| Duration: | 05/2021 - 04/2026 |

| Contracting Authority/ Sponsors: | Federal Ministry of Economic Affairs and Climate Action (BMWK) |

| Project Partners: | H&R Wax & Specialties GmbH, Hochschule RheinMain, Konvekta AG, IKS Industrielle KühlSysteme GmbH |

| Project Focus: |

Optimus – Development, Optimization and Application of PCM Emulsions with High Thermal Storage Density

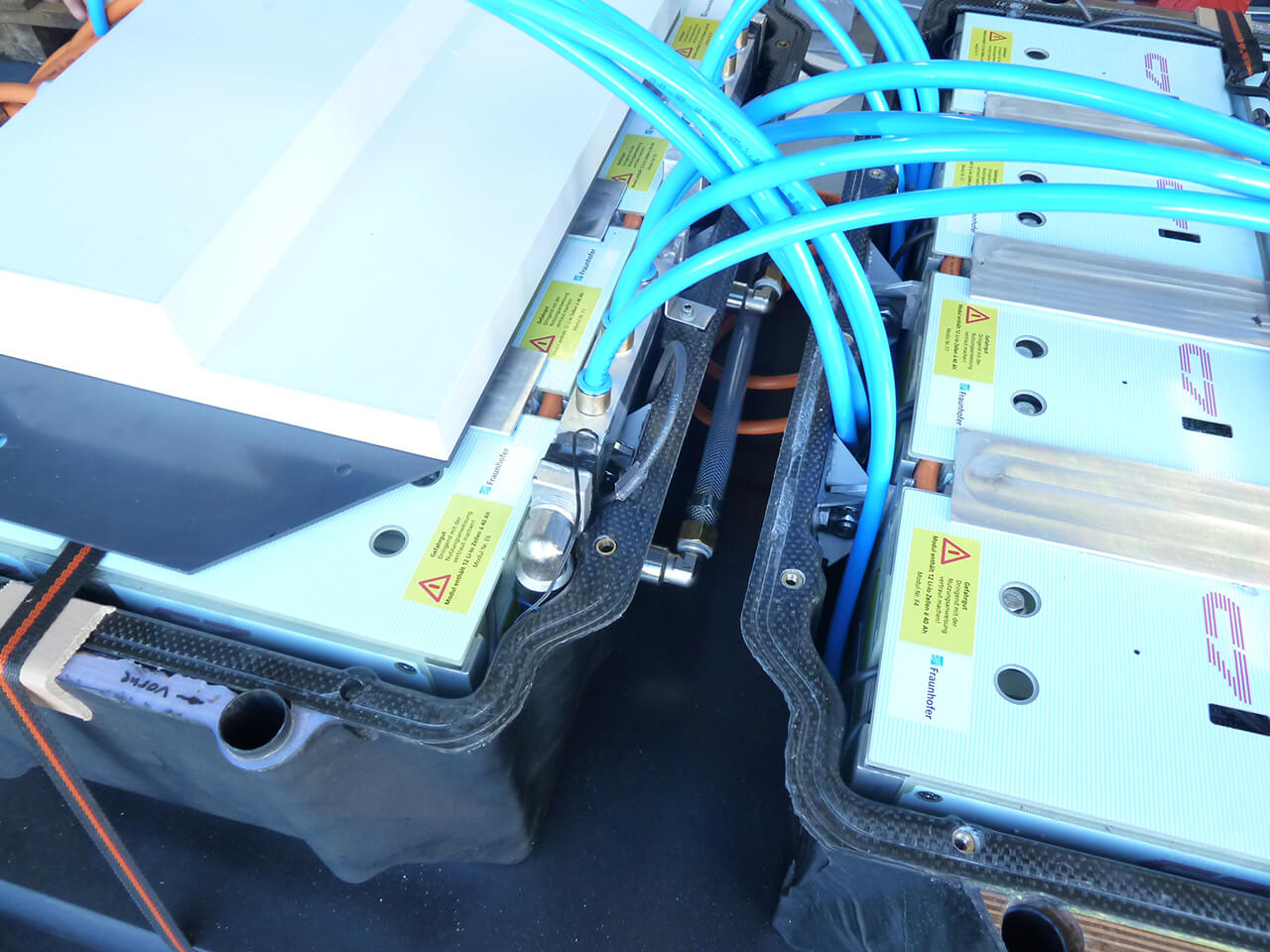

In the "Optimus" project, we are working with industrial partners to develop new emulsions of phase change materials (PCMs) for use in buildings and industry, as well as for heat pump systems and battery cooling in motor vehicles.

