| Laufzeit: | 10/2016 - 11/2019 |

| Auftraggeber / Zuwendungsgeber: |

EU H2020 SPIRE (Grant no. 723729) |

| Kooperationspartner: | Arbeitsgemeinschaft – Erneuerbare Energie - Institut für Nachhaltige Technologien AEE INTEC Austria; VDEH-BETRIEBSFORSCHUNGSINSTITUT GMBH ; UNIVERSITA DEGLI STUDI DI PALERMO UNIPA Italy; CENTRO DE INVESTIGACIONES ENERGETICAS, MEDIOAMBIENTALES Y TECNOLOGICAS-CIEMAT CIEMAT Spain; DEUTSCHE EDELSTAHLWERKE SPECIALTY STEEL GmbH & Co. KG DEW Germany; SOLARSPRING GMBH SolarSpring Germany; AT & S AUSTRIA TECHNOLOGIE & SYSTEMTECHNIK AKTIENGESELLSCHAFT AT&S Austria; Electroniquel, SA ELECTRONIQUEL Spain, DEUKUM GMBH Germany, Associazione Italiana Zincatura AIZ Italy; UNIVERSITAET STUTTGART Germany, Tecnozinco S.r.l. Tecnozinco Italy; PSE Conferences & Consulting GmbH PSE-co Germany |

| Webseite: | rewacem |

| Projektfokus: |

ReWaCEM

Resource Recovery from Industrial Waste Water by Cutting Edge Membrane Technologies

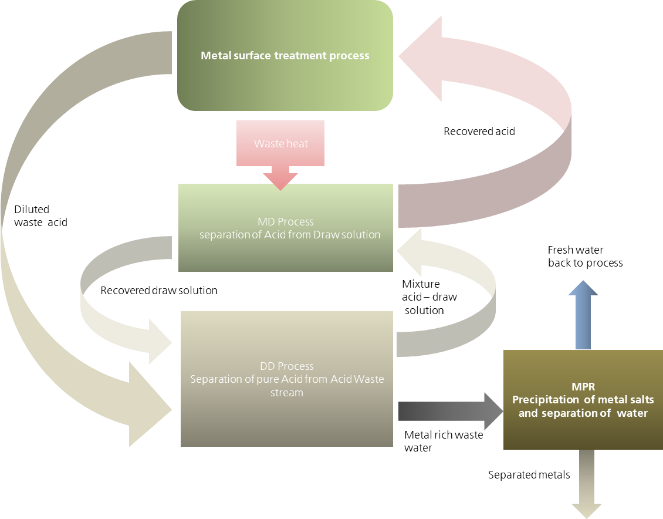

The steel processing industry uses very large quantities of various acidic process fluids, of which water - residual acid - metal salt mixtures must be disposed frequently in order to maintain the bath quality. In the EU project "ReWaCEM” coordinated by Fraunhofer ISE, treatment plants based on Diffusion Dialysis (DD) and Membrane Distillation (MD) have been developed, built and tested. Very high acid recovery ratios (>90%) were achieved. The acids recovered by DD are concentrated by MD and returned to the pickling baths. The metal salts remaining in the residual flow are precipitated and recycled. At Fraunhofer ISE, we built three plants for the recovery of sulfuric acid from electroplating, hydrochloric acid from hot-dip galvanizing and HF-HNO3 mixed acids from stainless steel pickling.

The ReWaCEM project aims at reducing water use, wastewater production, energy use, valuable metal resource recovery and minimization of water footprint by between 30-90% in the metal plating, galvanizing and printed circuit board industry. In order to achieve these goals, ReWaCEM adopts two cutting-edge membrane technologies suitable for the requirements of closed material cycles approaches and recovery concepts in metal processing industry namely: Diffusion Dialysis (DD) and Membrane Distillation (MD) as an integrated hybrid process. Four demonstration systems were developed, constructed and operated.

DEMO A: Hot-Dip Galvanizing TECNOZINCO – Carini, Italy, Recovery of HCl and Iron from hot dip galvanizing pickling solutions by using Diffusion Dialysis and Membrane Distillation coupled with a reactive precipitation unit. The recovery of acid, zinc and iron enables a closed loop operation. The pickling process can be operated more efficient constantly at higher acid contents since more than 85% of the acid from the blow down can be recovered and acid losses can be minimized.

DEMO B: Metal Plating ELECTRONIQUEL – Gijón, Spain, Recovery of Sulfuric Acid (H2SO4) and Copper from electroplating solutions with DD and MD. The main problems for ELECTRONIQUEL are associated with the variation in bath concentrations during operation, high loss of precious metals like copper and about 50 tons/year of waste to be disposed. Circular economy approaches with DD, MD and chemical precipitation will lead to significant waste reduction, recovery of valuable materials, reduction of operating costs, reduction of environmental pollution and an increase of plant productivity.

DEMO C: Steel Pickling DEUTSCHE EDELSTAHL-WERKE – Hagen, Germany, demonstration plant for mixed acid recovery. The waste acid from the stainless steel pickling process contains free hydrofluoric and nitric acid (HF, HNO3) which is recovered by DD and MD system. A comprehensive pre filtration unit was installed and tested in order to protect the DD modules.

DEMO D: Printed Circuit Board AT&S – Fehring, Austria, Recovery of fresh water, gold and palladium from the PCB production by applying MD. Precious metals like gold and palladium were lost with the rinsing water in the rinsing sink in the past. In the new concept rinsing takes place on top of the plating bath and rinsing water is continuously removed by MD at the same time to maintain the bath concentration and to recover the water in a closed loop.