| Duration: | May 2015 - October 2018 |

| Contracting Authority/ Sponsors: | EU (H2020-GV-2014) |

| Project Partners: | Aimplas - Asociacion de Investigacion de Materiales Plasticos y Conexas; Dok-Ing Drustvo s Ogranicenom Odgovornoscu za Inzenjering i Unutarnjui Vanescu; AMV Design SRL; Durplastics SA; Cidete Ingenieros SL; European Thermodynamics Limited; Cleancarb SARL; Arkema France SA; Simoldes Plasticos SA; Atos Spain SA; Insero E-Mobility AS; ALKE SRL; Fundacion Para la Promocion de la Innovacion, Investigacion y Desarollo Tecnologico en la Industria de Automocion de Galicia |

| Website: | http://jospel-project.eu/ |

| Project Focus: |

JOSPEL – Efficient Passenger Comfort System Based on the Joule and Peltier Effect

The aim of the project „JOSPEL“ is to increase the efficiency, and thus the driving range, of electric vehicles. The focus of this project is the conditioning and the intelligent controlling of the energy flows. The Battery Technology Group at Fraunhofer ISE has the task of developing a battery system with an advantageous thermal management. The target is to decrease the amount of energy used for conditioning the battery cells, yet at the same time to increase the cells’ lifetime and ultimately that of the electric vehicle.

