| Duration: | March 2013 - March 2018 |

| Contracting Authority/ Sponsors: | German Society for Cooperation (GIZ), Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMUB) |

| Project Partners: | Agence Nationale pour la Maîtrise de l´Energie (ANME), INTER CONTROL S.A, ENERCO, CRA2E |

| Project Focus: |

DAST II TuPro – Dissemination of Innovative Solar-Thermal Applications within Tunisian Industry

Process heat is needed for various production and cleaning purposes specially in the food industry, where process heat takes up a considerable part of the industrial total energy consumption. A number of optimisation measures can contribute to energy and cost reductions. Within the scope of the “DAST II TuPro” project, technical and economic possibilities should be identified at selected Tunisian production locations for the use of solar thermal technology and a foundation laid for the establishment of an energy management system. First, energy efficiency potentials are checked and their implementation chances evaluated. The selected companies operate in the food & beverages industry. A high portion of necessary process heat is typical for this industry. Systematic energy management is used to continuously increase the energy efficiency, mainly in energy-intensive companies.

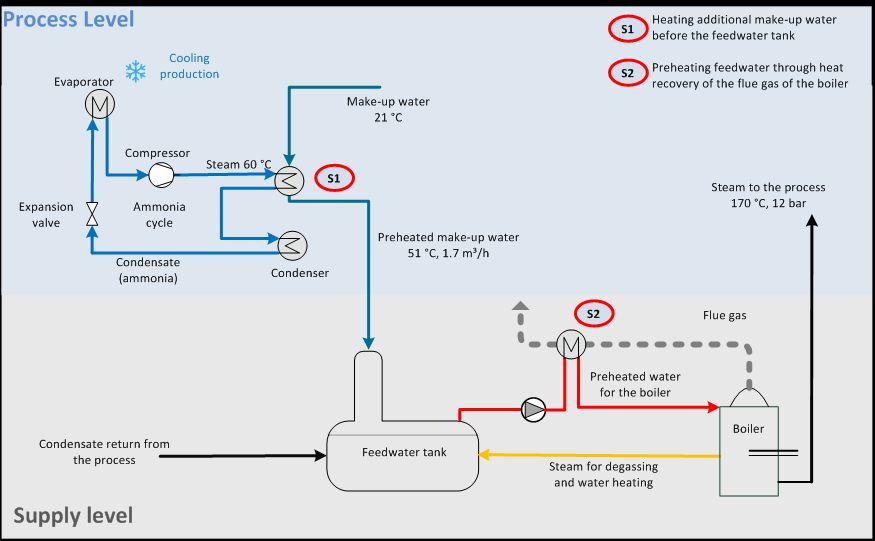

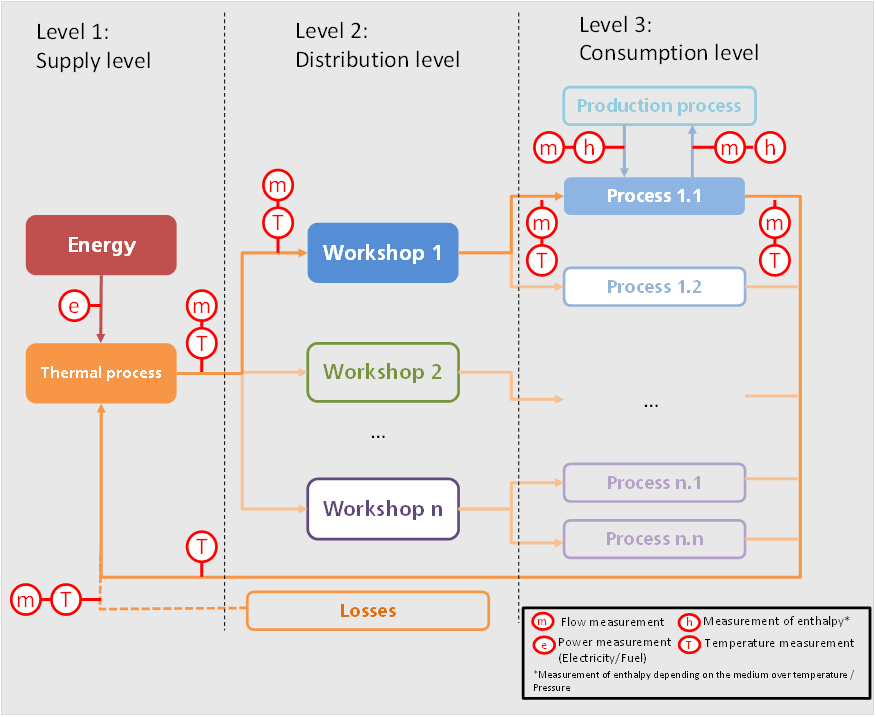

To increase the energy efficiency, the essential energy flow in the participating companies were characterized and quantified first using already existing measuring technology and mobile measuring equipment provided by Fraunhofer ISE to capture the energetic actual state. Already existing plant diagrams were updated during plant inspections and necessary data added. Cost-effective measures to be executed were already decided on in an early stage of the project in close collaboration with the plant operators. This measures can be seen schematically in Fig. 1. The processes were divided into different levels to introduce a standardized energy monitoring system as further energy management component (Fig. 2). This way, measuring points can be defined in the processes, where energy flows can be captured and analyzed for energy monitoring to identify further saving potentials.

The execution of energy efficiency measures, the installation of the energy management system and of the required measuring technology are supported by Fraunhofer ISE through instructions to the executing Tunisian companies. Fraunhofer ISE advises at least one local partner regarding monitoring execution, regarding the creation of a measuring concept and the selection of the required measuring technology, sensor calibration, fault detection, and remote data inquiry.