Jahr

Year | Titel/Autor:in

Title/Author | Publikationstyp

Publication Type |

|---|

| 2025 |

Cost sharing mechanisms for carbon pricing: What drives support in the housing sector?

Kaestner, Kathrin; Sommer, Stephan; Berneiser, Jessica; Henger, Ralph; Oberst, Christian |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Technologies for Climate Neutral Districts: Agent Based Energy Management and Blockchain Based Organization for Energy Communities

Surmann, Arne; Utz, Manuel |

Aufsatz in Buch

Book Article

|

| 2024 |

Feeling the breeze? Ventilation practices and occupant requirements for mechanical ventilation in residential buildings

Berneiser, Jessica; Auerswald, Sven; Maier, Diana; Gölz, Sebastian; Carbonare, Nicolas; Pflug, Thibault |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

A Climate-Neutral Smart City District Supported by Digital Solutions

Elberzhager, Frank; Hupp, Steffen; Polst, Svenja; Stüpfert, Phil; Surmann, Arne |

Aufsatz in Buch

Book Article

|

| 2023 |

Stochastic Nonlinear Model Predictive Control for a Switched Photovoltaic Battery System

Groß, Arne; Wille-Haußmann, Bernhard; Wittwer, Christof; Achzet, Benjamin; Diehl, Moritz |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

A Voltage Sensitivity Based Equivalent for Active Distribution Networks Containing Grid Forming Converters

Ungerland, Jakob; Poshiya, Nikhilkumar; Biener, Wolfgang; Lens, Hendrik |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Evaluation of Equivalent Dynamic Active Distribution Network Models with Individual and Aggregated Consideration of Grid Forming Converters

Ungerland, Jakob; Lens, Hendrik |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Großer Wurf oder leeres Versprechen? Attraktivität und Wirtschaftlichkeit der Gemeinschaftlichen Gebäudeversorgung

Kühnbach, Matthias; Surmann, Arne; Oberfeier, Paula |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Analysing Grid-Level Effects of Photovoltaic Self-Consumption Using a Stochastic Bottom-up Model of Prosumer Systems

Karalus, Steffen; Köpfer, Benedikt; Guthke, Philipp; Killinger, Sven; Lorenz, Elke |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Wie agieren Quartiere netzverträglich? Flexibilitätspotenziale der Vor-Ort-Versorgung

Flemming, Sebastian; Bender, Tom; Surmann, Arne |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Demonstrating Clean Energy Transition Scenarios in Sector-Coupled and Renewable-Based Energy Communities

Maruf, Md Nasimul Islam; Mahmud, Shadman; Pasarín, Iván S.; Giani, Federico; Degrave, Aurélien; Guerra, Carlos Funez; Lopez, Susana; Mesonero, Ivan |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Ultrafast GaAs MOVPE growth for power electronics

Lackner, David; Urban, Theresa; Lang, Robin; Pellegrino, Carmine; Ohlmann, Jens; Dudek, Volker |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Dynamic pricing and the flexible consumer - Investigating grid and financial implications: A case study for Germany

Stute, Judith; Kühnbach, Matthias |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

