| Duration: | October 2015 - September 2019 |

| Contracting Authority/ Sponsors: | Federal Ministry for Economic Affairs and Energy (BMWi) / Projektträger Jülich (PTJ) |

| Project Partners: | MAHLE Behr GmbH & Co. KG; SPÖRL KG Präzisionsdrahtweberei; Institut für Mechanische Verfahrenstechnik (IMVT), Universität Stuttgart; Institut für Chemische Verfahrenstechnik (ICVT), Universität Stuttgart |

| Project Focus: |

Thermal Fabric (Thermogewebe)

Technological Design and Thermal Fluid Dynamic Characterization of Wire Fabric-Based Micro Heat Exchangers with High Performance Potential

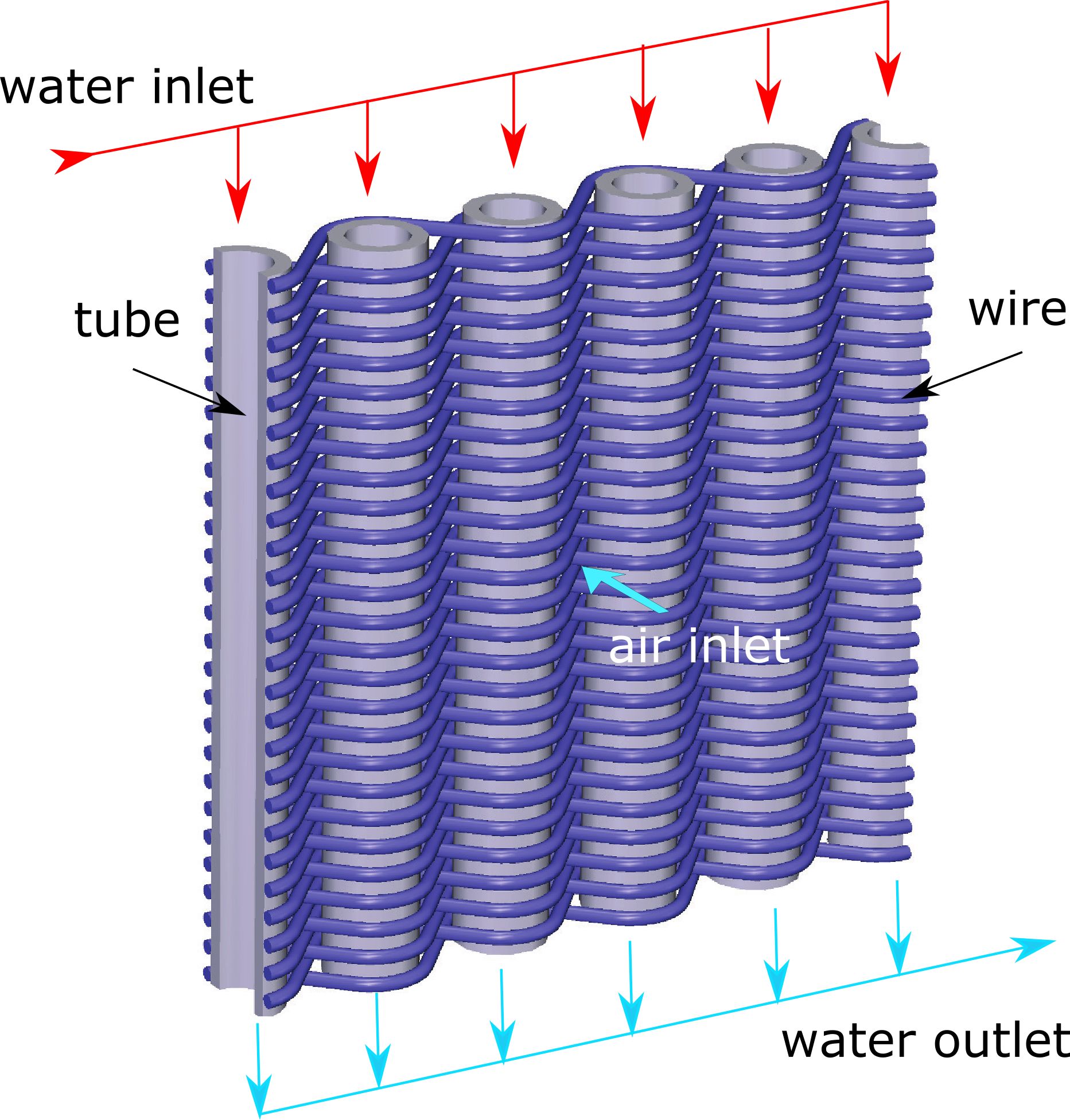

New heat exchanger designs based on micro tubes interwoven with metallic wires are being investigated within the joint project "Thermogewebe" (Thermal Fabric).

The objectives of the project are the experimental characterization and the theoretical description of the heat and mass transfer of wire meshes for the evaluation of their suitability for various thermal applications.

