| Duration: | 07/2017 - 12/2019 |

| Contracting Authority/ Sponsors: | Federal Ministry for Economic Affairs and Energy (BMWi) |

| Project Focus: |

HelioControl – Development of a Camera-Based Calibration and Control System with Closed Control Circuit for Heliostat Fields

The central receiver system is a technology for solar thermal power generation which is currently being focussed on in research and CSP market.

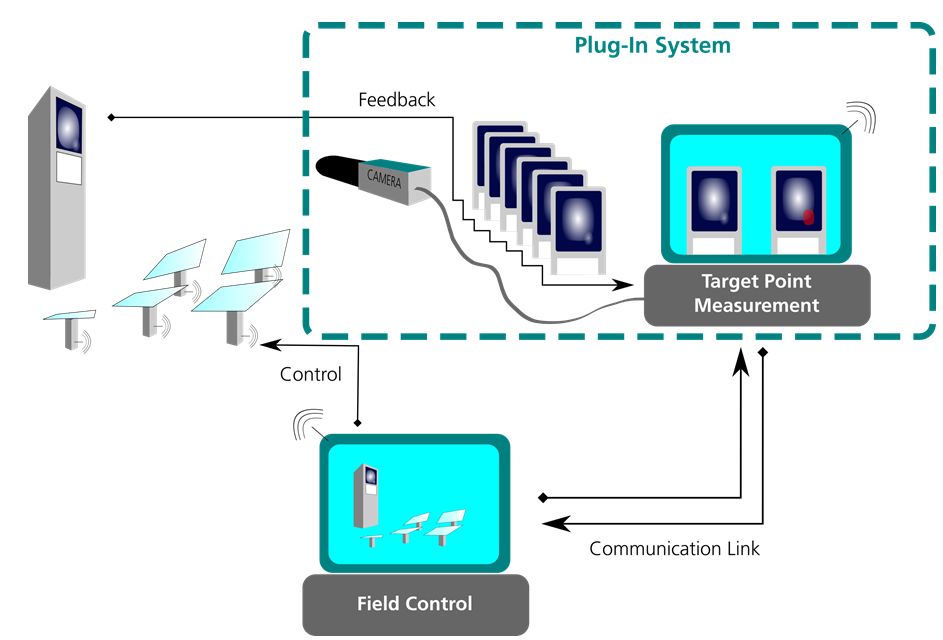

The central aim of the project is the development of a camera-based control system (“HelioControl”) and a control strategy with a closed-loop. HelioControl optimizes and monitors aim point strategies for tracking heliostats in solar tower systems. For the first time, this project enables a closed-loop control in which the actual location of the reflected solar radiation on the receiver of the tower power plant is registered during operation. With the concept at hand, the calibration and control system for heliostat fields - pre-developed during the “HelioPack” project supported by BMWi - will be further developed so that the technology can evolve into a plug-in system for commercial use.

Heliostats concentrate solar radiation on a central receiver. Generally, the heliostats are aligned and tracked via a control which defines the target position for the drives based on a sun position algorithm. However, during actual operation, it is not certain if there are deviations between target and actual coordinates of the target points and how significant such deviations may be. A monitoring of the individual aim points of the heliostats on the receiver in power plant operation allows for the introduction of a closed control circuit with significant potential.

The monitoring of the heliostat aim points and a following correction of the control parameters reduce the requirements for the intrinsic precision of the drives as well as the backlash in the transmission of the gears. Consequently a cost reduction potential in the solar field is addressed.

The information derived is applied to operating strategies of the central receiver system. Currently the temperatures achieved in the central receiver systems are restricted by the material properties of the receiver. Temperature limits must be met to prevent power plant failure due to overheating of the receiver. Especially hot spots, local regions with excess temperature, may cause serious damages. With the state of the art, the control of such is limited.

An optimal flux density distribution at the receiver corresponds to a homogenous distribution at the aperture, adjusted to the rate of flow of the heat transfer fluid and with minimized losses on the edge. A homogenous distribution without hot spots allows reduced safety margin to the maximum temperatures and thereby increases the service life as well as thermal efficiency of the receiver.

These aspects are addressed through an in-situ monitoring of the actual aim points during operation and through the adjustment of the flux distribution at the receiver. The homogeneity is optimized on the basis of this data and the described hot spots can be avoided. This allows for safer operation at increased temperatures compared to the current state of technology.

The results of a measurement campaign within the SFERAII Access program at the French solar tower plant Themis (PROMES-CNRS) were presented at the SolarPACES Conference 2019 in Daegu, South Korea. (Presentation | Publication). To evaluate the radiation information at the cavity receiver of the test facility, a correction model of the reflection properties was created from measurement data. This can compensate for the highly variable reflection differences caused by radiation shielding plates and the rear wall of the test receiver. Such reflectivity variabilities are unlikely in commercial power plants. For the future measurement of the reflection properties, a method was developed which allows the measurement of the reflectance from the heliostat field.