| Duration: | 12/2020 - 02/2026 |

| Contracting Authority/ Sponsors: |

Bundesministerium für Bildung und Forschung (BMBF), Projektträger Jülich, Förderkennzeichen 03SF0619A |

| Project Partners: | AZUR SPACE Solar Power GmbH; HQ-Dielectrics GmbH; Helmholtz Zentrum Berlin; Laytec AG; Plasmetrex GmbH; Sempa Systems GmbH; Technische Universität Ilmenau; Universität Marburg; Universität Ulm; Walter Schottky Institut Technische Universität München; Projekträger Jülich (PTJ) |

| Project Focus: | |

| Website: | h2demo.de |

H2Demo – Development of Demonstrators for Direct Solar Water Splitting

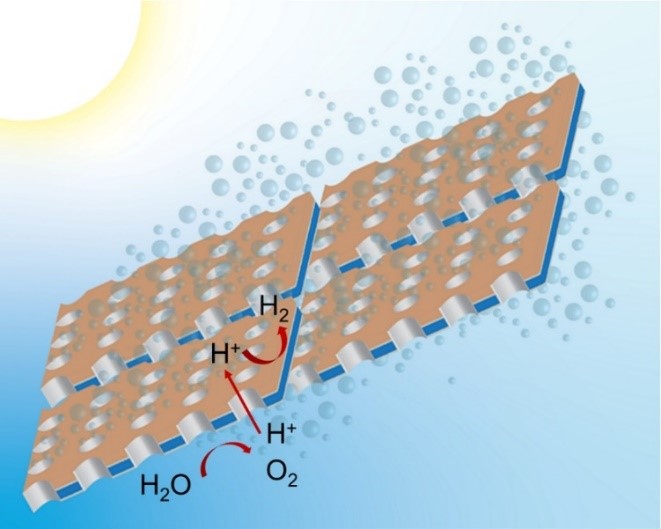

The aim of the H2Demo project is to produce the first large-scale demonstrators for direct solar hydrogen production. This is the absorption of sunlight in a semiconductor structure that generates a sufficiently large photovoltage > 1.6 volts to decompose water directly into hydrogen and oxygen. In the project, particularly promising tandem absorbers made of GaAsP/Si are being developed, which have the best chances of economic viability in combination with high efficiency and scalability. The III-V materials are characterised by very good stability and have already been investigated in detail in the BMBF-funded projects "III-V-Si" and "MehrSi". By directly growing a few micrometres thin III-V layer on silicon, it was possible to produce solar cells that convert 25.9% of the energy of sunlight into electricity - this is an internationally respected world record for this technology [1, 2]. But there is still room for improvement, as the efficiency potential is even higher than 35%.

In the H2Demo project, the GaAsP/Si tandem absorbers are being adapted to the requirements for hydrogen production, and growth conditions as well as the layer structure with its approximately 20 individual layers are being optimised.

In addition, an H2 module concept will be developed on the basis of theoretical simulation calculations. The tandem absorbers are provided with protective layers that prevent corrosion, but at the same time have electronically passivating properties and enable charge exchange. Catalysts are applied to the protective layers, e.g. nanostructured rhodium, or platinum. Using a similar approach and tandem GaInP/GaInAs absorbers, the project partners have already achieved the current efficiency record of 19% for direct photoelectrochemical water splitting in 2018.

Several measures are being taken to scale up and further improve the technology: More economical processes for the production of GaAsP/Si tandem absorber layers are being developed, in particular by optimising growth rate, reactor throughput and gas utilisation in III-V epitaxy. New protective layers are deposited on the absorbers by means of atomic layer deposition ALD. These are thin layers of a few nm, some of which are already used in modern silicon solar cells. For the catalysts, new processes must be developed for homogeneous deposition on large areas. This scaling brings new challenges but is a crucial step in demonstrating the relevance of direct water splitting.

At the end of the project, modules with a size of at least 1300 cm2 and a solar-to-hydrogen conversion efficiency > 15% are targeted. The materials and manufacturing processes will be continuously evaluated for their scalability as well as environmental and economic aspects. The consortium of five companies (three of which are SMEs), four university groups and two non-university research institutions has set itself the task of demonstrating the benefits and potential of direct water splitting at the highest international level.