenge in the “AmmoCatCoat” project is to coat the catalysts with carbon-based washcoats. Fraunhofer ISE is investigating the extent to which existing processing and coating methods can be adapted or whether completely new manufacturing methods are required in order to take account of the fundamentally different material properties of carbon compared to conventional coatings (e.g. risk of dust explosion).

The methods will then be demonstrated under real technical conditions on a pilot plant scale. Technical assessments for scaling up the production of the carbon materials, the coating processes and a process concept round off the project in preparation for industrial application.

The “AmmoCatCoat” project has a total volume of around EUR 2 million, is funded by the Federal Ministry of Education and Research (BMBF) as part of the Material Hub Initiative and the funding priority “Resource Sovereignty through Material Innovations Module 1 - Materials for Process Efficiency” and will run for three years. Funding reference: 03XP0613F