Tower-based systems represent a promising technological approach for solar thermal power plants. Up to 50 % of the investment costs for such systems are caused by the heliostat array, which concentrates the incident solar radiation onto a receiver in the tower. High optical quality of the heliostats and their accurate tracking are decisive for the power plant efficiency and the resulting levelized cost of electricity.

Digitalization Transforms Operation of Solar Power Towers

Solar Thermal Power Plants and Industrial Processes

The increasing digitalization of solar thermal power plants enables the potential for efficiency to be better exploited and technical challenges to be overcome successfully. Our research approaches lead to the production and control of the heliostat array being linked to the most modern information and communications technology.

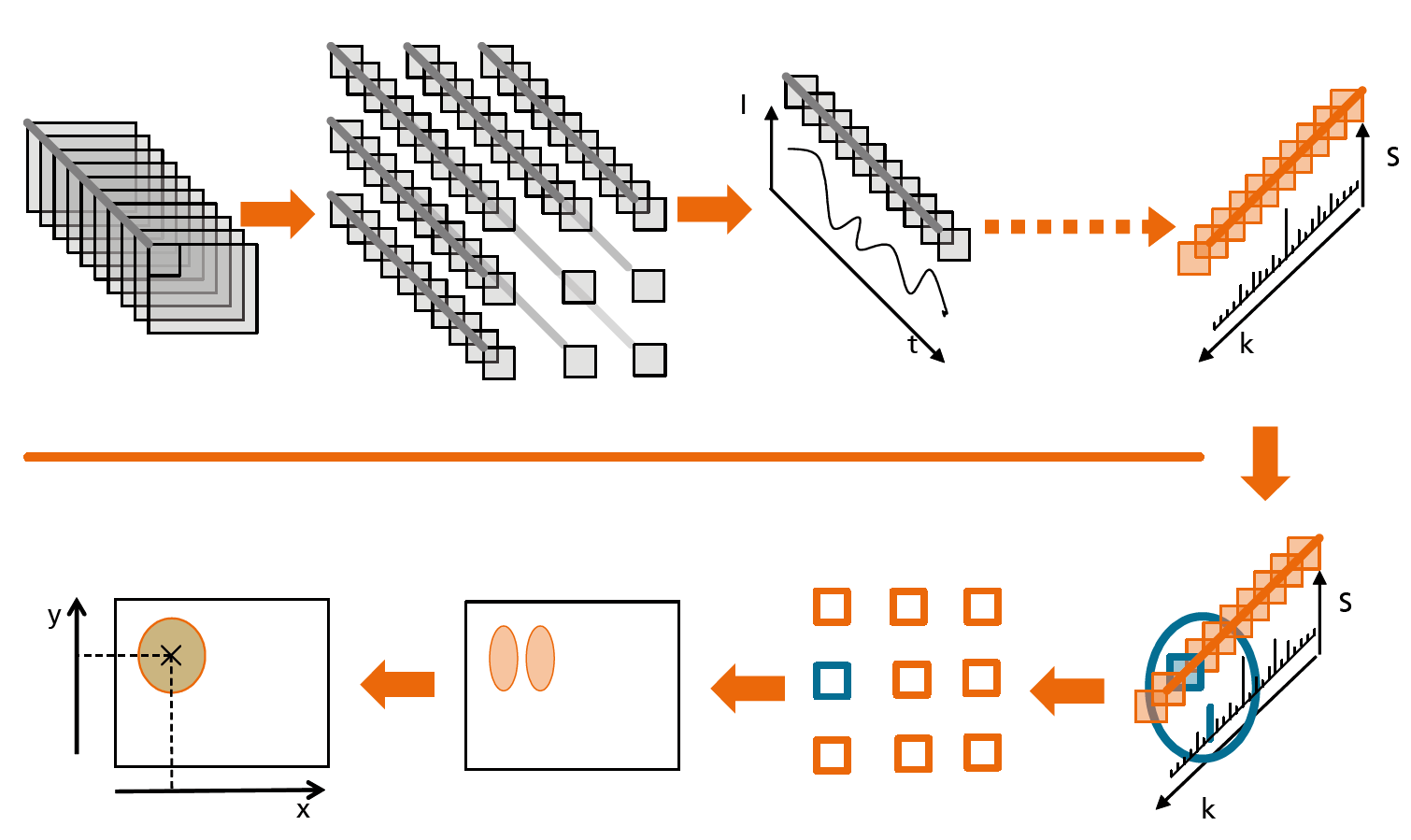

For example, we have developed the »HelioControl« imaging control system to accurately check the actual target positions of heliostats during operation. In addition to their solar tracking, individual heliostats are subjected to periodic motion with a very small amplitude, which is recorded in the accumulated focal spot on the radiation receiver by cameras and then digitally analyzed. The real target point of the heliostats is thus determined and – if this deviates from the intended target position as recorded in the control algorithms – used to correct the corresponding heliostat’s orientation.

The methodology was tested and demonstrated both on a laboratory scale and in initial field tests with a real heliostat array. Compared to the sequential »calibration« of the heliostat target positions on a separate optical target area, which is customary today, the time and expense needed for controlling the target positions of thousands of heliostats in a large array are reduced significantly. In simulation, we could determine appreciable savings, because the improved target control means that fewer heliostats must be installed to achieve the same power. We hope that further savings can be achieved in the heliostat construction itself, as the quasi-continuous target control means that very accurate operation is still possible even if the tolerances on construction are relaxed slightly.

In the next step, we will cooperate with industry to develop a plug-in system that should make the integration into new and existing heliostat array controls feasible. A further application opportunity for »HelioControl« is the initial calibration of a new solar array during its commissioning. Usage of »HelioControl« could reduce the time needed by a factor of a hundred.