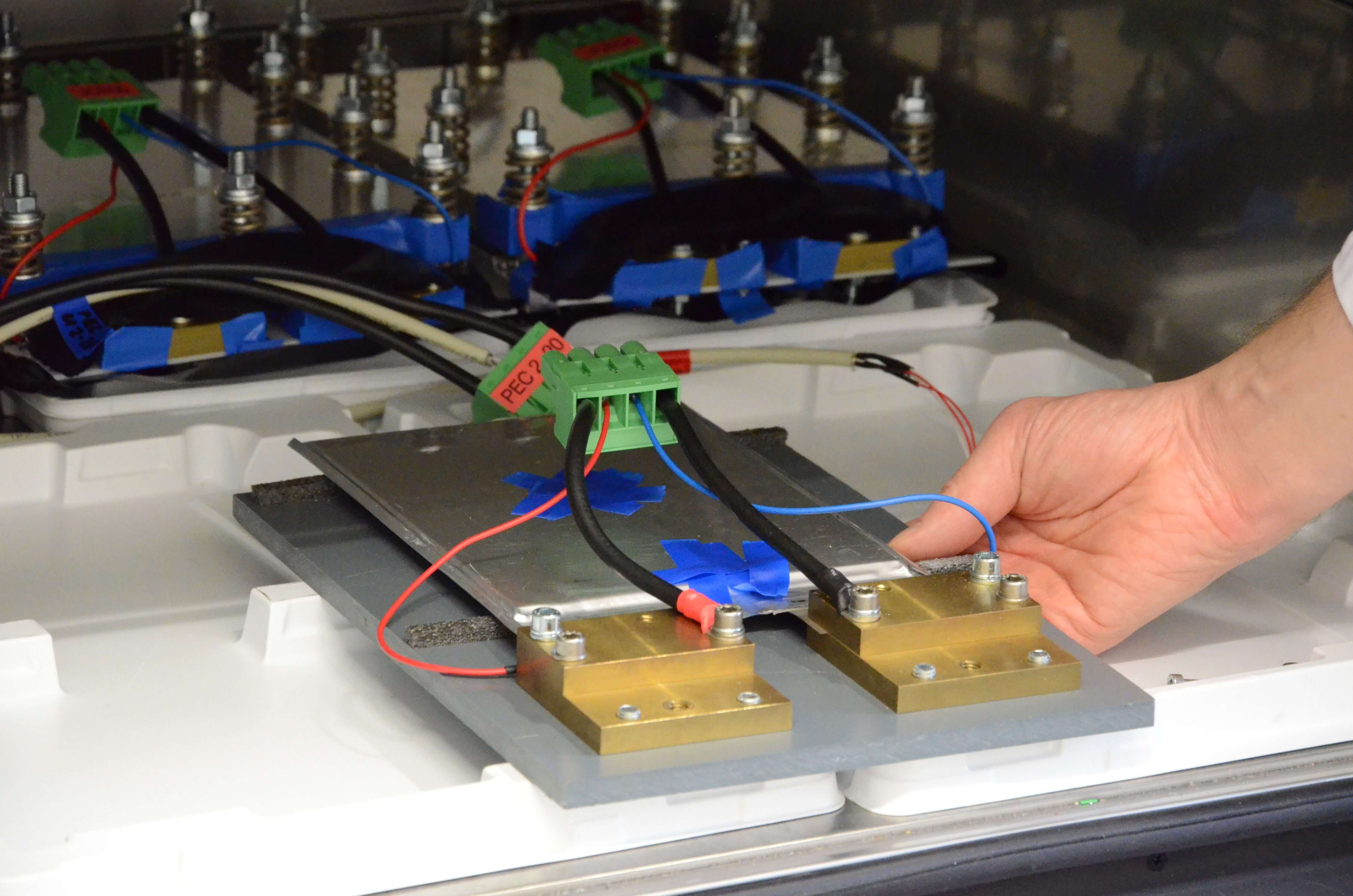

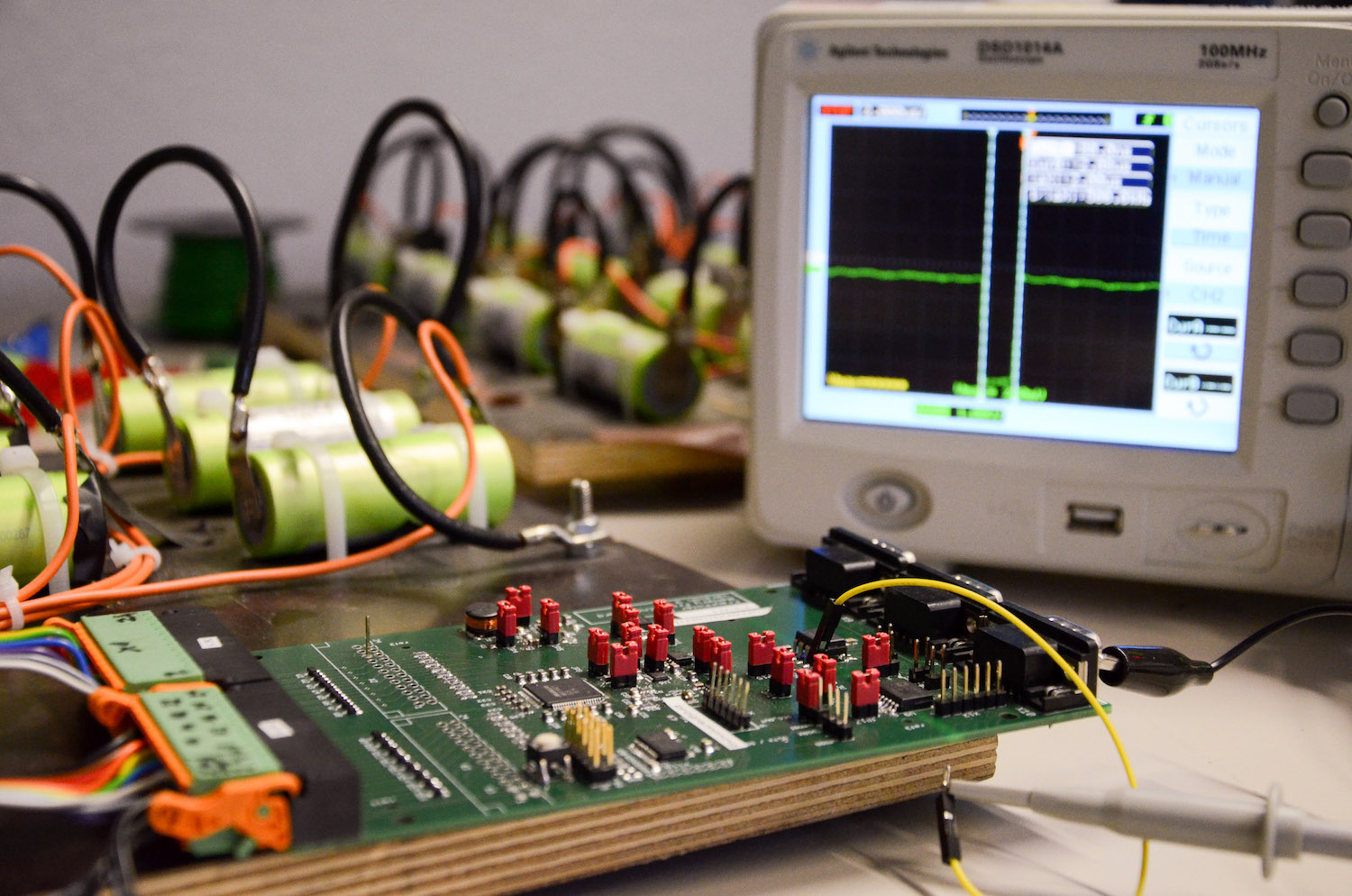

In the European research project JOSPEL, Fraunhofer ISE, together with its partners from industry, is commissioned to develop and build a battery system that ensures a higher efficiency as well as a longer lifetime. Since the two criteria are opposing at times, a simulation model was developed to calculate the effect of the thermal management on the cell aging. In the models, different operating strategies could be evaluated: thermal pre-conditioning of the cells prior to driving, various solutions for passively and actively cooling the battery system, etc. Thus, the ideal operating parameters for a long lifetime and an optimized system layout could be determined. In order to correctly simulate the battery cell behavior in the developed model, numerous tests were carried out first. Battery cells were measured in the laboratory under different environmental conditions (e.g. temperature, pressure, level of current, depth of discharge, etc.) and tested over many years.

In the last phase of the project, the battery system developed is going to be built and measured in operation. Thus, the real effect of the system and operational management optimizations will be proven.

On this topic from our research blog »Innovation4E«

Die »Thermal Comfort for Electric Vehicles – Longer driving range for electric vehicles through optimized battery managementBlog post by Maximilian Bruch

|

What is the ideal operating temperature for electric cars? At what temperature do they perform best? The participants of the European research project JOSPEL are addressing just these questions by assessing the optimization potential of electric vehicles. The project aim is to increase the energy efficiency and range of electric vehicles by applying efficient and cost-effective climate control solutions especially developed for battery electric vehicles. Experts at Fraunhofer ISE are working with industry partners on optimizing battery operation, with the goal of increasing battery lifetime through improved thermal management.

What is the ideal operating temperature for electric cars? At what temperature do they perform best? The participants of the European research project JOSPEL are addressing just these questions by assessing the optimization potential of electric vehicles. The project aim is to increase the energy efficiency and range of electric vehicles by applying efficient and cost-effective climate control solutions especially developed for battery electric vehicles. Experts at Fraunhofer ISE are working with industry partners on optimizing battery operation, with the goal of increasing battery lifetime through improved thermal management.