| Duration: | 12/2022 - 11/2025 |

| Contracting Authority/Sponsors: |

Federal Ministry of Economic Affairs and Climate Action (BMWK) |

| Project Partners: | Frenell GmbH, John Cockerill UVK GmbH, BASF New Business GmbH (associated) |

| Project Focus: |

HybridKraft – New Technologies for Integrated CSP/PV Hybrid Power Plants (ICPH)

Concentrating Solar thermal Power (CSP) plants can provide dispatchable renewable energy throughout the day but also during the night. Especially the ability of generating cost-competitive electricity for up to 15 hours after the sunset makes this technology very attractive and valuable. The thermal storage of the CSP plants, used primarily for nighttime production, can be one of the key factors in the establishment of a renewable-driven power network. Besides, in recent years, the cost of electricity generation through Photovoltaic (PV) plants, has decreased significantly. Therefore, combining these two power plant technologies can, on one side, decrease the production cost of CSP technology, on the other side increase the capacity factor (equivalent full time production time to maximum possible production) of PV plants.

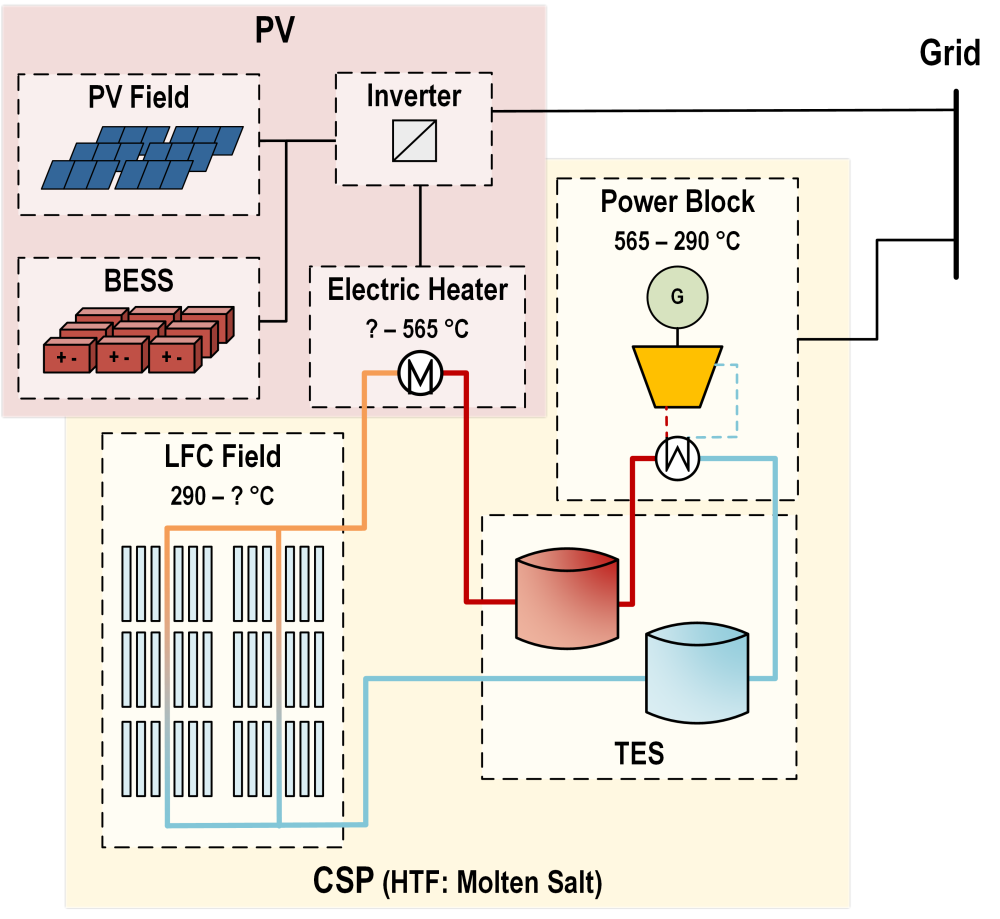

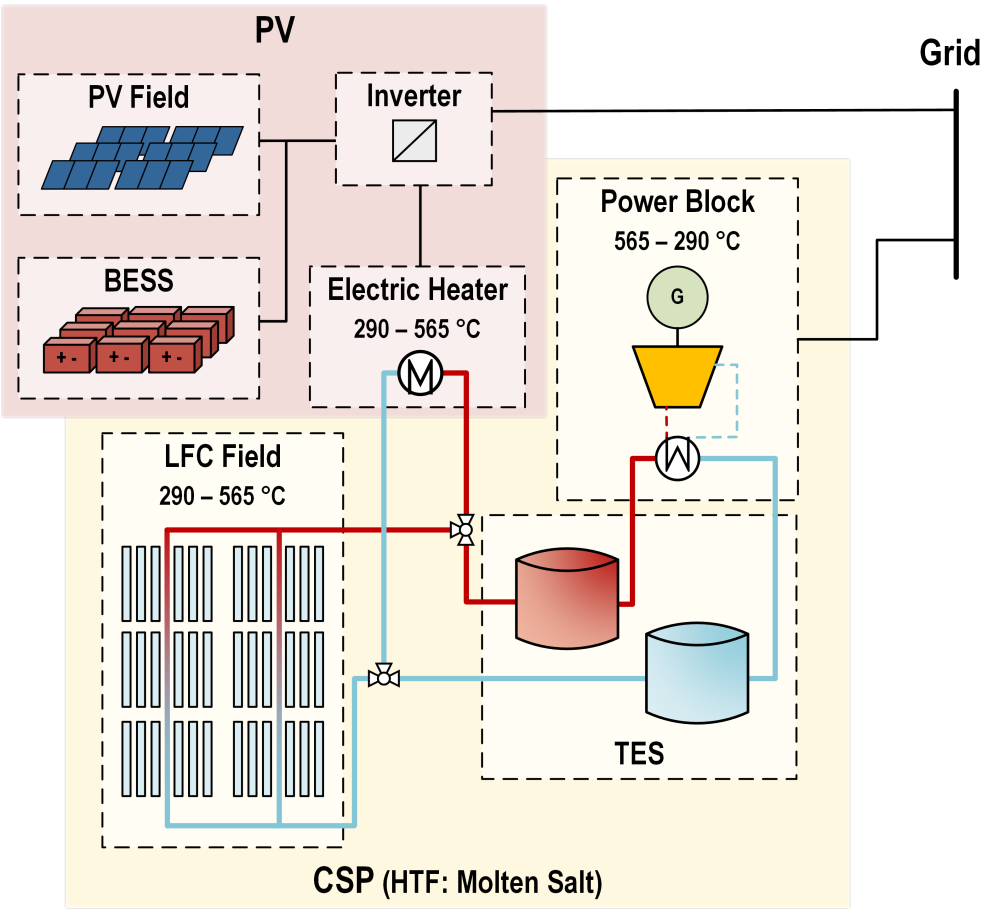

Fraunhofer ISE, together with three industrial partners namely John Cockerill UVK GmbH, Frenell GmbH, and BASF New Business GmbH as associated partner have set the goal to improve the design and performance of Integrated CSP and PV Hybrid Plant (ICHP) technology both on component and system integration levels. One efficient way to combine CSP and PV is to use an electric heater which uses excess electricity to heat up molten salt of the thermal storage. While smaller electric heaters are already used in other industrial processes, a low-cost, high-performance electric heater needed for ICPH power plants of 50 MWel and above has not been fully investigated. The main goal of HybridKraft is to develop such an electric heater for molten salt that suits the application in large scale power plants.

