| Duration: | 09/2018 - 08/2024 |

| Contracting Authority/ Sponsors: |

Federal Office for Agriculture and Food (BLE) as project sponsor for the Federal Ministry of Food and Agriculture (BMEL). |

| Project Partners: | Innotech Ingenieursgesellschaft mbH (Deutschland); Kenya Industrial Research and Development Institute (KIRDI, Kenia); Kenya Marine and Fisheries Research Institute (KMFRI, Kenia); Technical University of Mombasa (TUM, Kenia) |

| Project Focus: |

SolCoolDry – Solar Ice Production and Drying

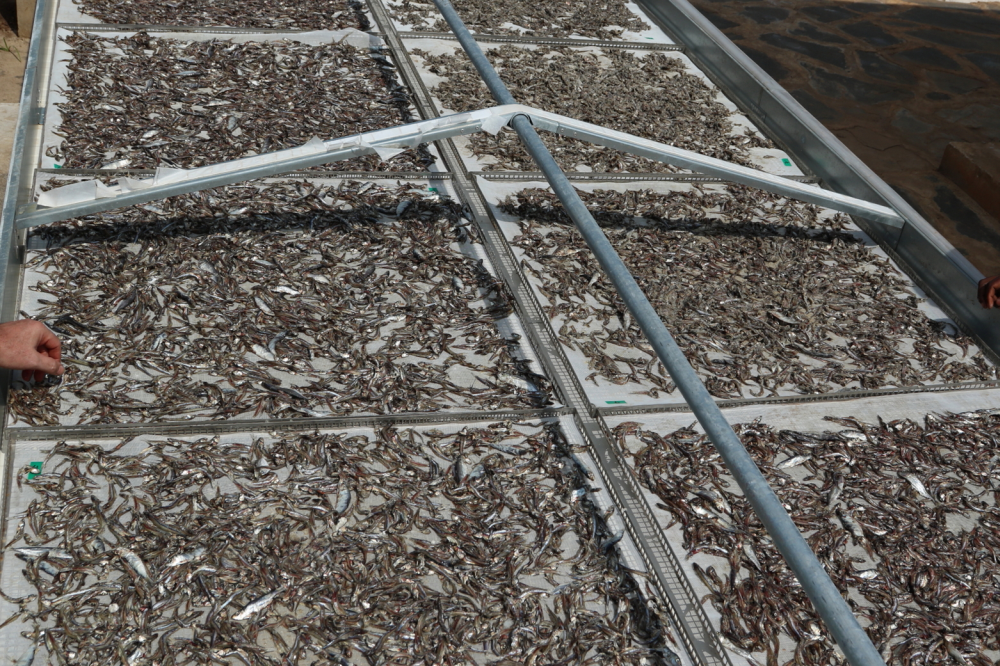

In Kenya's coastal regions, the lack of cold storage facilities and suitable technologies for preserving fresh produce leads to considerable losses. Both fishermen and farmers suffer from this situation and are forced to sell their produce fresh to traders as quickly as possible or at uneconomical prices. The warm weather in the region accelerates spoilage and leads to post-harvest losses, especially of fish. It is also difficult to dry fish during the rainy season and at night. Drying in the sun in open areas is prone to contamination and results in poor quality fish that cannot find access to quality markets.

In the project, two solar-powered systems for producing ice and drying fish were developed and set up with local partners. Photovoltaics and electrical storage technologies as well as solar thermal energy, heat pumps and thermal storage systems are used to generate and supply the required energy. The project is being implemented in close cooperation with the partners in Kenya in order to ensure sustainable operation of the systems beyond the project duration.

The "SolCoolDry" project aimed to support fishermen and farmers by developing and setting up a 100% solar-powered, off-grid system for drying and producing flake ice. Two systems were set up in the project. One of the systems uses solar thermal energy for heat generation, while the second system is equipped with a heat pump and an additional biomass boiler as backup. Both have two solar tunnel dryers, one with a heating system for optimized night-time operation and the other designed as a simple solar dryer.

The ice machines are supplied via PV; at the first site via inverters and battery storage to generate a so-called stand-alone grid and at the second site via DC direct coupling using a frequency converter.

While the ice is mainly used by fishermen and fishmongers for cooling during transportation between catch and sale, the dryers are used to produce storable products, mainly dried fish or other products with premium nutritional value, texture and taste. Users of the facilities are the local population as well as traders. Until now, fish has traditionally been dried at both sites largely on nets and tarpaulins spread out on the ground. This means that product quality is directly dependent on sunlight and the weather.

The use of monitoring systems makes it possible to keep an eye on and support operating behavior remotely. As a result, minor technical problems have so far been successfully resolved on site.

The SolCoolDry system in Mwazaro, on the south coast, has been operated by the local Beach Management Unit since August 2022. The ice machine is currently the only one in the wider area that still produces high-quality ice and also operates independently of recurring power outages.

The second system in Muhuru Bay on Lake Victoria was handed over to the Kenyan social enterprise WeTu for long-term use in August 2024. Due to the year-round fishing in the lake, there is a very high demand for ice here, which can only rarely be met even with the new system. 700 kg/d are sufficient for around 2100 kg of fish. The local cooperation with WeTu at this location provides water treatment, which is the basis for the production of clean ice.