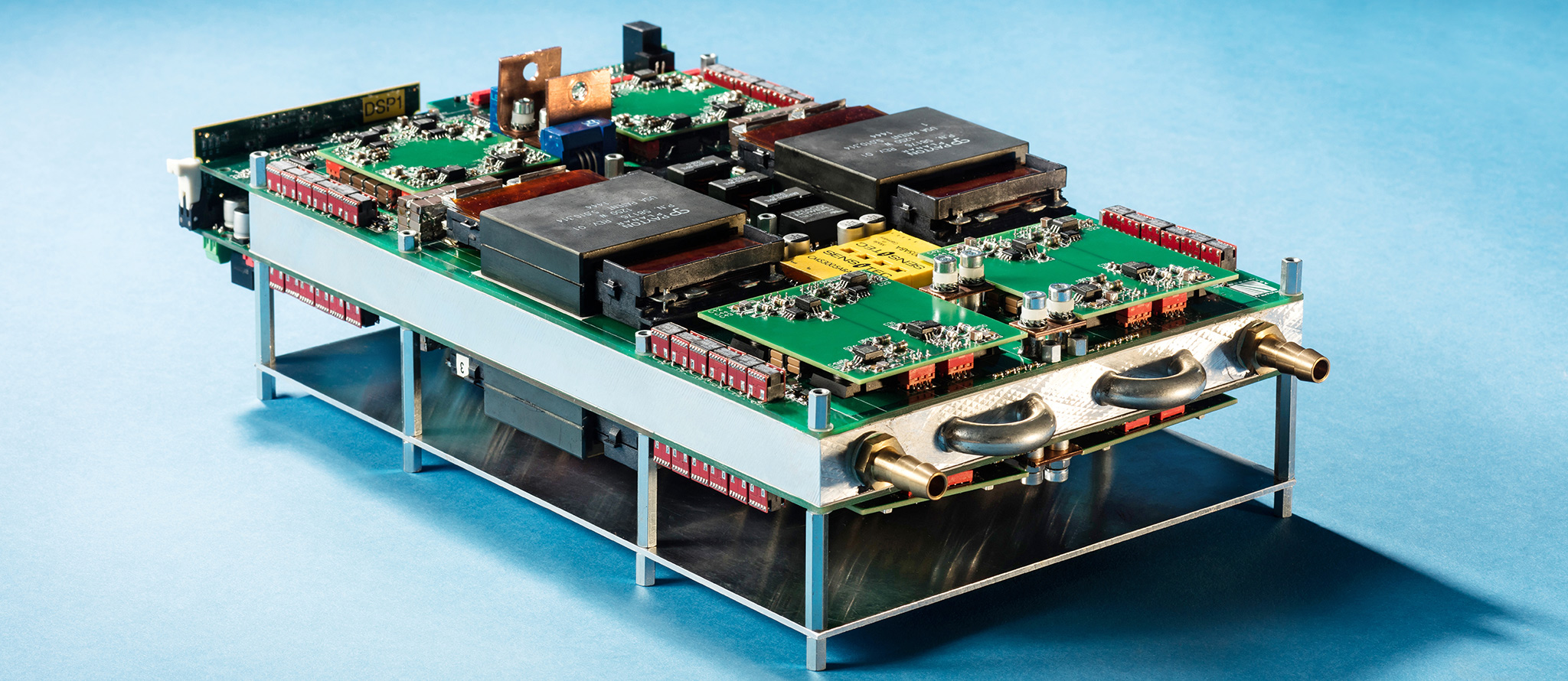

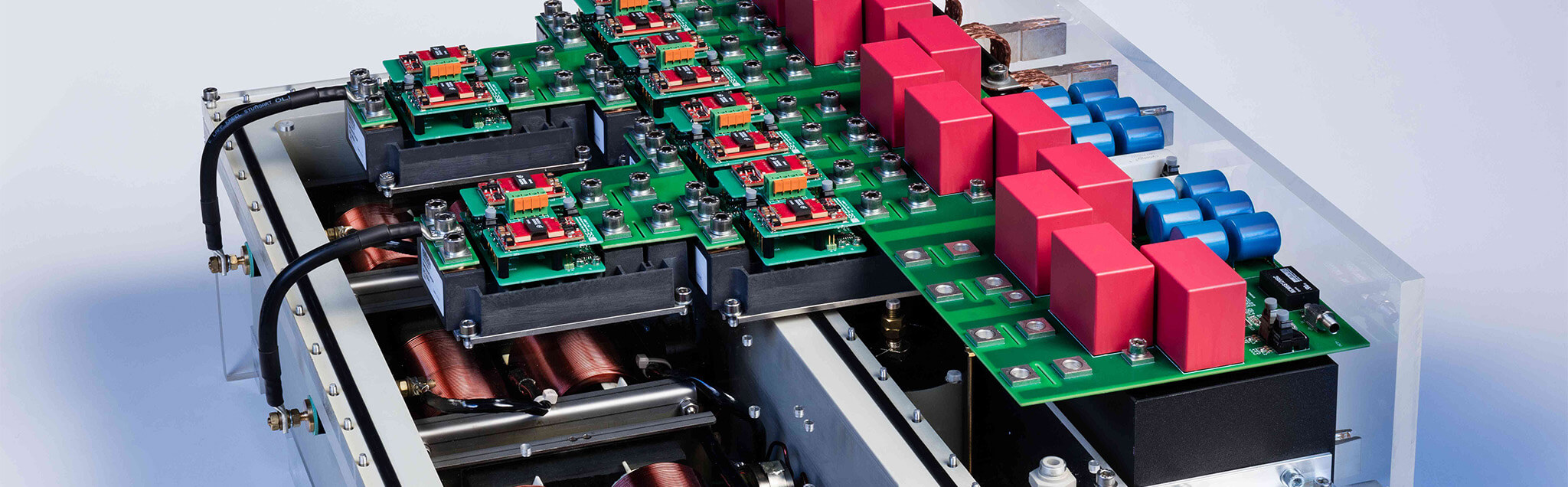

Power Module Design for GaN Transistors Enabling High Switching Speed in Multi-Kilowatt Applications

