| Duration: | January 2019 - December 2023 |

| Contracting Authority/ Sponsors: | European Union |

| Project Partners: | Fraunhofer ISE; CIEMAT (Spain); CNRS (France); ENEA (Italy); DLR (Germany); CEA (France); Universidade de Évora (Portugal); ETH Zurich (Switzerland); IMDEA Institutes (Spain); The Cyprus Institute (Cyprus); FRA (Germany); LNEG (Portugal); Middle East Technical University (Turkey); Universidad de Almería (Spain); EURONOVIA (France); ESTELA (Belgium) |

| Website: | https://sfera3.sollab.eu/ |

| Project Focus: |

SFERA-III – Solar Facilities for the European Research Area

The project intends to engage all major European advanced solar laboratories with relevant and recognized activities in the technology field of concentrated solar radiation and Concentrated Solar Power (CSP). It provides access to high-quality research infrastructures (RIs) and services to European and non-European researchers from academy and industry. They can conduct first-class experimental research focusing on CSP and CSP-related activities but also other high temperature and high flux applications for research and industry, free of charge. Through SFERA-III researchers can access the R&D infrastructures of the Fraunhofer ISE.

Within the framework of the SFERA-III project, Fraunhofer ISE also offers training for industry on various topics. In 2019, an industry training course on central receivers and heliostats took place. Furthermore, a summer academy for postdoctoral students was organized in September 2019, which will take place again in 2021. The same year, Fraunhofer ISE will offer a training course on industrial process heat and a workshop on the calibration of soiling measurement devices.

The fifth transnational access campain has been launched in december 2022.

In 2019 many successful visitor projects took place at Fraunhofer ISE and we are looking forward to the new applications for 2021. A particular success was the project "EISSC" with researchers from the Politecnico di Milano. An extract from the SFERA III-website:

"This project is a success story for fruitful cooperation between researchers from different institutions, combining their expertise. The ambition and skill of the visiting researchers from the Politecnico di Milano combined with the expertise and infrastructure variety of measurement devices at the Fraunhofer Institute for Solar Energy Systems made obtaining highly valuable results in a short period of time possible."

For concentrated solar thermal power, energy storage and water treatment technologies, we develop materials, components, systems and processes. In addition to its R&D, the institute offers testing and certification procedures. Furthermore, it features an excellent laboratory infrastructure. In the SFERA-III project, we offer access to the following installations:

