| Duration: | December 2011 - November 2014 |

| Contracting Authority / Sponsors: | German Federal Ministry of Economic Affairs and Energy (BMWi) |

| Project Partners: | Steca GmbH |

INET-PV – Multi-Functional Inverter for Grid and Stand-alone Service used for the Implementation of AC and DC Sources: Innovative Topologies of Grid Inverters for Small Grid-Connected Solar Power Systems

Multi-functional Inverter to Optimize On-Site Consumption

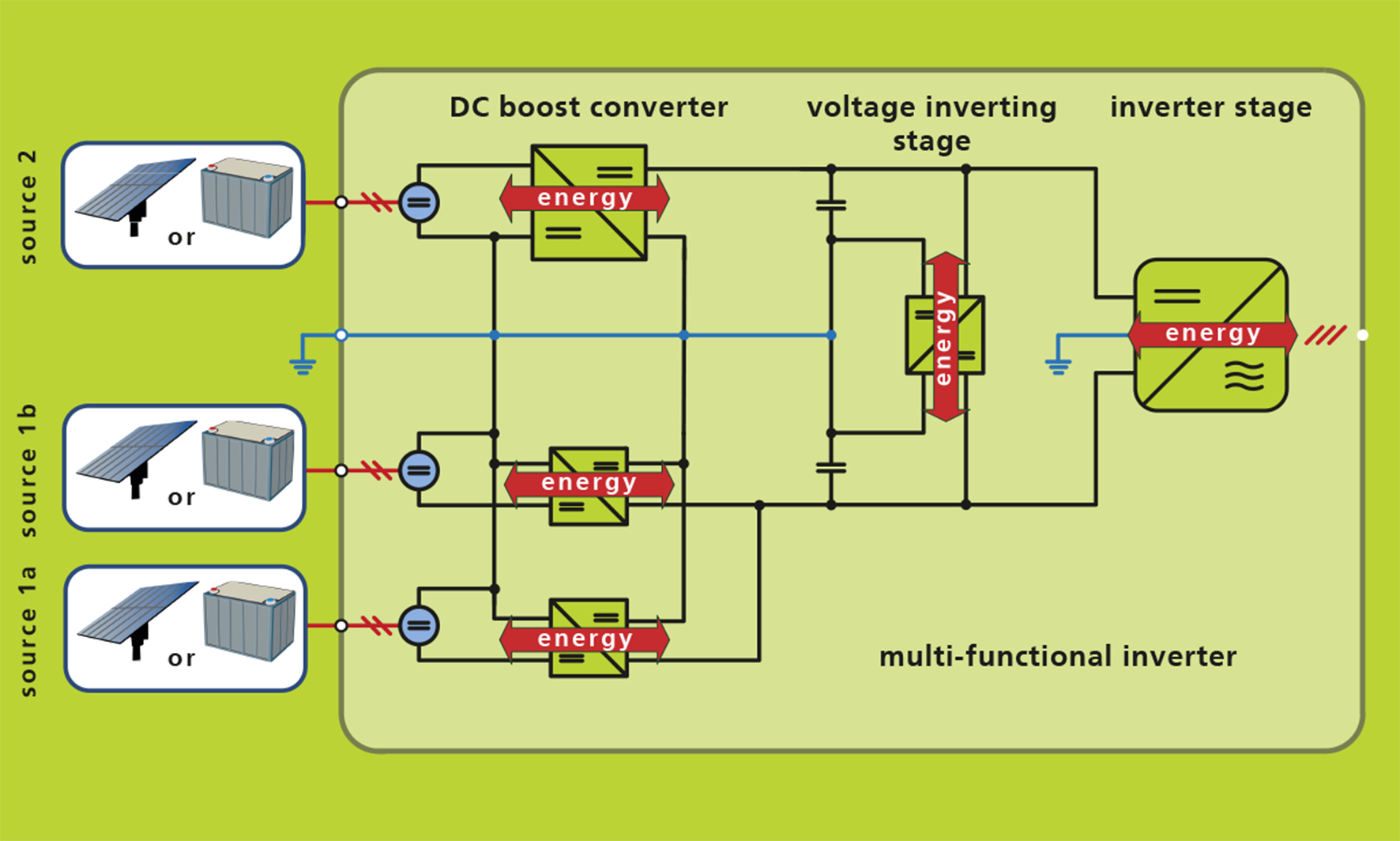

Rising electricity tariffs and significantly reduced feed-in tariffs according to the amended German Renewable Energy Act (EEG) are motivating increasing numbers of electricity consumers to consume their PV generated electricity on site. To make implementation technically simpler, we at Fraunhofer ISE have developed a very efficient three-phase inverter with innovative topology and three multi-functional inputs. The inputs can be connected as required to solar generators and / or batteries, so that all commonly available module and battery types (for voltages > 100 V) can be used. In this way, the user is able to choose the DC source flexibly, without needing complicated configuration of the inverter. Optimized on-site consumption is thus guaranteed.

