| Duration: | November 2014 - Juni 2015 |

| Contracting Authority/ Sponsors: | ROHM Semiconductor GmbH |

| Project Focus: |

Highly Efficient and Integrated UPS Inverter with SiC Transistors

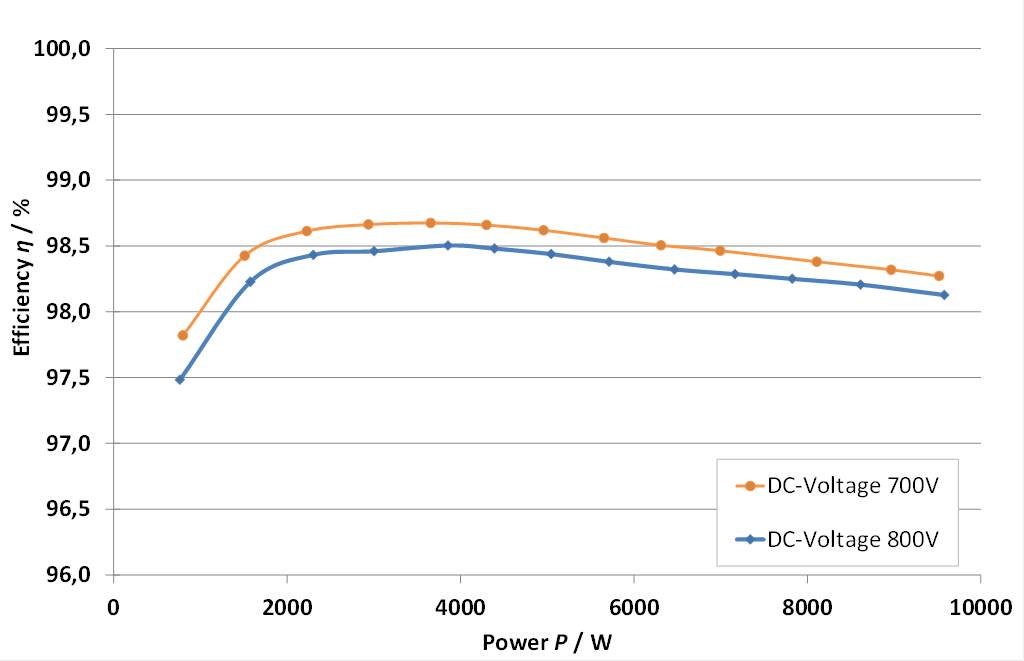

Highly Efficient and Integrated 10 kW UPS Inverter with SiC Transistors, 5 l Volume and a Maximum Efficiency of 98.7 %

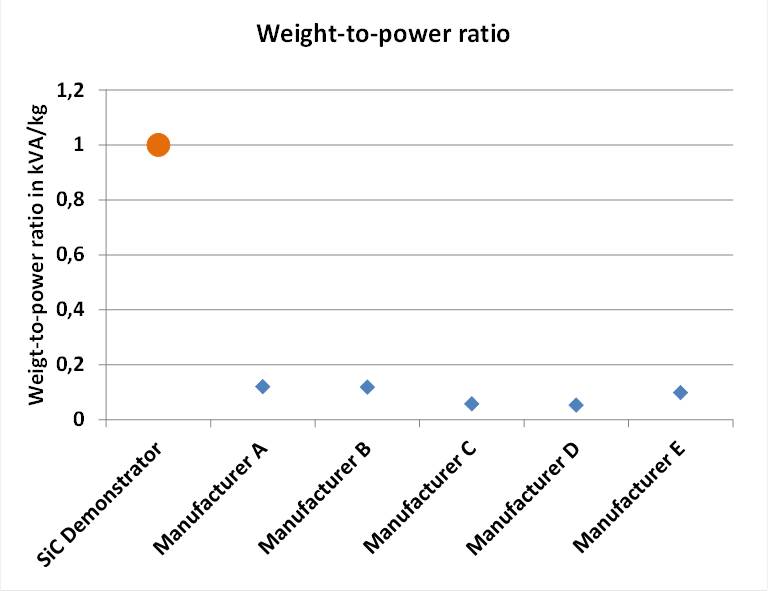

A highly compact inverter has been developed at Fraunhofer ISE for an uninterrupted power supply (UPS) with an efficiency of up to 98.7 %. Using silicon carbide (SiC) transistors, a design with a power of 10 kW and a volume of only 5 l was realized. The degree of efficiency is particularly important for the application in so-called online UPS systems, as they do not only compensate short-term voltage dips in the grid, but also supply the consumer permanently via the UPS. The research and development results can also be applied to other areas of power-electronics energy conversion, where weight and efficiency play a key role.

Using silicon carbide (SiC) transistors, a design with a power of 10 kW and a volume of only 5 l was realized, while maintaining a very high degree of efficiency. The good dynamic and static properties of the transistors enable a frequency of 100 kHz. This frequency is approx. five times higher than for conventional components made of silicon (Si) without a significant increase in the losses in the semiconductors. Subsequently, passive storage components, such as reactors and capacitors could be dimensioned smaller in the system. Due to the reduced losses, a compact cooling system could be used for the transistors. Overall, this saves costs and material at the system level. Furthermore, the degree of efficiency strongly influences the running operating costs in this case in the form of electricity costs. Compared to a conventional system, up to 40 % of the operating costs can be saved by using the new technology. At the system level, the higher costs of the new SiC semiconductors can be compensated by savings in the passive components and the running operating costs. The development intended as technology prototype demonstrates the possibilities of new semiconductor materials, such as SiC. With the future availability of transistors for higher currents, systems with significantly higher power can be realized.