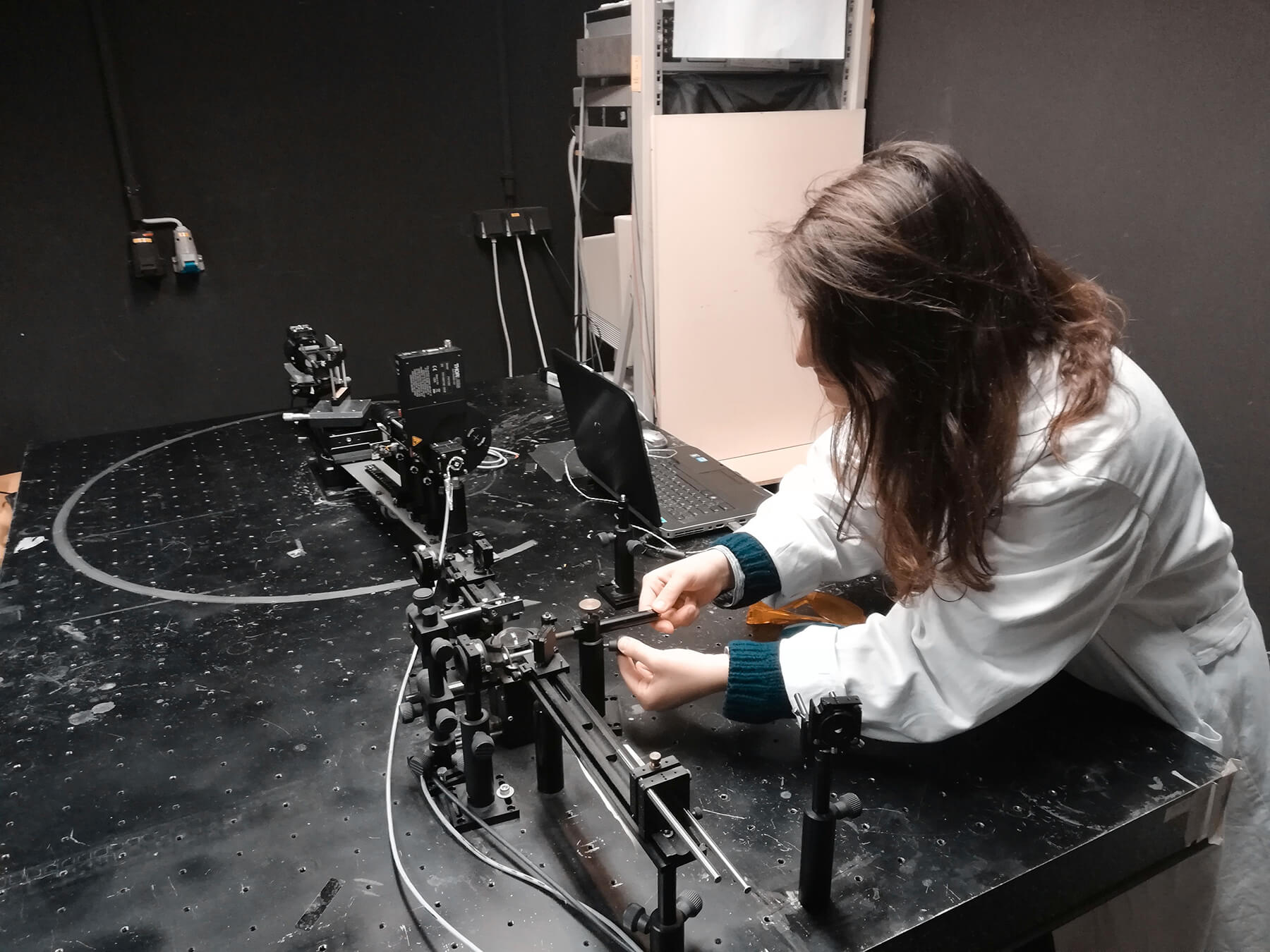

Concentrator Optics Laboratory – Optical testing and simulation of materials and components for concentrated solar thermal

The laboratory is equipped with instruments for characterization of solar reflectors (reflectance and scattering) and mirror facets (shape and slope). Specular reflectance can be measured for acceptance angles between 1mrad and 30mrad and incidence angles between 8° and 60° with the “VLABS” instrument. Shape and slope of mirrors are measured with deflectometry (with resolution from 1µm to 1cm, samples from 5cmx5cm to 6mx2m) or photogrammetry. For validation and impact assessment we offer support in optical simulations with ray-tracing (from components up to system simulations for Linear Fresnel (LFC), Parabolic Trough (PTC) and Tower systems).

Concentrator optics heliostat- and mirror test-field

The concentrator optics lab test field offers outdoor testing of heliostats, heliostat tracking, focal point tests, and outdoor exposure of solar mirrors and testing of soiling on curved and flat mirror facets. It is equipped with a heliostat, a flexible target for focal point analysis and exposure racks and parabolic trough mirror facets for soiling assessment.

Testing of materials and components for molten salt storage

The Lab for Thermal Energy Storage (TES-Lab) is equipped with laboratory set-ups for testing of molten salt materials, characterization of components for usage in molten salt environment (flow meters, valves, heating systems) and a single-tank molten salt facility. The storage vessel for testing of molten salt mixtures has a comprehensive temperature measurement system and wall heating measures to compensate heat losses and prevent salt mixing. We offer the evaluation of the salt stratification with special focus on the thickness of the thermocline zone of the storage tank during charging and discharging processes at various temperature differences (up to a maximum temperature of 550 °C) and various mass flow rates. Different salt mixtures and other fluids can be tested.

Further Information on High-Temperature Storage for Power Plants

Water treatment and desalination laboratory

The Water Treatment Lab is equipped with laboratory set-ups for testing of water quality, industrial anorganic waste water treatment and desalination. With a special focus on testing and application of membranes for the different technologies membrane destillation (MD), reverse osmosis (RO), electro dialysis (ED) and diffusion dialysis (DD) from lab-scale to industrial scale. We offer detailed simulation models of MD-membrane processes, dimensioning of advanced ED processes and flexible operation of RO-processes. Further we offer simulation of water treatment processes and water saving plans for CSP plants.

CSP Training course for industry at Odeillo, France – Central receivers: optics of heliostats fields

The course included theoretical and practical modules covering the following topics:

- Central receiver technologies and qualification: Typical thermodynamic processes for electricity and material production; storage technologies for solar tower; metrology of their power measurement; infrared receiver temperature measurement using UAV (drones).

- Heliostats fields design and operation: Heliostat field design optimization techniques and constraints such as latitude influence; raytracing software and design tools for heliostats fields; training with the free Solstice raytracing software; practical test case: visit of the wireless field of the solar tower Thémis at Targassonne; practical test case: visit of the wired field of the Solar Furnace at Odeillo.

- Characterisation of heliostats fields: Optical quality determination techniques (photogrammetry, deflectometry); demonstration of the optical calibration of solar tower heliostats; power distribution and aiming characterisation techniques.

Please visit the SFERA-III website (https://sfera3.sollab.eu/) to find all the basic information, like the access conditions, and the description of the Research Infrastructures, further information on the technologies, as well as services available, and the overall list of installations offered for access by each Research Infrastructure. The Application Form (SAF) and the ‘SFERA-III USER Proposal template’ can be downloaded from the website as well.