The aim of the project is the provision of manufacturing technologies for the production of fabric-based heat transfer structures with high power density. It will also be investigated to what extent such a heat exchanger structure can be used as a reactor or catalyst structure for chemical reactions.

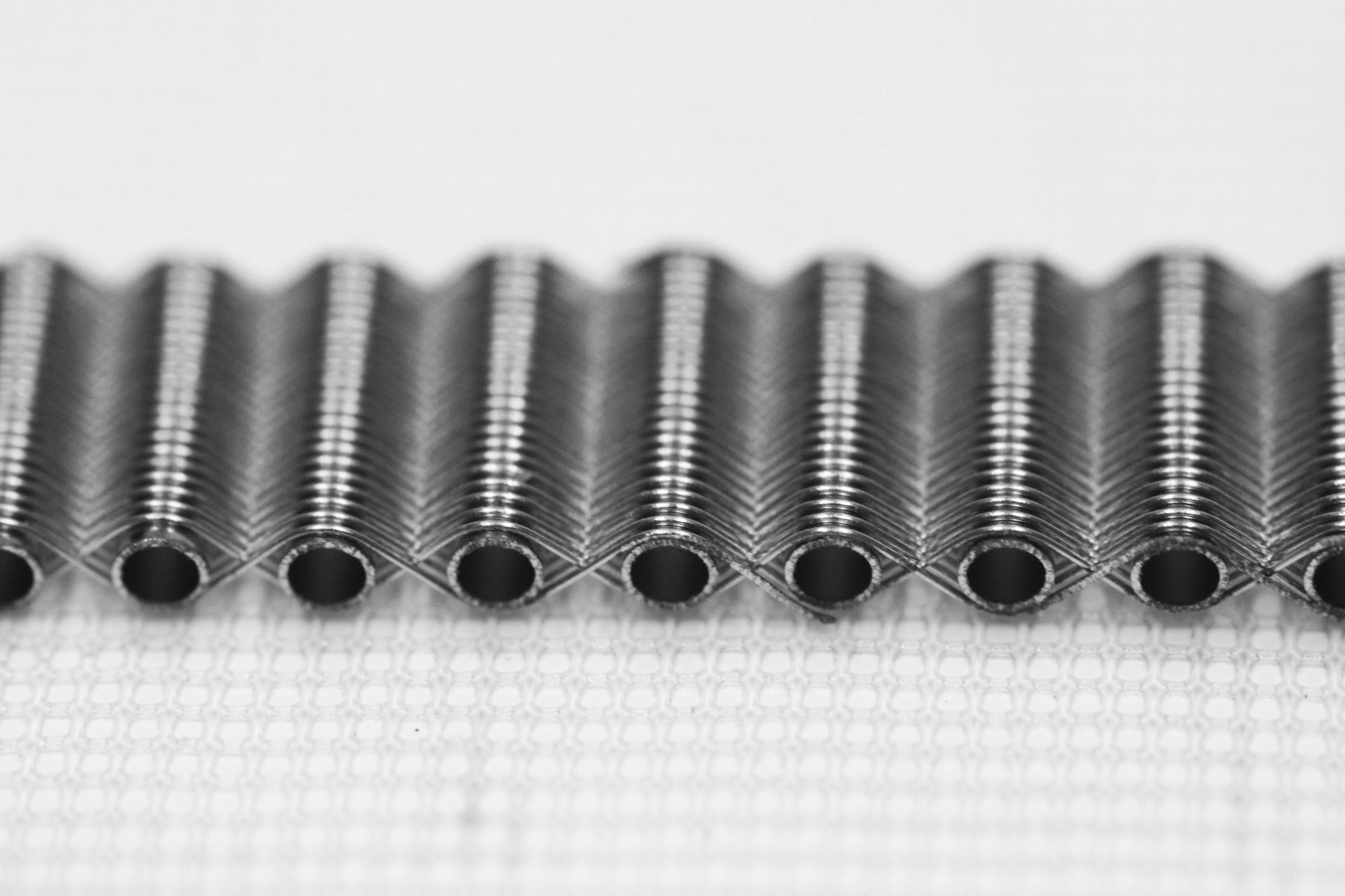

The core of the project is a manufacturing process developed by the company SPÖRL KG in which capillary tubes are woven into a metallic wire structure and firmly bonded with each other.The use of textile manufacturing processes for the manufacture of components for heat transfer allows new geometric design possibilities and the realization of special properties such as high heat transfer at the surface and homogeneous temperature distribution.

MAHLE GmbH further integrates the flow-through fabric elements into a heat exchanger and evaluates them together with the partners for various applications.

Fraunhofer ISE focuses on the measurement and evaluation of heat exchangers for use as air-to-water heat exchangers and as heat transfer structures in latent heat strorage storages. For this purpose, dimensioning and experimental characterization are carried out on the component level.

This is supported by the analysis of the transport mechanisms in terms of simulation-based identification of the heat and mass transfer as well as pressure loss characteristics of the structures and the experimental verification of the physical laws. The simulation-based work is carried out in close coordination with the University of Stuttgart and MAHLE GmbH.