Fraunhofer ISE focuses on the development of new materials for sensible and latent heat and cold storage and has an extensive R&D infrastructure and many years of experience in this field. The aim of our research is in particular to increase the storage density and long-term stability of the storage materials. In addition, we analyze the interactions between tower packings, heat transfer fluid and tank or capsule materials. In addition to sensible and latent heat storage materials, we also develop and optimize sorption materials.

Our R&D services include:

- Material screening of heat storage and insulation materials

- Characterization of thermophysical material properties such as specific heat capacity, heat of fusion and phase transition temperatures, enthalpy of reaction of sorption materials, viscosity, density, thermal diffusivity and thermal conductivity

- Investigation of thermal stability, flash point and chemical composition

- Investigation of outgassing and gas atmospheres in the storage tank

- Tests on the long-term stability and compatibility of storage materials, tower packings, working fluid and storage components

- Development of formulations for the production of PCM emulsions (PCM slurries) on a liter scale and upscaling of production to a cubic meter scale

- Determination of the crystal structure (XRD), phase analysis and conversion of sorption materials

- Thermal stabilization of PCM

- Testing and characterization of PCM and PCM composite materials for the RAL-PCM seal of approval

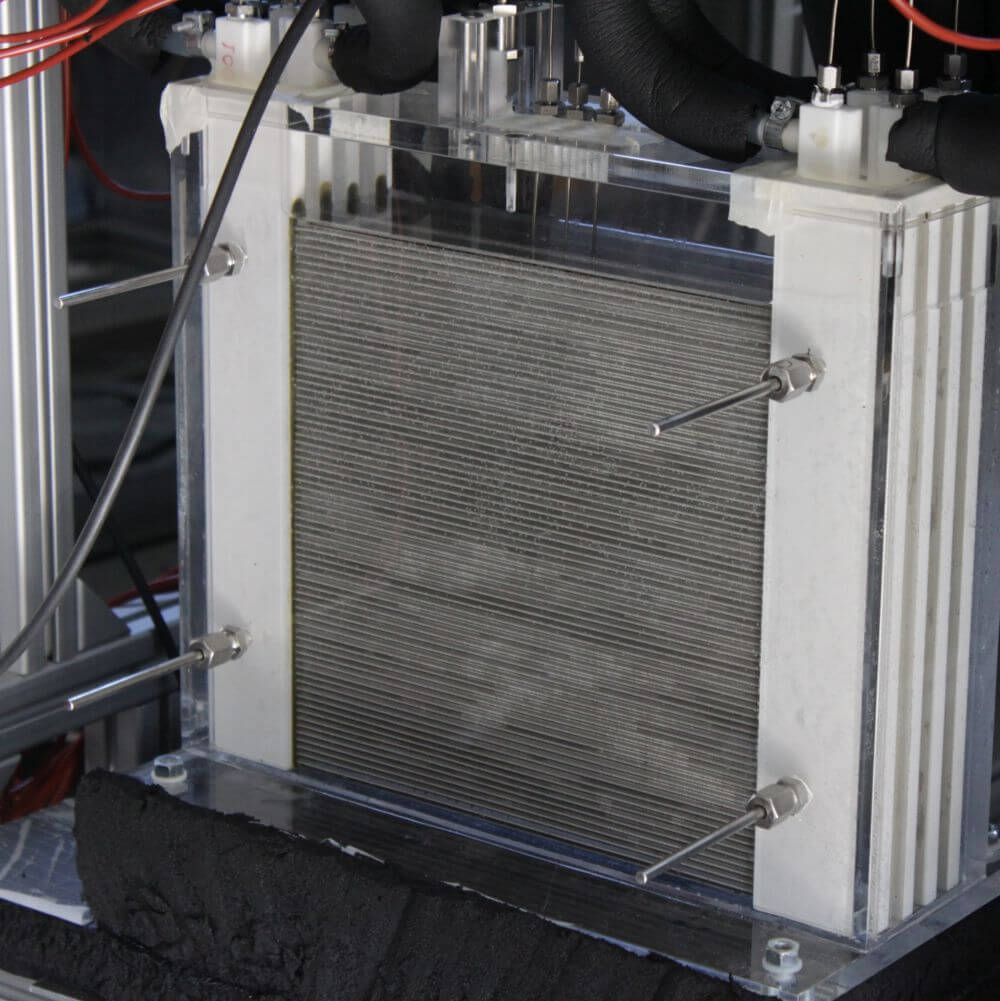

Fraunhofer ISE has particularly broad expertise in the development of PCM slurries. These are high-performance heat transfer fluids that make it possible to reduce the required storage volume due to the high heat capacity of the fluid. We disperse organic PCMs in water or water-glycol mixtures to produce a heat transfer fluid that has up to four times the storage density of water in the melting range of the PCM. We are also working on oil-water emulsions for temperature ranges below 0 °C.

We are developing composite materials for use in buildings as well as for technical applications, e.g. for battery and electronics cooling. Microencapsulated PCM can be finely distributed in the composite material and a large surface area can be created between the composite material and the PCM, which is conducive to rapid charging and discharging.

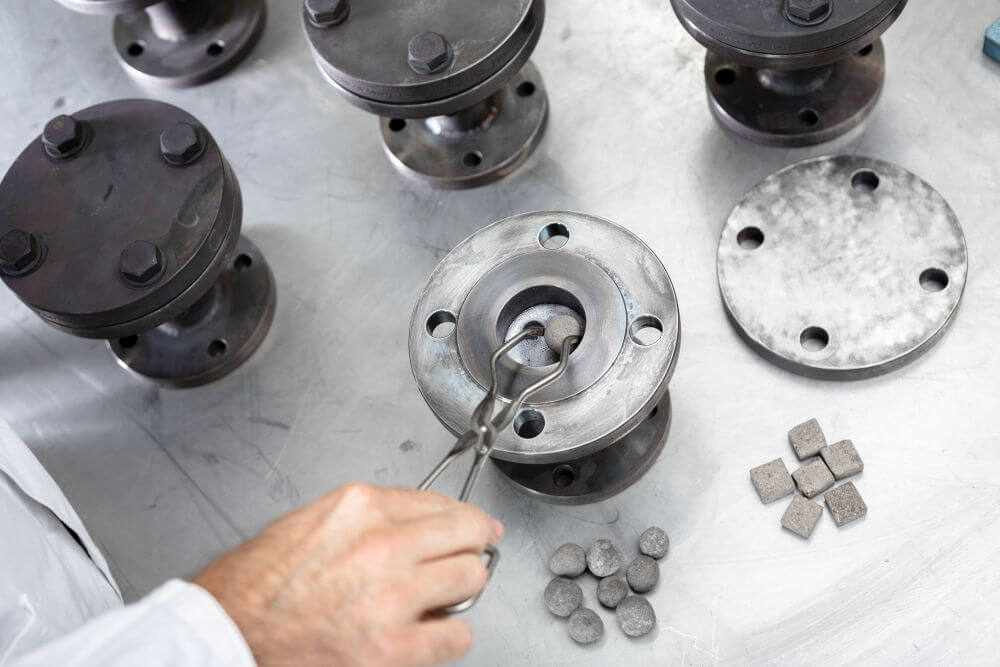

In the field of high-temperature storage systems, we have many years of experience in the development of sensible molten salt storage systems based on nitrate salts, which are used on an industrial scale in solar thermal power plants. We also support project partners in the development of storage systems based on water, thermal oil, metal alloys and ceramic solids.

We measure and evaluate the various storage technologies in our laboratories and outdoor test sites around Freiburg or in demonstration plants directly in the application.