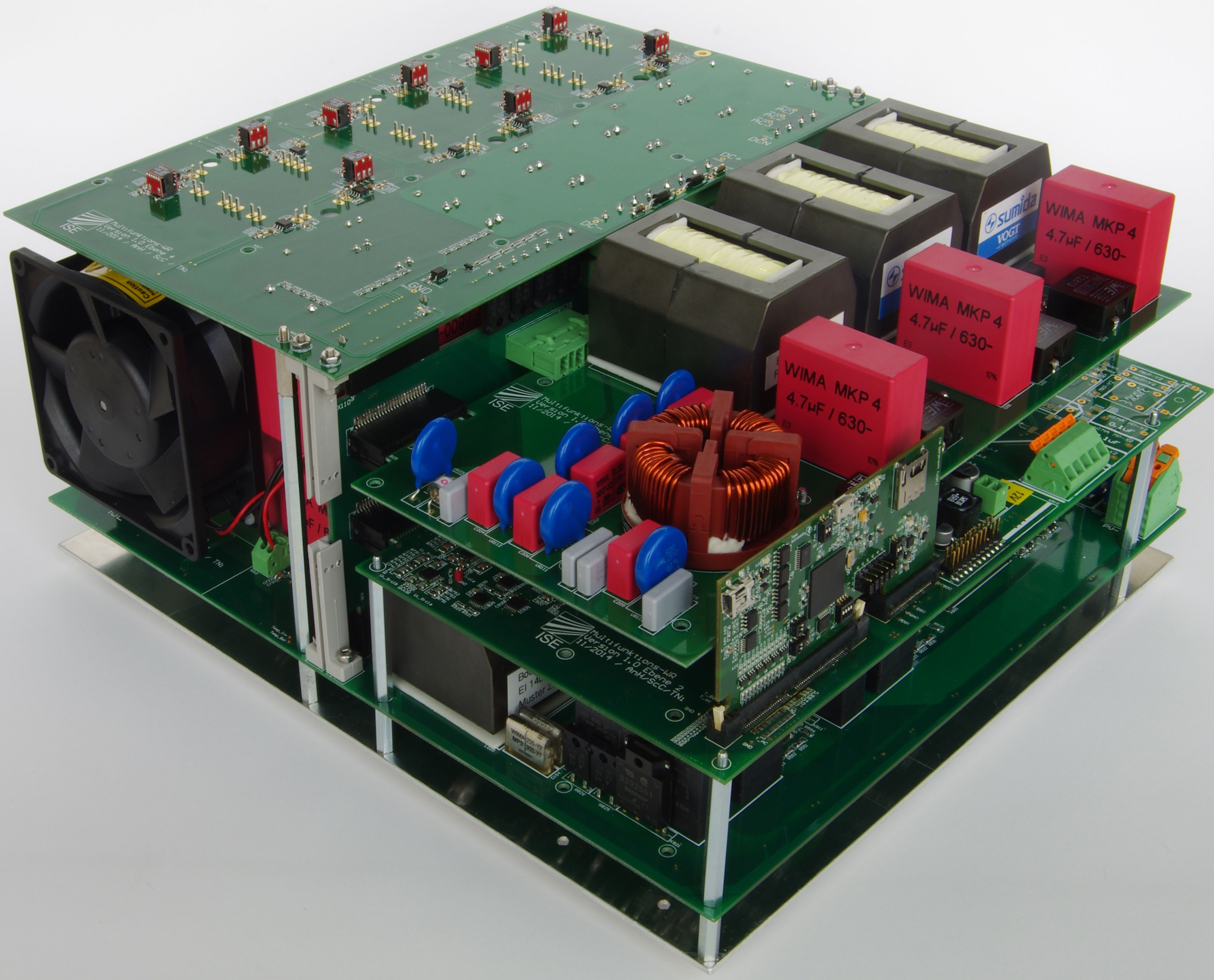

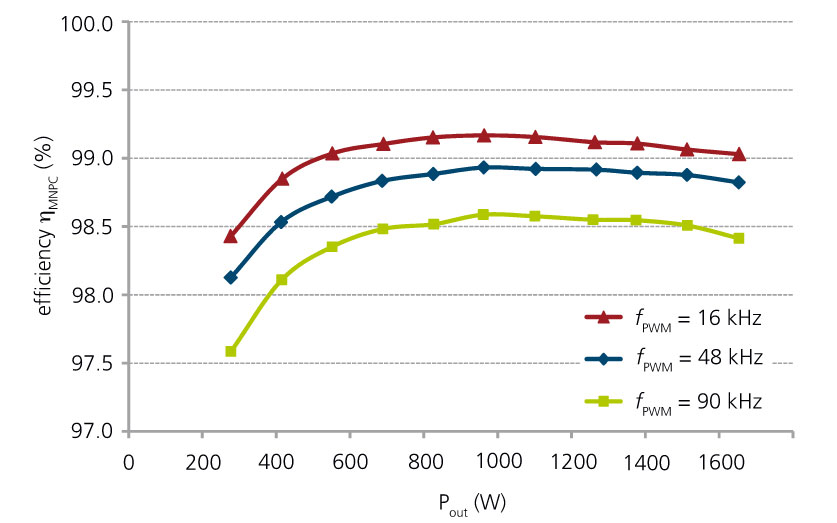

In order to integrate different DC sources into the system and implement all necessary energy flow paths, an innovative topology was chosen (Fig. 2). Due to its robustness against overloading, the system can also be used for stand-alone operation. In addition, we have developed controls with automatic source detection for all operating modes. The very compact demonstrator, with dimensions of 18.2 x 32 x 14.2 cm³, contains all necessary components and converter stages. It was designed with minimal empty spaces and gaps between the components. The converter stages were implemented with power modules of silicon carbide transistors. The resulting switching frequency of 48 kHz, which was achieved in all conversion stages, meant that small board-mounted inductive components could be used, which leads to considerable cost benefits in production. In addition, the smaller dimensions of the passive components reduce the material demand and thus also the system costs. In order to save weight, an active cooling aggregate was used which can provide cooling on both sides for the AC and the DC power modules, making it efficient with respect to costs, energy and occupied space. The complete system weighs less than 10 kg. It consists of a four-part DC stage with three input boosters and a quasi-resonant inverting stage, the DC link and a three-phase inverter stage with 3-level topology. The individual efficiency values of the stages are each about 98.2 %, despite the high switching frequency of 48 kHz (Fig. 3).