Press Release #22

Fraunhofer ISE Supports Energy-Intensive Industries in Identifying Energy-Saving Potential

German industrial companies are currently suffering from the sharp rise in the cost of fossil fuels and electricity. Such massive price increases are a looming threat to the existence of energy-intensive industries. As a result, saving energy is becoming a key issue for companies. The Fraunhofer Institute for Solar Ener-gy Systems ISE makes use of its expertise to help companies decrease the ener-gy consumption at their sites, and thus lower costs and reduce greenhouse gas emissions. A key success factor here is Fraunhofer ISE’s holistic consideration of the production processes and energy flows, as a current project with a company from the corrugated cardboard industry shows.

Currently the sector with the highest natural gas consumption in Germany is the industry, with a share of 35 percent. "Against the backdrop of the sharp increase in prices and even a looming natural gas outage, many industries are currently looking for alternatives and more efficient production processes. Moreover, competitive advantages for the industrial sector are greener products and a successful certification according to the Environment, Social and Governance rating criteria," explains Dr. Thomas Fluri, group leader of Solar Thermal Power Plants and High Temperature Storage at Fraunhofer ISE. "With our interdisciplinary approach, we assist energy-intensive companies in reducing the energy consumption of their facilities."

For this, all processes are considered in a holistic manner, in which Fraunhofer ISE applies its broad expertise from component development, solar thermal, photovoltaic and storage systems through to energy data analysis and decarbonization of industrial processes. In the first step, the project team collects comprehensive energy data at the site and develops innovative monitoring concepts. The measured data are then evaluated and appropriate energy-saving measures are developed.

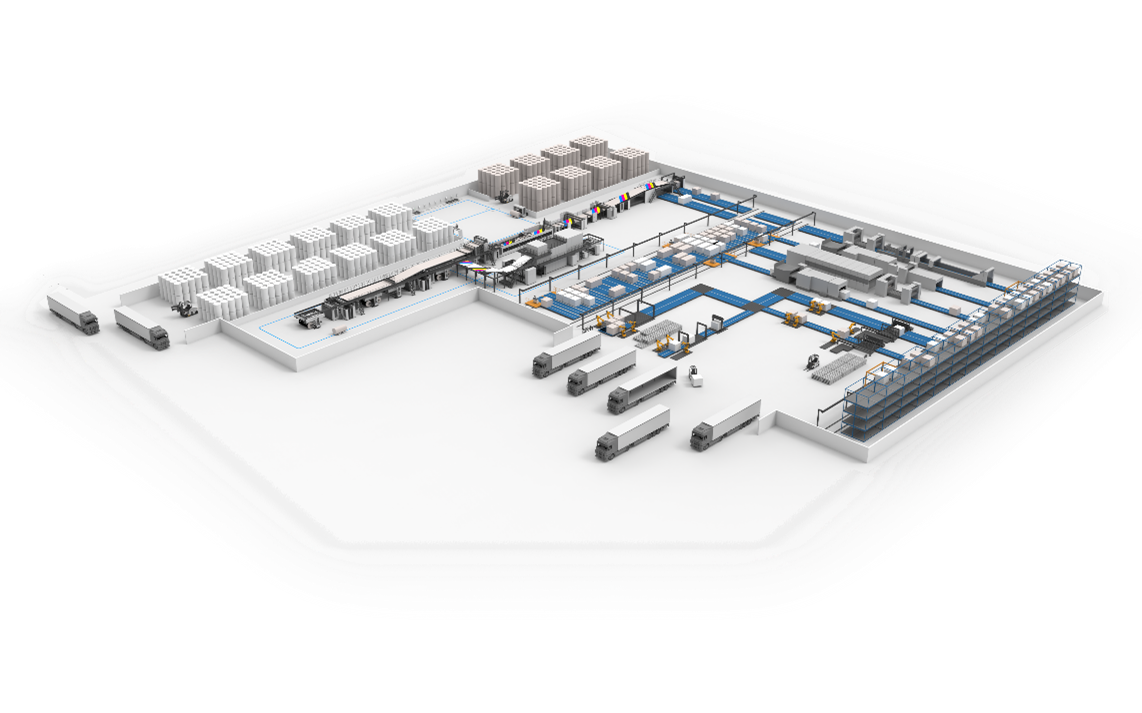

Potential Study on Energy-Efficient Corrugator in Cooperation with BHS Corrugated

