| Duration: | October 2012 - September 2016 |

| Contracting Authority/ Sponsors: | European Union |

| Project Partners: | Danish Technological Institute, Eidgenössische Material- und Prüfanstalt, Universität von Ljubljana, Asahi Glass Europe, MicroShade, EControl-Glas, Scandia Windows |

| Project Focus: |

WINSMART – Intelligent and Energy-Efficient Windows, Based on New Material Combinations

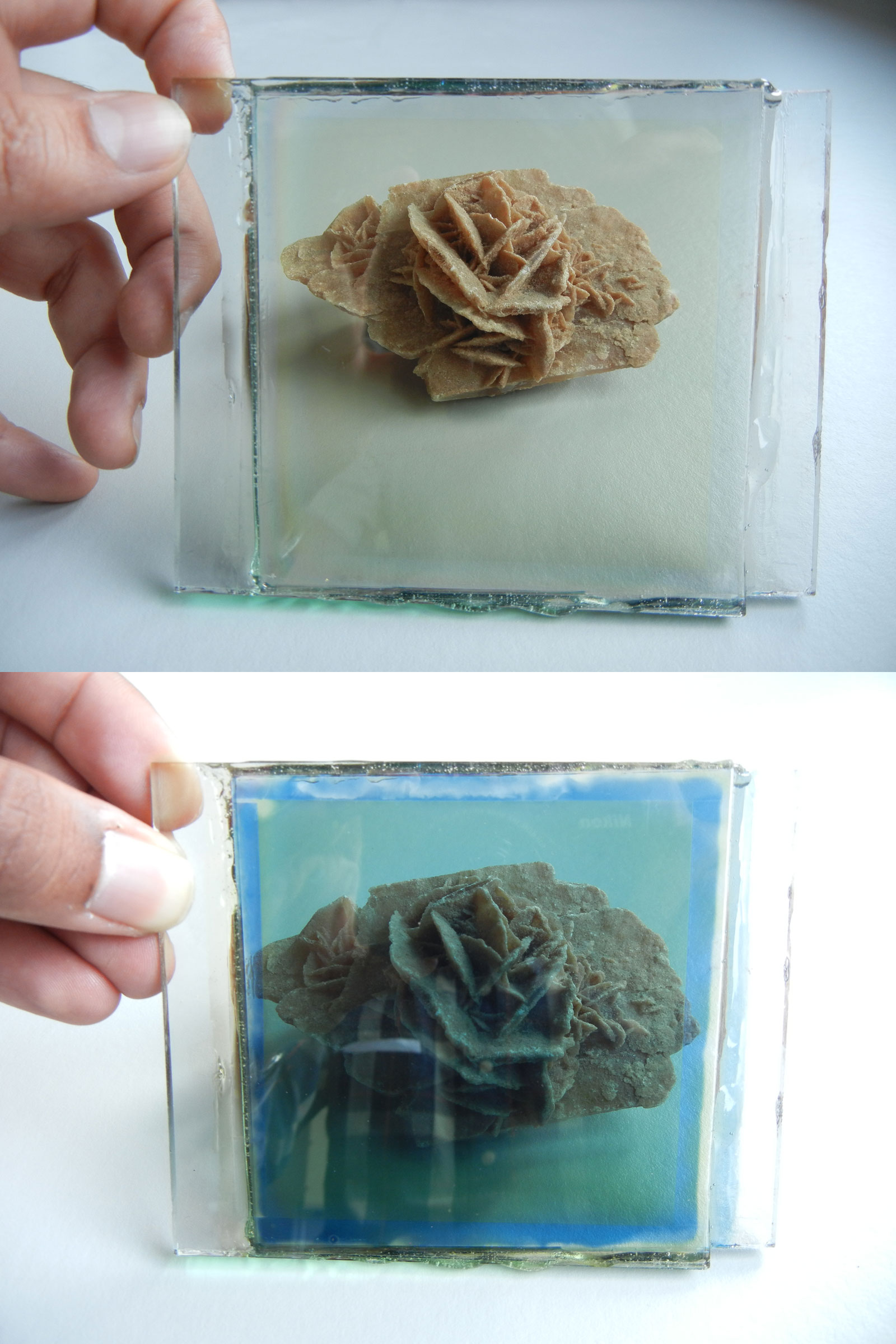

The EU-funded “Winsmart” project develops windows that improve the energy efficiency of buildings. Research focuses on the development of vacuum insulation glass (VIG). Here the gap between the two glass panes is evacuated, which can result in excellent thermal insulation also for very thin glazing. Another focus is the development of electrochromic and photochromic windows. Electrochromic windows can switch between transparent and dark by applying a voltage. One type of the electrochromic windows investigated here uses redox salts in electrolytes. Thus, it can achieve a strong contrast at high transmission in bleached state. The photochromic windows get dark when illuminated. They brighten again in the case of low light intensity.

Photochromic windows combine components from electrochromic windows and dye solar cells. The result is a porous electrochromic tungsten oxide layer on a porous titanium oxide layer, whose surface is covered with a dye. These layers are in connection with a redox electrolyte, which contains lithium iodide and lithium tri-iodide as redox salt. The dye is excited when illuminated. It emits electrons to the tungsten oxide via the titanium oxide, and colors it blue. At the same time, electrons are transferred from iodide to the dye and lithium ions enter the tungsten oxide layer. By connection to an approx. 1 nm thin catalyst layer, the system can be bleached again. Fraunhofer ISE already submitted a patent application for photochromic windows more than ten years ago. At that time, the layers were made in a chemical sol-gel process. Fraunhofer ISE has been able to manufacture these layers using sputtering in a PVD (physical vapor deposition) process common in window glass coating. One of the challenges was to achieve sufficient porosity that does not only allow fast diffusion of the ions in the layers, but also of the dye during dye adsorption. Another challenge was the optimum adjustment of the relevant layer properties, in particular, of the redox potential of tungsten oxide and of the loss currents, as well as of the surface condition of titanium oxide for efficient dye adsorption for layer thicknesses below 200 nm.