Wöhrle, Dennis; Burger, Bruno; Ambacher, Oliver |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Integrating flexibility provision into operation planning: A generic framework to assess potentials and bid prices of end-users

Wanapinit, Natapon; Thomsen, Jessica; Weidlich, Anke |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Tripling land use in West Africa

Berneiser, Jessica; Bingwa, Brendon |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Renewable Energy Communities as Modes of Collective Prosumership: A Multi-Disciplinary Assessment, Part I - Methodology

Chaudhry, Shubhra; Surmann, Arne; Kühnbach, Matthias; Pierie, Frank |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Datenblatt-Wirkungsgrad kein Entscheidungskriterium

Hensel, Andreas; Hans, Franziska Alina; Eyhorn, Steffen |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Review of Internal Carbon Pricing and the Development of a Decision Process for the Identification of Promising Internal Pricing Methods for an Organisation

Gorbach, Gregor; Kost, Christoph; Pickett, C. |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Dekarbonisierung der Industrie - Treiber, Hemmnisse und Handlungsoptionen

Riedel, Franziska Sophie; Vogel, Moritz; Berneiser, Jessica; Kucknat, Johanna |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Comparing the Energy System of a Facility with Uncertainty about Future Internal Carbon Prices and Energy Carrier Costs Using Deterministic Optimisation and Two-Stage Stochastic Programming

Gorbach, Oliver Gregor; Thomsen, Jessica |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Lohnt sich die österreichische Energiegemeinschaft auch für Deutschland? Eine Fallstudie

Surmann, Arne; Erge, Thomas; Kühnbach, Matthias; Kohrs, Robert |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Renewable Energy Communities as Modes of Collective Prosumership: A Multi-Disciplinary Assessment, Part II - Case Study

Chaudhry, Shubhra; Surmann, Arne; Kühnbach, Matthias; Pierie, Frank |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Modeling of Photovoltaic Inverter Losses for Reactive Power Provision

Grab, Robin; Hans, Franziska Alina; Rojas Flores, Mariano Ivan; Schmidt, Heribert; Rogalla, Sönke; Engel, Bernd |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Give Up Flights? Psychological Predictors of Intentions and Policy Support to Reduce Air Travel

Berneiser, Jessica; Becker, Annalena; Loy, Laura |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Beyond good faith: Why evidence-based policy is necessary to decarbonize buildings cost-effectively in Germany

Singhal, Puja; Pahle, Michael; Kalkuhl, Matthias; Levesque, Antoine; Sommer, Stephan; Berneiser, Jessica |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Find the balance: How do electricity tariffs incentivize different system services from demand response?

Wanapinit, Natapon; Thomsen, Jessica; Weidlich, Anke |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Multidimensional Criticality Assessment of Metal Requirements for Lithium-ion Batteries in Electric Vehicles and Stationary Storage Applications in Germany by 2050

Bongartz, L.; Shammugam, Shivenes; Gervais, Estelle; Schlegl, Thomas |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

An MILP Model for Evaluating the Optimal Operation and Flexibility Potential of End-Users

Wanapinit, Natapon; Thomsen, Jessica; Kost, Christoph; Weidlich, A. |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Comparison of Short-term Electrical Load Forecasting Methods for Different Building Types

Groß, Arne; Lenders, A.; Schwenker, F.; Braun, D.; Fischer, David |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Effect of the Foresight Horizon on Computation Time and Results using a Regional Energy Systems Optimization Model

Thomsen, Jessica; Saad Hussein, Noha; Dolderer, A.; Kost, Christoph |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

A Strategy to Increase the Resource Efficiency of Renewable Energy Technologies

Henning, Hans-Martin; Shammugam, Shivenes; Gervais, Estelle; Schlegl, Thomas |

Aufsatz in Buch

Book Article

|

| 2021 |

Open-source simulation of the long-term diffusion of alternative passenger cars on the basis of investment decisions of private persons