An innovative electric heater suitable for a thermal power of 50 to 100 MWth will be designed in this project. To this purpose a prototype with a relevant reduced size of 1 MWth will be designed and manufactured by John Cockerill with support from Fraunhofer ISE. The prototype will then be tested in a new molten salt test facility of Fraunhofer ISE in Freiburg. Based on the prototype design, test results and simulation studies, a design for a large capacity electric heater is developed.

Furthermore, Fraunhofer ISE will investigate the expected increase in system efficiency and flexibility of an ICPH plant by use of the developed electric heater and will assess the overall techno-economic performance. To do that, the Fraunhofer ISE inhouse dynamic system simulation tools, ColSimCSP and Raytrace3D, will be used. ColSimCSP already provides a standard and validated CSP components library. Within HybridKraft, a validated performance model of an electric heater will be included. All three common CSP (central receiver, parabolic trough and linear Fresnel) technologies will be considered in this project with a focus on Linear Fresnel Collector (LFC) technology with direct use of molten salt by the project partner Frenell GmbH.

Finally, since an ICPH power plant consists of different components (large-scale PV power plant, solar thermal field, molten salt storage, battery storage, power block and electric heater) that will only work together efficiently if they have the right sizing and operation strategy, optimized ICPH power plant concepts including the new heater will be developed and evaluated techno-economically by Fraunhofer ISE. For this, different integration options of the electric heater will be studied, and optimized configurations specific to a CSP technology as well as market conditions will be identified based on simulation studies.