Press Release #28

Fraunhofer ISE Develops Solutions for Optimized Water Use in Solar Thermal Power Plants

Minimizing the water consumption of Solar Thermal Power (CSP) plants is an important issue, as this kind of solar power generation is often found in arid areas where the solar irradiation is high. Since these regions are also dusty, the associated yield reduction due to local dust deposition and the costs of cleaning are relevant factors. Particularly in regions lacking water, innovative water saving solutions for cooling and mirror cleaning are needed to significantly reduce the water consumption of solar thermal power plants. Any conflict of water use should be avoided to allow high acceptance of the technology. In the MinWaterCSP project, the Fraunhofer Institute for Solar Energy Systems ISE worked together with its partners on several approaches to reduce the water consumption in CSP plants.

ColSimCSP, CSP Simulation Software

The simulation tool for the dynamic simulation of thermal processes, including CSP, has been employed in many research projects as the main tool for system simulation and optimization. Within the MinWaterCSP project, ColSimCSP has been further developed by Fraunhofer ISE, now allowing water and wastewater flows in CSP plants to be comprehensively modeled. Not only the water demand itself but also the water quality (Total Dissolved Solids – TDS), and the energy required to supply and treat the water have been added to the tool.

Furthermore, detailed performance models for wet cooling, dry cooling and hybrid dry/wet systems were integrated into the tool. »The developed simulation tools can now be used for different purposes such as water consumption estimations during site evaluation, cooling system technology selection and optimization, predictive maintenance and the evaluation of plant water balances and quality«, explains Dr. Tom Fluri, Head of Group Solar Thermal Power Plants and High Temperature Storage at Fraunhofer ISE.

Improved internal water management

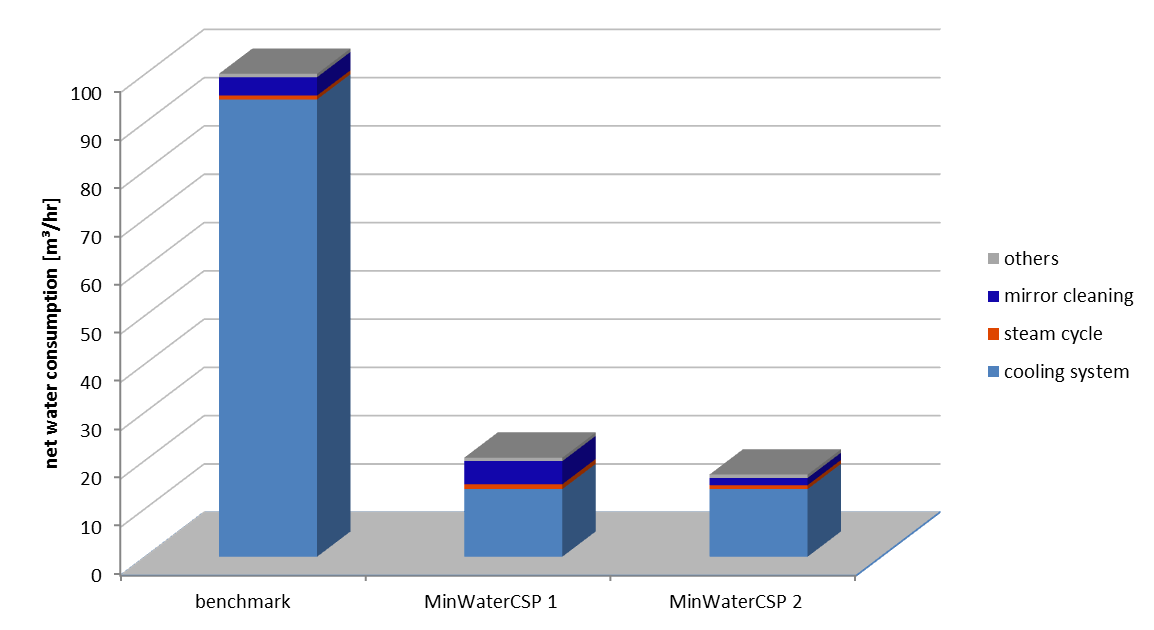

The internal water management of the CSP plant is decisive for water conservation. »The change from wet to dry cooling or to hybrid cooling systems is the most important and efficient measure to save water«, says Fluri. The proposed MinWaterCSP water management approach substitutes the wet cooling tower by a hybrid cooling system: the use of both air cooling and evaporative cooling achieves the desired cooling capacity while reducing water consumption by 85%. The next important change is to use the blowdown water from the cooling system and the steam cycle for producing demineralized water. The resulting internal reuse accounts for up to 36% of the overall water intake. The last important water saving measure is to reduce the amount of losses in mirror cleaning by recollecting water after the mirrors have been wetted for cleaning. According to the steady state mass balances, these measures result in savings of 85%, mainly through the substitution of the cooling system. The suggested reuse loops account for another 28% savings compared to a system without any reuse. With regard to the evaporation pond which is usually part of the water treatment in CSP plants, the suggested concept results in a reduction of capacity from approximately 20 m³/hr to 0.7 m³/hr.

Together with the MinWaterCSP partner company Waterleau, researchers at Fraunhofer ISE analyzed the typical water demand for CSP plants and identified a benchmark. The research group then developed improved scenarios for the water management, using simplified flow charts and the mass balance for water and salts.

Soiling Monitoring and Mirror Cleaning Optimization

Fraunhofer ISE develops equipment and methods for monitoring of soiling and cleanliness. This allows to optimize the performance of power plant operations and cleaning cycles. Methods based on optical measurements characterize the soiling as a function of time and its spatial resolution in the solar field reliably and accurately. Within the project MinWaterCSP, Fraunhofer ISE developed an instrument for monitoring of the collector cleanliness and soiling in the solar field. The instrument can be integrated into a vehicle or truck. Future developments will enable large-area detection of soiling across the solar field. Additionally, Fraunhofer ISE measured soiling in the solar power plant with the mobile reflectometer pFlex, developed by Fraunhofer ISE and now commercialized by PSE AG. Soiling monitoring data in combination with meteorological data, power plant operation data allows for optimization of cleaning and reduction of water consumption. »Looking at the new, high efficiency cleaning truck developed by our partner Ecilimp and taking into account soiling monitoring data and cleaning strategies, we could show that water consumption for cleaning can be reduced by up to 20% and cleaning costs by more than 17% when optimizing cleaning operating strategies«, says Anna Heimsath, Head of Group Concentrating Collectors and Optics.

About MinWaterCSP

MinWaterCSP is a research and development project which aims at reducing water consumption and improving thermal cycle efficiencies of Concentrated Solar Power (CSP) plants. It has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 654443. The project started in January 2016 and will be completed in December 2018.

The MinWaterCSP project consortium consists of 13 partners from 6 different EU and non-EU countries. It is coordinated by Kelvion Holding GmbH (Project Coordinator, Germany) and ENEXIO Management GmbH (Technical Coordinator, Germany). Further partners of the consortiums are: Kelvion Thermal Solutions (Pty) Ltd. (South Africa), Fraunhofer ISE (Germany), Sapienza University of Rome (Italy), ECILIMP Termosolar SL (Spain), Stellenbosch University (South Africa), Notus Fan Engineering ( South Africa), Laterizi Gambettola SRL- SOLTIGUA (Italy), ENEXIO Germany GmbH (Germany), Institut de Recherches en Energie Solaire et Energie Nouvelles- IRESEN (Morocco), Steinbeis 2i GmbH (Germany) and Waterleau Group NV (Belgium).

The project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 654443.

Downloads

Last modified: