| Duration: | 01/2018 - 5/2021 |

| Contracting Authority/ Sponsors: | European Union |

| Project Partners: | AZUR SPACE Solar Power GmbH, Heilbronn (Germany); Fraunhofer Institute for Solar Energy Systems ISE, Freiburg (Germany); Umicore, Brussels (Belgium); EV Group E. Thallner GmbH, St. Florian am Inn (Austria); III/V - Reclaim Schwar Jörg, Pleiskirchen (Germany); Commissariat à l'énergie atomique et aux énergies alternatives (CEA), Paris (France); Thales Alenia Space (TAS-F), Toulouse (France); Thales Alenia Space S.A. (TAS-B), Mont sur Marchienne, (Belgium); AIRBUS Defense and Space GmbH, Ottobrunn (Germany) |

| Website: | RadHard |

| Project Focus: |

RadHard

Ultra High Efficiency Radiation Hard Space Solar Cells on Large Area Substrates

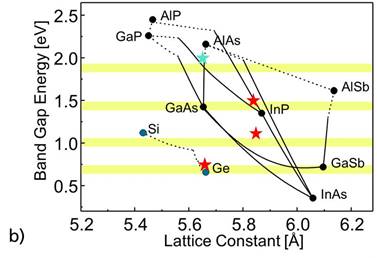

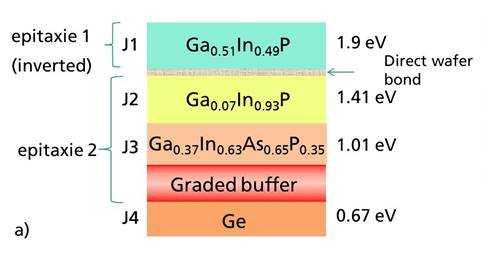

In RadHard we develop multi-junction solar cells for satellites with significantly improved radiation hardness and conversion efficiency. For this we develop novel semiconductor structures by a combination of metal-organic-vapor-phase-epitaxy and wafer bonding. Such solar cells will be superior for all missions with high electron and proton irradiation.

Electric orbit raising increases the radiation dose for space solar arrays significantly. This leads to the need for a more radiation resistant, highly efficient space solar cell. In the EU project RadHard, we propose a new wafer-bonded 4-junction structure which allows reaching begin-of-life efficiencies up to 34.7% (AM0) and efficiencies up to 30.8% (AM0) after 1*1015 cm-2 1-MeV electron irradiation. The high radiation hardness is a result of specific material properties of InP-rich compounds which benefit from significant defect annealing under typical operating conditions in space. Also the Ge bottom cell is known for its low degradation. First devices have been already demonstrated this year. In order to achieve ideal bandgaps and the desired radiation hard materials a combination of metamorphic growth and direct wafer bonding is employed for this device.

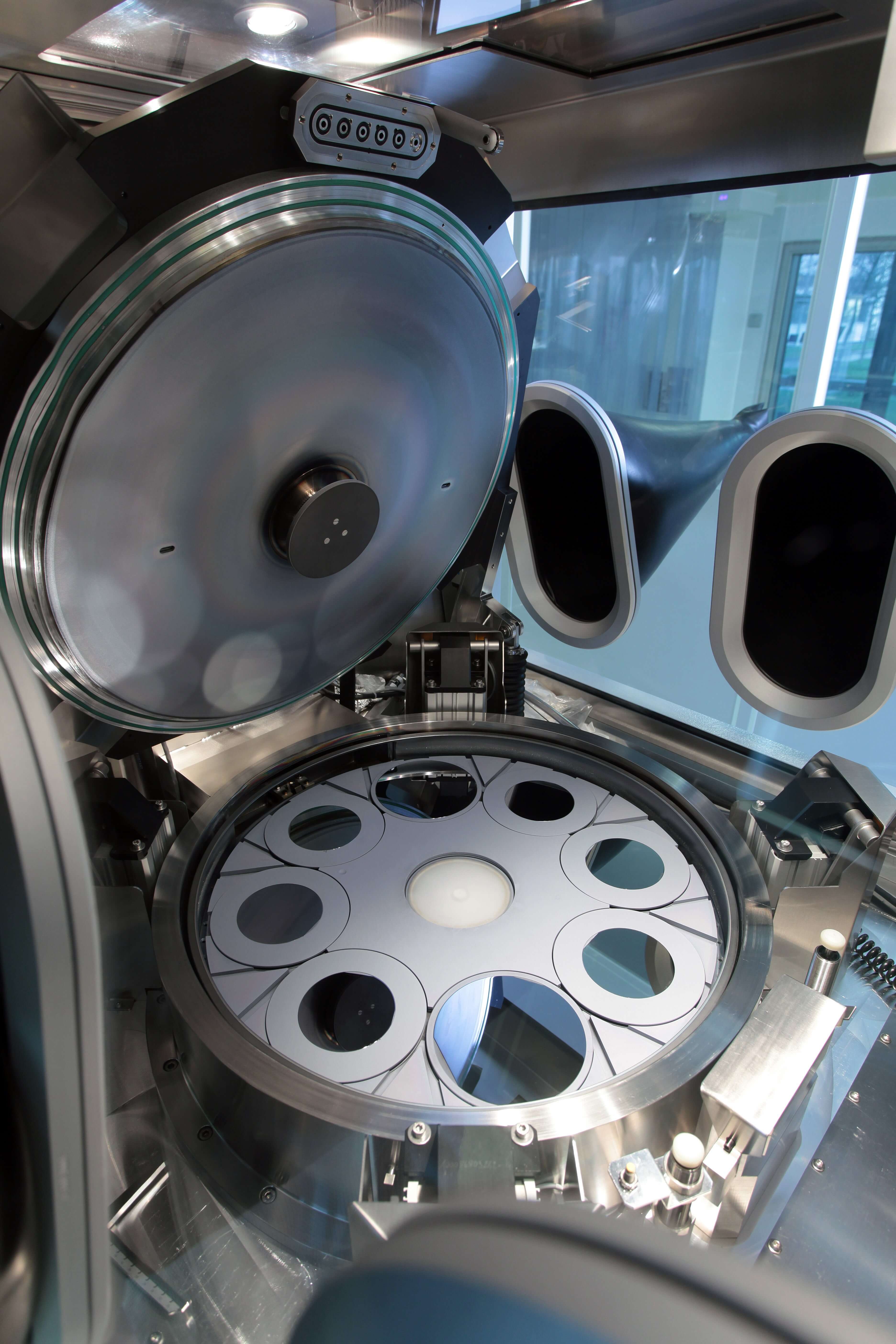

Fraunhofer ISE focuses on the epitaxy process development of the device structure on 100 mm GaAs and Ge wafers, the “end of life design” of each subcell by a full electro-optical modeling, the back end of line processing and electro-optical characterization of the four junction device under AM0 spectral conditions.

The work plan of RadHard is based on a parallel development of the new solar cell by semiconductor bonding and establishing existing solar cell manufacturing processes on 200 mm Ge wafers. At the end of the project, these development lines will be merged to demonstrate the commercial viability of the selected approach. Finally an industrialization plan for the new 4-junction semiconductor bonded solar cell will be elaborated. The project team is led by AZUR SPACE and covers all R&D aspects, from basic research on advanced materials at academic partners to device manufacturing in industrial environment and testing on higher integration level.