Senkpiel, Charlotte; Berneiser, Jessica; Baumann, D. |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Microgrid Systems: Towards a Technical Performance Assessment Frame

Marchand, Sophie; Monsalve, Cristian; Reimann, Thorsten; Heckmann, Wolfram; Ungerland, Jakob; Lauer, Hagen; Ruhe, Stephan; Krauß, Christoph |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Optimized Strategic Planning of Future Norwegian Low-Voltage Networks with a Genetic Algorithm Applying Empirical Electric Vehicle Charging Data

Wruk, J.; Cibis, K.; Resch, Matthias; Saele, H.; Zdrallek, M. |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Economic Evaluation of Operation Strategies for Battery Systems in Football Stadiums

Berg, Kjersti; Resch, Matthias; Weniger, Thaddäus; Simonsen, Stig |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Participative Renewable Energy Community - How Blockchain-Based Governance Enables a German Interpretation of RED II

Chantrel, S.; Surmann, Arne; Erge, Thomas; Thomsen, Jessica |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

E-Mobilität im Carsharing und in Fuhrparks

Stryi-Hipp, Gerhard; Sprengeler, Matti; Nguyen, P.; Popova, R.; Landfester, G. |

Aufsatz in Buch

Book Article

|

| 2021 |

Synergies Between Renewable Energy and Flexibility Investments: A Case of a Medium-Sized Industry

Wanapinit, Natapon; Thomsen, Jessica |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Barriers to internal carbon pricing in German companies

Riedel, F.; Gorbach, Gregor; Kost, Christoph |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Getting Prices for Prosumers Right? Incentivizing Investment and Operation of Small-scale PV-Battery Storage Systems Through Prices, Charges and Levies

Thomsen, Jessica; Weber, C. |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

A method of optimizing and spatially distributing heating systems by coupling an urban energy simulation platform and an energy system model

Steingrube, Annette; Bao, K.; Wieland, Stefan; Lalama, A.; Kabiro, P.; Coors, V.; Schröter, B. |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Modeling of Persistence, Non-acceptance and Sufficiency in Long-term Energy Scenarios for Germany

Kost, Christoph; Brandes, Julian; Senkpiel, Charlotte; Sterchele, Philip; Wrede, Daniel; Henning, Hans-Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Raw Material Needs for the Large-Scale Deployment of Photovoltaics - Effects of Innovation-Driven Roadmaps on Material constraints until 2050

Gervais, Estelle; Shammugam, Shivenes; Friedrich, Lorenz; Schlegl, Thomas |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Techno-Economic Assessment of Flexibility Options Versus Grid Expansion in Distribution Grids

Resch, Matthias; Bühler, J.; Schachler, B.; Sumper, A. |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Impact of Internal Carbon Prices on the Energy System of an Organisation's Facilities in Germany, Japan and the United Kingdom Compared to Potential External Carbon Prices

Gorbach, Gregor; Saad Hussein, Noha; Thomsen, Jessica |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

The role of norms and collective efficacy for the importance of techno-economic vehicle attributes in Germany

Berneiser, Jessica; Senkpiel, Charlotte; Steingrube, Annette; Gölz, Sebastian |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

6-W Optical Power Link with Integrated Optical Data Transmission

Helmers, Henning; Armbruster, Cornelius; Ravenstein, Moritz von; Derix, David; Schöner, Christian |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Assessment of flexible electric vehicle charging in a sector coupling energy system model - Modelling approach and case study

Sterchele, Philip; Kersten, K.; Palzer, Andreas; Hentschel, J.; Henning, Hans-Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Die Energiewende und der Einfluss Gesellschaftlicher Verhaltensweisen

Henning, Hans-Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

"Die Versorgungssicherheit ist sehr hoch"

Henning, Hans-Martin; Lehmann, K. |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Adjustment of the Life Cycle Inventory in Life Cycle Assessment for the Flexible Integration into Energy Systems Analysis

Betten, T.; Shammugam, S.; Graf, Roberta |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Systemic Evaluation of Effects of Regional Self-Supply Targets on the German Electricity System Using Consistent Scenarios and System Optimization

Senkpiel, Charlotte; Hauser, Wolfgang |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Die Rolle des Stromsystems in Transformationspfaden zur Klimaneutralität

Kost, Christoph; Brandes, Julian; Haun, Markus; Henning, Hans-Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