Corrugated cardboard is one of the most important packaging materials in the world. One of the largest solution providers in the corrugated board industry is BHS Corrugated GmbH with headquarters in Weiherhammer, Germany. More than 50,000 soccer fields could be covered with the annual corrugated board production of a corrugator, designed by BHS Corrugated. On behalf of BHS Corrugated, Fraunhofer ISE developed energy saving measures with the aim of reducing heat and electricity consumption.

The Analysis

An energy monitoring system was installed at a corrugated board production plant site of a BHS customer to determine the energy data of the various plant components and process steps. Based on the data obtained, the research team analyzed the existing systems for their energy saving potential. The focus of the analysis was on the steam heating system used, which is the primary energy source for the corrugator. Alternative heating systems were identified and evaluated with respect to their energy efficiency and the potential cost savings. Process integration and feasibility were considered. The use of photovoltaics and storage systems to reduce CO2 emissions was also reviewed.

Annual Savings Potential of up to 720 tons of CO2

Based solely on the various energy provision measures recommended for the analyzed production facility, a savings potential of 4.5 kilograms CO2 per 1000 square meters of produced corrugated board was determined. Considering the plant's production capacity of around 160 million square meters, this results in an annual potential CO2 savings of 720 metric tons. (By comparison, world production of corrugated board is estimated at 260 billion square meters annually.) Additionally, the installation of a photovoltaic system (820 kW) would reduce the production facility’s electricity bill by almost 150,000 euros per year and cover 14 percent of its electricity demand, in addition to providing protection against future increases in electricity price. Installation of a battery storage could be used to cap peak loads. In addition to increasing the share of renewables in the power supply, the use of renewables in the heat supply, such as solar thermal energy utilization, also contribute to decarbonization. "Often, the goals of higher plant productivity and responsible use of resources go hand in hand. One example is the reduction of energy costs by reducing the use of paper – a synergy effect that reduces costs as well as emissions. The project with the Fraunhofer ISE research team has laid a promising foundation for the future by demonstrating possibilities for improving productivity and sustainability through the use of corrugators from BHS Corrugated," says Dr. Berthold Aumüller, Manager Innovation Management& Research at BHS Corrugated.

Fraunhofer ISE also sees great potential for reducing energy consumption in other industries. Of particular interest are the textile, food, paper and chemical industries, since low-temperature steam is used in many processes, such as drying paper products, sterilizing and pasteurizing food, or distillation processes." We estimate that the demand for process heat up to 480 degrees Celsius is about 159 terawatt-hours in Germany. We see great potential here for reducing energy consumption and switching to alternative technologies for heat and power generation," says Dr. Thomas Fluri.

About BHS Corrugated Maschinen- und Anlagenbau GmbH

BHS Corrugated Maschinen- und Anlagenbau GmbH is the leading provider in the corrugated industry with more than 3,000 employees at its headquarters in Weiherhammer, Germany and in more than 20 countries worldwide. As a lifecycle partner, BHS Corrugated is consistently strong across the entire product and service range: from development and production, installation and maintenance, to a variety of innovative service solutions in the areas of corrugating rolls, individual machines, complete corrugators, Industry 4.0, logistics, and, soon to come, inline digital printing. In order to meet our customers’ requirements as precisely as possible and always be at the cutting edge of technology, BHS Corrugated reinvests nearly five percent of its sales in research and development. In addition to its core business, BHS Corrugated supports various social projects, such as the family foundation "Angels for Children" (AFC) or the "Lars and Christian Engel Foundation (LUCE)", which is committed to promoting technological and economic development in the region.

Last modified: