Press Release #22

European Glass-Glass Photovoltaic Modules Are Particularly Climate-Friendly

In a new study, researchers at the Fraunhofer Institute for Solar Energy Systems ISE have calculated that silicon photovoltaic modules manufactured in the European Union produce 40 percent less CO2 than modules manufactured in China. Using a life cycle analysis (LCA), the research team compared the CO2 footprint of monocrystalline solar modules manufactured in Germany, Europe and China. In the process, they also found that glass-glass modules enable an additional emissions reduction ranging between 7.5 to 12.5 percent compared to PV modules with backsheet films, regardless of their production location.

Although photovoltaic modules convert sunlight into electricity without producing emissions, PV-generated solar energy does produce CO2 emissions during production, transport and at the end of module life. These emissions are, however, very low: About 40 times less CO2 is produced per kilowatt-hour with PV electricity than with electricity generated by lignite. In the study, Fraunhofer ISE calculated the CO2 footprint of six monocrystalline silicon photovoltaic modules. Modules manufactured in China, Germany and the European Union, as well as a module with glass-foil laminate and one with glass-glass laminate were investigated.

Electricity Mix of Countries Has the Greatest Influence on the CO2 Footprint

"If I want to install a photovoltaic system in a European location with average irradiation values, I have a great influence on its climate friendliness with the choice of my PV modules," explains Dr. Holger Neuhaus, Head of Department for Module Technology at Fraunhofer ISE. "With PV modules manufactured in the EU, I save 40 percent in CO2 emissions compared to modules imported from China."

This is mainly due to the energy mix of the respective countries and less to the emissions generated during transport. At 50 to 63 percent, the share of energy required in manufacturing is the most influential factor on the CO2 footprint of a solar module. For a PV module from China, the CO2 emissions generated during transport to the EU account for about 3 percent of the total emissions.

"Due to the significantly lower CO2 emissions during production and the further strong increase in demand for more climate-friendly PV modules worldwide, it is now a matter of establishing the PV production chain in Europe quickly and with a great deal of commitment," concludes Prof. Andreas Bett, Institute Director at Fraunhofer ISE. China has a dominant market position: In 2019, China produced 68 percent of the polysilicon, 96 percent of all wafers, 76 percent of all solar cells and 71 percent of all PV modules.

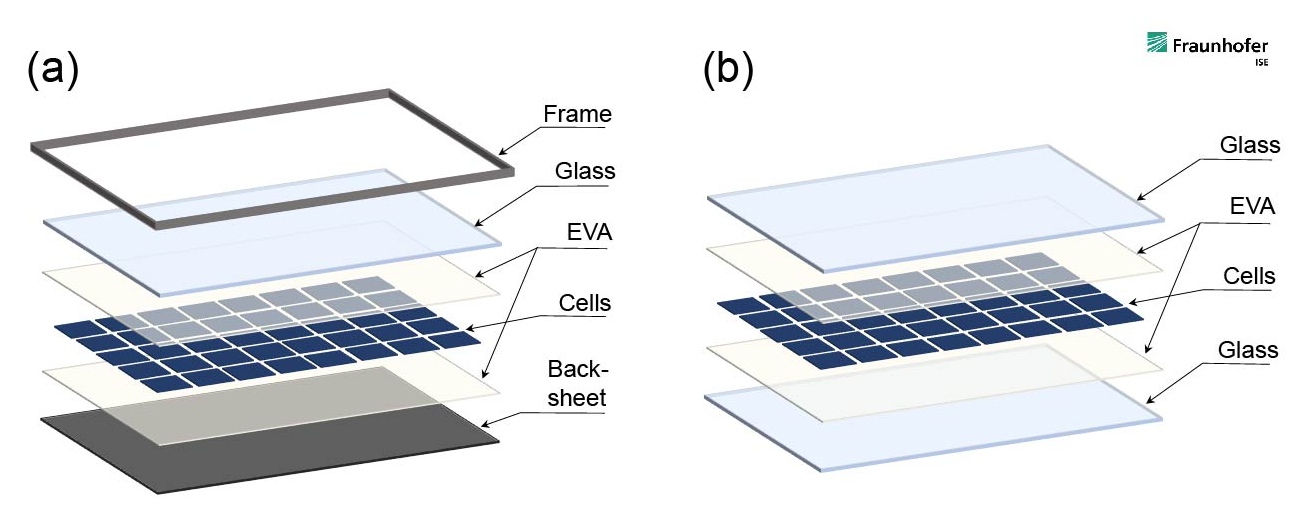

Module Designs with Glass Instead of Back Foils Reduce CO2 Emissions

Frameless glass-glass modules additionally cause 7.5 to 12.5 percent less CO2 during production than glass-foil modules. This result was shown in the study for all modules examined, regardless of the manufacturing location. The reason for this is not the backsheet itself, but the fact that glass-glass modules do not require an aluminum frame, which is a very energy-intensive to produce. Glass-glass modules also have a longer lifetime and lower annual degradation than modules with a film, which further improves their carbon footprint. In terms of kilowatt hours generated, frameless glass-glass modules produce 22 to 27 percent less CO2 emissions than glass-foil modules. Unfortunately, only a few manufacturers opt for frameless glass-glass modules.

Overall, the study results show that the CO2 emissions for glass-foil modules (glass-glass modules) are 810 (750) in China, 580 (520) in Germany and 480 (420) kilograms of CO2 equivalent per kilowatt peak in the European Union. The study is based on new production data collected at the institute in collaboration with industry. "This is the real news. Compared to life cycle analyses based on older data sets that are still used today, the study showed that the carbon footprint of PV modules has improved by about 80 percent in recent years. This is due to improvements in the silicon yield, the manufacturing processes of module efficiency and the CO2 intensity of power generation," explains Dr. Holger Neuhaus.

Further research at Fraunhofer ISE on the CO2 footprint of PV modules:

· S. Riepe, S. Nold, P. Brailovsky, P. Krenckel, L. Friedrich, S. Janz, R. Preu, CAST-MONO SILICON WAFERS FOR A SUSTAINABLE PV MARKET GROWTH, Proceedings of the 37th EUPVSEC (2020)

· S. Herceg, A. Briem, M. Fischer, P. Brailovsky, T. Dannenberg, M. Held, A COMPARATIVE LIFE CYCLE ASSESSMENT OF PV MODULES – INFLUENCE OF DATABASE AND BACKGROUND SYSTEM, Proceedings of the 38th EUPVSEC (2021)

· M. Salibi, F. Schönberger, Q. Makolli, E. Bousi, S. Almajali, L. Friedrich, ENERGY PAYBACK TIME OF PHOTOVOLTAIC ELECTRICITY GENERATED BY PASSIVATED EMITTER AND REAR CELL (PERC) SOLAR MODULES: A NOVEL METHODOLOGY PROPOSAL, Proceedings of the 38th EUPVSEC (2021)

· P. Brailovsky, L. Friedrich, S. Nold, S. Riepe, J. Rentsch, Sustainable PV manufacturing solutions for relaunching the European PV manufacturing industry, PV International 46 (2021)

· L. Friedrich, S. Nold, A. Müller, J. Rentsch, R. Preu, Global Warming Potential and Energy-Payback Time Analysis of Photovoltaic Electricity by Passivated Emitter and Rear Cell (PERC) Solar Modules, accepted for publication, to be published 2021

Last modified: