| Duration: | June 2015 - July 2015 |

| Contracting Authority/ Sponsors: | DLR |

| Project Partners: | National Renewable Energy Laboratory (NREL) |

| Project Focus: |

Very Low Angle Beam Spread in PMMA after up to 27 Years as Concentrator Lens in the Sun

Concentrator photovoltaics (CPV) follows an alternative approach to conventional flat modules. In the case of photovoltaic flat modules, large-area semiconductors collect the sunlight and convert it directly into electric energy. In contrast, concentrator photovoltaics uses very small solar cells and cover the large area with optics that focus the light. These large-area concentrator optics are mostly Fresnel lenses, often made of polymethyl methacrylate (PMMA). In photovoltaic power plants, these are subjected to weathering and intensive solar irradiation. We investigated material samples of lenses that were used up to 27 years in power plant operation at our measuring system for high-resolution analysis of very low angle beam spread (VLABS).

In lens-based CPV modules, the planar front side of the Fresnel lens is also the outer surface of the module. Many years of intensive solar irradiation in power plant operation and unprotected weathering stress the material of the Fresnel lenses. NREL intensively investigated PMMA lenses from different power plants after up to 27 years of operation. Fraunhofer ISE supported these investigations with measurements at our measuring system for high-resolution analysis of very low angle beam spread (VLABS).

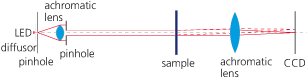

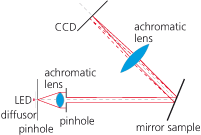

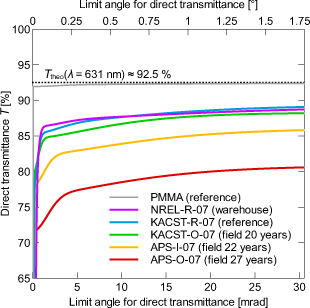

The lens structure on the backside was ground off from the PMMA lenses; however, the front side remained unchanged. This way, material samples planar on both sides were available. The VLABS measuring system was specially developed for the investigation of beam widening due to very low angle beam spreading during reflection on mirrors and transmission through lens material. For examples, scratches, material clouding, or dust on the surface increase this beam widening. They can significantly reduce the efficiency of a concentrator photovoltaic system. Fig. 1 and 2 show the schematic structure of the VLABS measuring system. Detailed knowledge of the CCD sensor enables the precise measurement of the angle distribution of monochromatic light with a resolution of 0.05 mrad (0.0029°) and the absolute measurement of the directed transmission with an accuracy of 0.5 %. As different wavelengths are available for the measurement, the spectral characteristics of very low angle beam spreading can also be investigated as needed. Fig. 3 shows the measuring results for material samples from concentrator lenses that were used up to 27 years in power plant operation as measurement example.

A new, planar PMMA panel demonstrates as reference sample that there can be very little light scattering in PMMA. However, the NREL-R-07 and KACST-R-07 samples that were not installed in the power plant already scatter the passing through light significantly more than the PMMA reference sample. It can also be seen that light scattering at the material used in power plants increases after approx. 20 years of operation. These angle-resolved distributions of very low angle beam spreading can for example be used in computer simulations to predict the influences on electrical yield of a CPV system. The type of materials or surface defects causing light scattering cannot be determined based on measurements alone. The measuring results of Fraunhofer ISE are thus interpreted in the overall concept as part of comprehensive lens material investigations at the NREL. We would like to thank David Miller from NREL for the provision of samples.