From residential electric load profiles to flexibility profiles

Fischer, David; Surmann, Arne; Biener, Wolfgang; Selinger-Lutz, Oliver |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Towards 3D-Lithium Ion Microbatteries Based on Silicon/Graphite Blend Anodes Using a Dispenser Printing technique

Drews, Mathias; Tepner, Sebastian; Haberzettl, P.; Gentischer, Harald; Beichel, W.; Breitwieser, Matthias; Vierrath, Severin; Biro, Daniel |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Stochastic model predictive control of photovoltaic battery systems using a probabilistic forecast model

Groß, Arne; Wittwer, Christof; Diehl, Moritz |

Zeitschriftenaufsatz

Journal Article

|

| 2019 |

Die Energiewende erfolgreich steuern

Henning, Hans-Martin; Pittel, K. |

Zeitschriftenaufsatz

Journal Article

|

| 2019 |

Modeling Investment Decisions in Renewable Energy Technologies: An Introduction to Simulating Technology Diffusion

Senkpiel, Charlotte; Berneiser, Jessica; Steingrube, Annette; Biener, Wolfgang; Gölz, Sebastian |

Zeitschriftenaufsatz

Journal Article

|

| 2019 |

Applications of SiC Devices

Kranzer, Dirk; Hensel, Andreas; Thoma, Jürgen; Armbruster, Cornelius; Hercegfi, Patrick; Schönberger, Stefan |

Aufsatz in Buch

Book Article

|

| 2019 |

An analytical approach for estimating the global horizontal from the global tilted irradiance

Halilovic, S.; Bright, Jamie M.; Herzberg, Wiebke; Killinger, Sven |

Zeitschriftenaufsatz

Journal Article

|

| 2019 |

Electric Vehicles' Impacts on Residential Electric Local Profiles - A Stochastic Modelling Approach Considering Socio-Economic, Behavioural and Spatial Factors

Fischer, David; Harbrecht, A.; Surmann, Arne; McKenna, Russell |

Zeitschriftenaufsatz

Journal Article

|

| 2019 |

Bayesian parameterisation of a regional photovoltaic model - Application to forecasting

Saint-Drenan, Y.-M.; Vogt, S.; Killinger, S.; Bright, J.M.; Fritz, R.; Potthast, R. |

Zeitschriftenaufsatz

Journal Article

|

| 2019 |

Data Article: Distributed PV Power Data for Three Cities in Australia

Bright, Jamie M.; Killinger, Sven; Engerer, N. |

Zeitschriftenaufsatz

Journal Article

|

| 2019 |

Coal phase out, energy efficiency, and electricity imports: Key elements to realize the energy transformation

Kost, Christoph; Palzer, Andreas; Sterchele, Philip; Stephanos, Cyril; Hartmann, Niklas; Henning, Hans-Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2019 |

Ist die Energiewende noch zu retten?

Henning, Hans-Martin; Umbach, E. |

Zeitschriftenaufsatz

Journal Article

|

| 2018 |

Real live demonstration of MPC for a power-to-gas plant

Fischer, David; Kaufmann, F.; Hollinger, Raphael; Voglstätter, Christopher |

Zeitschriftenaufsatz

Journal Article

|

| 2018 |

Power-to-gas in a smart city context - influence of network restrictions and possible solutions using on-site storage and model predictive controls

Fischer, David; Kaufmann, F.; Selinger-Lutz, Oliver; Voglstätter, Christopher |

Zeitschriftenaufsatz

Journal Article

|

| 2018 |

Flexibility assessment of a pool of residential micro combined heat and power systems

Selinger-Lutz, Oliver; Pratidino, G.; Hollinger, Raphael; Fischer, David; Koch, B.; Wittwer, Christof |

Zeitschriftenaufsatz

Journal Article

|

| 2018 |

PV-Lichtbögen sicher erkennen

Eger, F. |

Zeitschriftenaufsatz

Journal Article

|

| 2018 |

Sektorenkopplung und Systemintegration. The Next Big Thing für die Energiewende

Rosenfeld, Georg; Henning, Hans-Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2015 |

Towards a Better Understanding of Harmonics and Power Electronics

Rogalla, Sönke; Ackermann, Florian; Bihler, Nicolas; Dötter, Gregor; Singer, Roland; Wolf, E. |

Zeitschriftenaufsatz

Journal Article

|