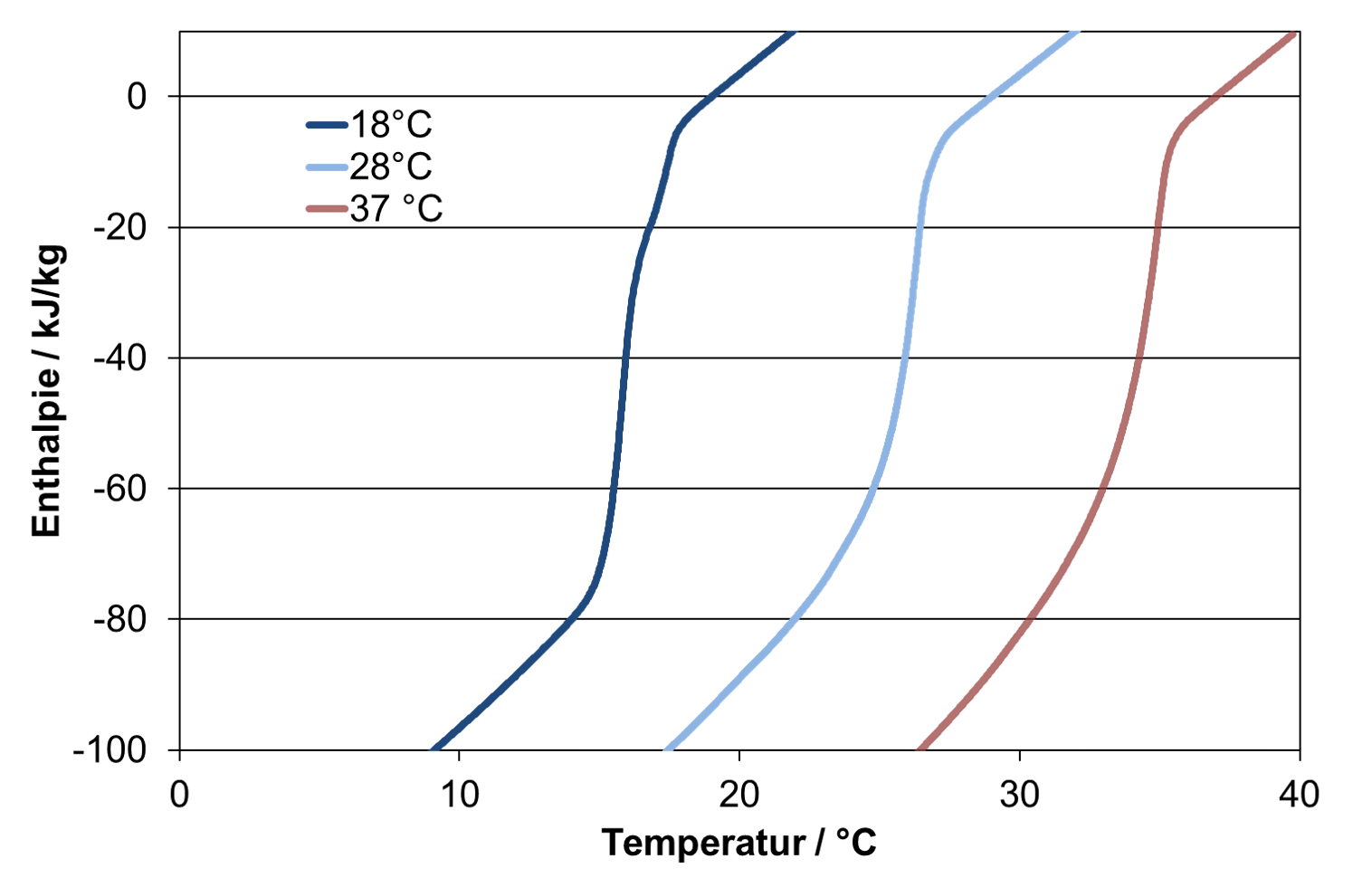

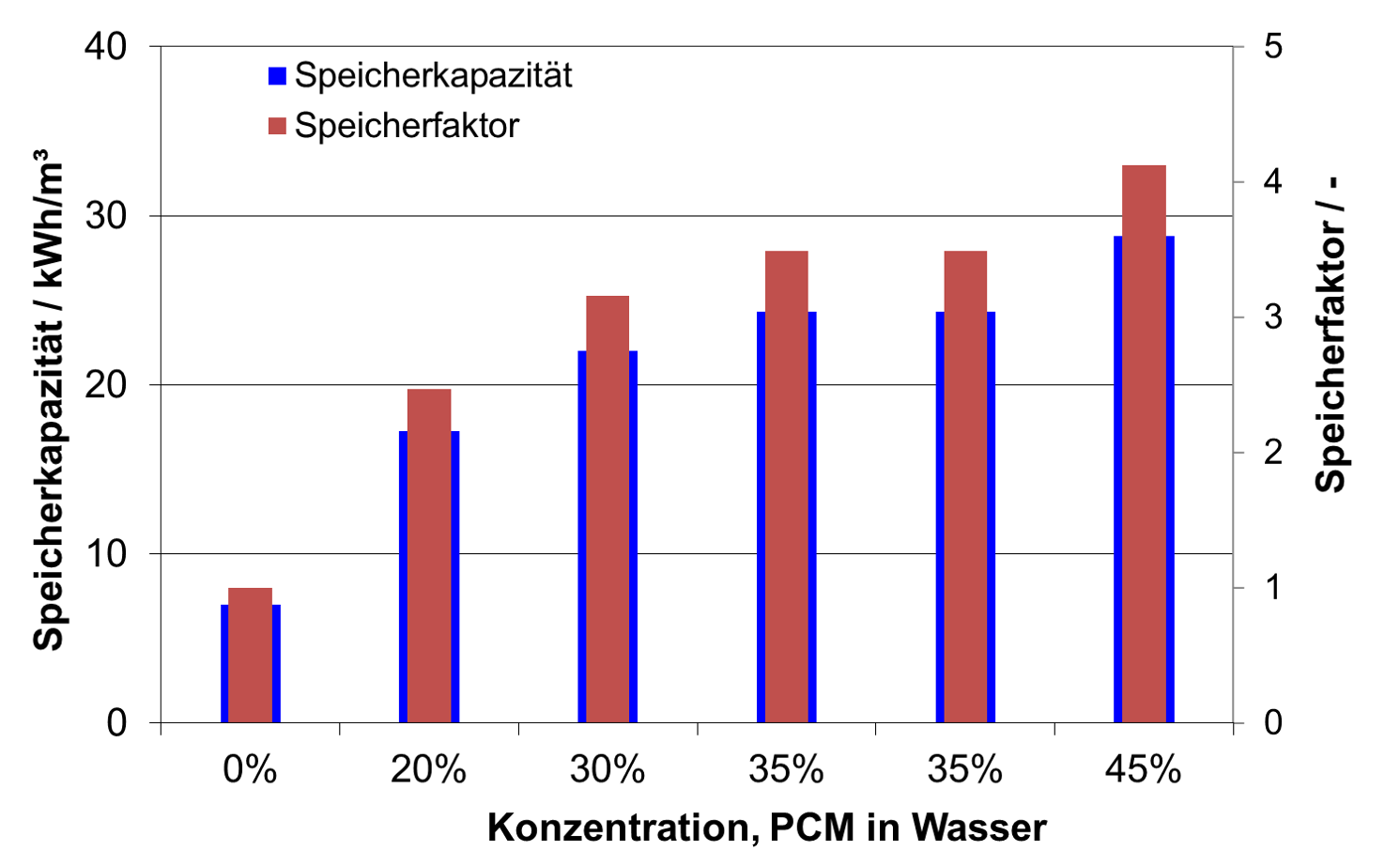

We primarily use kerosenes with application-specific melting temperatures, which are dispersed or emulsified in water. Depending on the temperature range, storage densities are achieved that are about 3 to 4 times higher than those of water.

The aim of the development is, on the one hand, to achieve high thermomechanical stability and, on the other hand, large-scale production. After successful development, the PCM emulsions will be demonstrated in the addressed applications and characterized in comparison to the standard heat transfer medium used in each case.

