| Duration: | 01/2025 - 12/2027 |

| Contracting Authority/ Sponsors: | Federal Ministry of Economic Affairs and Climate Action (BMWK) |

| Project Partners: | Bundesministerium für Wirtschaft und Klimaschutz |

| Project Focus: |

GRISU – Holistic, Realistic, Novel Testing Methods and Innovative Fire Protection Measures

in mechanical environmental simulations for the development and verification of electric mobility batteries.

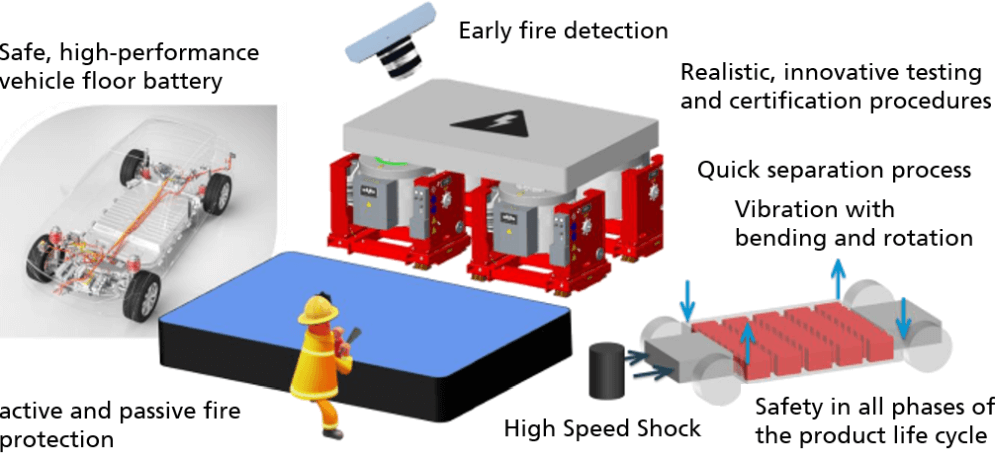

The GRISU project aims to minimize the fire risk of batteries during thermal runaway or thermal propagation in storage systems in order to improve laboratory safety during safety tests. The existing test procedure is being further developed with the aim of more realistically reproducing the mechanical stresses that occur during operation. The bending and torsion that occurs is realized on the test specimen using four decoupled shakers. In addition, potential fire protection methods are tested for their effectiveness in preventing battery fires. The results are incorporated into the development of the shaker system and its laboratory environment. The demonstration takes place in our laboratories at Fraunhofer ISE.

An electric vehicle is subjected to different loads on the axles when driving on the road. This uneven load affects the car chassis in the form of bending and torsion, which are also transferred to the installed battery storage system. Over the service life, such stresses can lead to such damage, which in the worst case can lead to a fire triggered by the storage system. According to the current state of the art, individual or rigidly coupled shaker systems are used to simulate the mechanical loads during vibration tests.

For weight reasons, only single or multiple battery modules – not storage systems – are currently being tested on the shakers on a rigid mounting surface. A frequency range similar to the testing of vehicle chassis is used for excitation for vehicle bodies is also used for excitation. This means that no conclusions can be drawn as to how a battery storage system will bend and twist when the four wheel suspensions are individually excited. Furthermore, the frequency range used is not sufficient to simulate extreme axial loads such as asphalt damage or curb crossing. Moreover, the existing machines do not have any fire protection mechanisms that would allow early separation and extinguishing of the test specimen in a safety-critical condition of the battery. Therefore, there is no standardized protection for the test room, the test equipment, or the laboratory personnel.

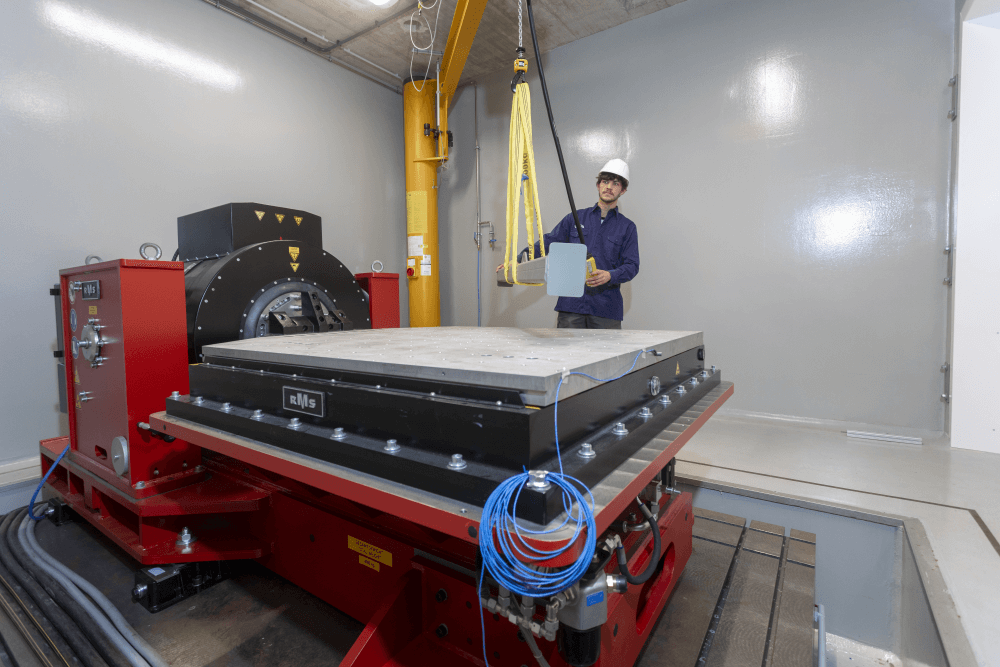

The test device to be developed in the GRISU project will be constructed from four individual shakers in the Battery Testing Lab at Fraunhofer ISE. Each of the shakers will be able to reproduce the loadsof a wheel suspension on the storage system. The four shakers will be controlled and regulated by HAW (Hochschule für angewandte Wissenschaften) Hamburg. Thanks to its extensive testing capabilities, load data is recorded on the basis of field tests on electric vehicles on a wide variety of road surfaces. The findings are used as a basis for developing new test procedures that can simulate the bending and torsion of the battery storage system. The four shakers are coordinated so that they generate the different axle loads separately from each other and do not work in synchronisation, as is the case with conventional shaker systems. This more realistic test setting is a key unique selling point of the test device developed in the project. Due to the new possibility of performing more realistic tests, the risk of a safety incident in the battery increases.

To mitigate this risk, the partner company, Messring GmbH, is developing a universal quick-release device. Their expertise in crash test facility construction and data acquisition will help to separate the equipment attached to the four shakers, including the battery storage system , from the test machine as quickly as possible and without human intervention, and to initiate the extinguishing of the storage unit. In order to trigger the disconnect and deletion process in an emergency, parameters to be defined in the project are required that allow a safety-critical condition to be clearly identified. A suitable deletion concept can then be used to create a controllable situation. For this purpose, fire-retardant tests are being carried out at Fraunhofer ISE in close cooperation with a fire protection expert for lithium-ion batteries under defined laboratory conditions. Furthermore, research is being conducted in collaboration with the partner company Linxens Deutschland GmbH on the early detection of battery fires through gas detection. Sensors will be used to detect the gases released from battery cells in the event of a fire and analyze them in real time. This would make it possible to better recognize threatening scenarios at an early stage and initiate a premature termination of the test as well as the extinguishing process.