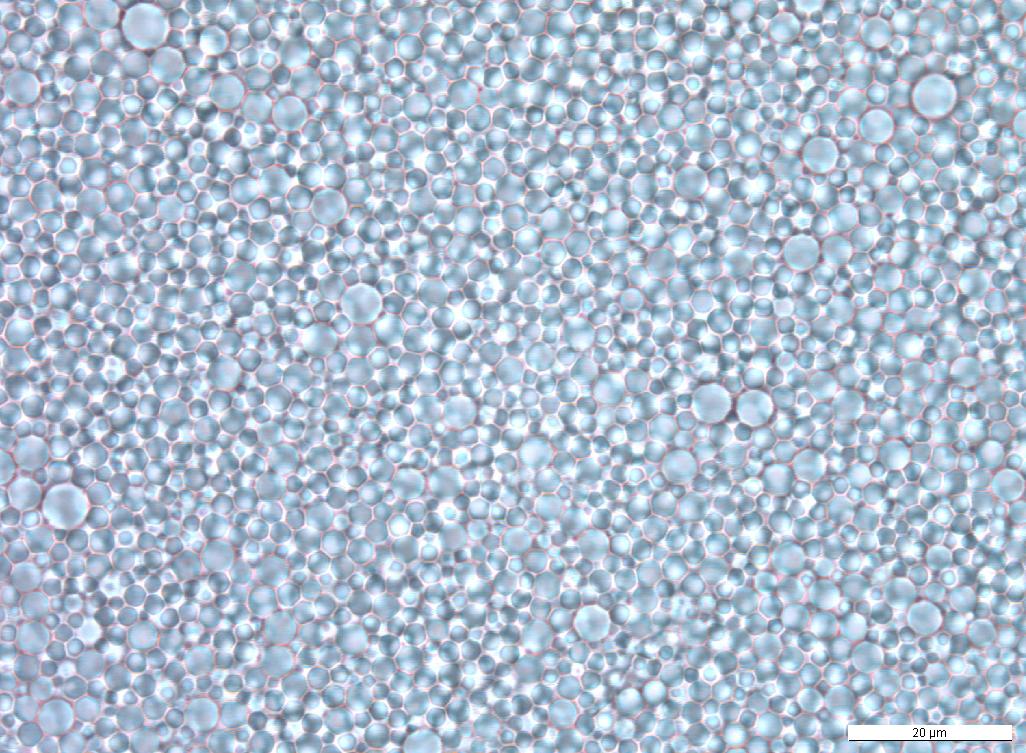

PCM emulsions are high performance heat transfer fluids and offer high heat capacities especially at low temperature spreads. They are prepared by dispersing or emulsifying an organic phase change material (PCM) in water. Surfactants stabilize the PCM droplets finely dispersed in the water. Regardless of the aggregate state of the dispersed PCM, the PCM emulsion is liquid and can be conveyed through a hydraulic network. Thus, standard plate heat exchangers can be used for heat transfer into the PCM emulsion for loading and unloading, as well as comparatively simple storage tanks for storage, which overall reduces system costs compared to other PCM storage concepts.

At Fraunhofer ISE, we primarily use kerosenes as PCM with melting temperatures between 14 °C and 70 °C. We disperse between 30 and 45 wt.% kerosene in water and achieve storage densities that are 3 to 4 times higher than water, depending on the temperature spread. This is particularly advantageous for systems that are operated within a very narrow temperature spread. Compared with storage systems that use water as heat transfer and storage medium, the volume of the storage tanks can be reduced accordingly, which offers advantages in terms of space requirements and weight, especially in mobile applications. But there are also advantages in building applications due to the reduction of storage volumes, e.g. for cold storage tanks.

In the "Optimus" project, suitable PCMs with melting temperatures between 10 and 18 °C, 20 and 28 °C as well as 45 and 55 °C are being developed for each application (buildings, industry, battery cooling and heat pumps). So far, stabilities of 10,000 thermal and mechanical cycles have been achieved. Due to the supercooling of the PCMs used, we currently achieve storage densities up to 3 times higher than with water. In further steps, the formulation will be further optimized to achieve even higher stabilities as well as lower subcooling and thus higher storage densities.

In the project, up to 20 m³ of the emulsions will be produced. For this purpose, the production of the PCM emulsions on a large scale will be realized in close cooperation with our partner H&R Wax & Specialties GmbH, in order to demonstrate them also in larger storage units, e.g. cold storage units for building air conditioning or process cooling at the end of the project.