Jahr

Year | Titel/Autor:in

Title/Author | Publikationstyp

Publication Type |

|---|

| 2025 |

Charge Extraction Multilayers Enable Positive-Intrinsic-Negative Perovskite Solar Cells with Carbon Electrodes

Lukas, Tino; Seo, Seongrok; Holzhey, Philippe; Stewart, Katherine; Henderson, Charlie; Wagner, Lukas; Beynon, David; Watson, Trystan; Kim, Ji-Seon; Kohlstädt, Markus; Snaith, Henry |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Optimizing aesthetic appearance of perovskite solar cells using color filters

Schaible, Jonas; Winarto, Hanifah; Škorjanc, Viktor; Yoo, Danbi; Zimmermann, Lea; Jäger, Klaus; Sekulic, Ivan; Schneider, Philipp-Immanuel; Burger, Sven; Wessels, Andreas; Bläsi, Benedikt; Becker, Christiane |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

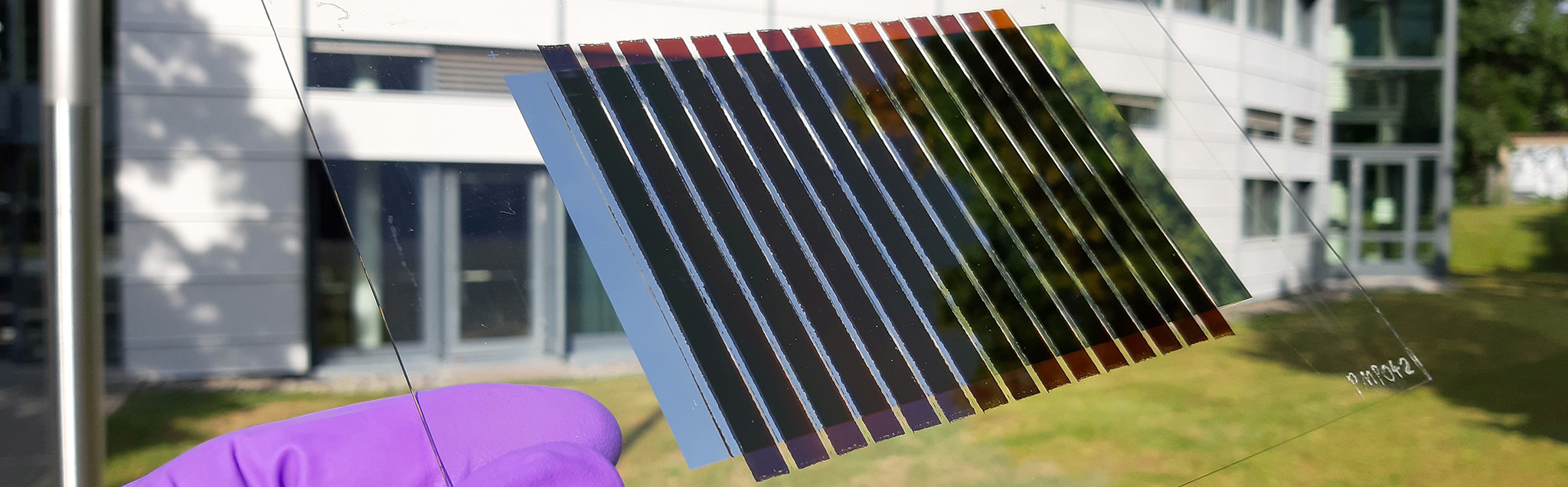

Suppressing halide segregation in wide-bandgap perovskite absorbers by transamination of formamidinium

Loukeris, Georgios; Baretzky, Clemens; Bogachuk, Dmitry; Gillen, Audrey Elizabeth; Yang, Bowen; Suo, Jiajia; Kaiser, Waldemar; Mosconi, Edoardo; De Angelis, Filippo; Boschloo, Gerrit; Bett, Andreas W.; Würfel, Uli; Kohlstädt, Markus |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Towards More Reliable Measurement Procedures of Perovskite-Silicon Tandem Solar Cells: The Role of Transient Device Effects and Measurement Conditions

Meßmer, Christoph Alexander; Chojniak, David; Bett, Alexander J.; Reichmuth, Kasimir; Hohl-Ebinger, Jochen; Bivour, Martin; Hermle, Martin; Schön, Jonas; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

Minimizing Recombination at the Perovskite/C60 Interface through a Volatile Highly Dense Molecular Interlayer

Ye, Fangyuan; Zhang, Shuo; Lang, Felix; Raoufi, Meysam; Liang, Jianjun; Levine, Igal; Hempel, Hannes; Menzel, Dorothee; Zu, Fengshuo; Albrecht, Steve; Korte, Lars; Meßmer, Christoph Alexander; Schön, Jonas; Glunz, Stefan; Unold, Thomas; Koch, Norbert; Neher, Dieter; Ye, Dongting; Wu, Yongzhen; Stolterfoht, Martin |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

PhocoHila - Photonische Prozesse zum schnellen, präzisen und flexiblen Heizen von Halbleiterbauelementen

Meyer, Fabian; Münzer, Anna; Folcarelli, Lukas; Roder, Sebastian; Schubert, Martin |

Bericht

Report

|

| 2025 |

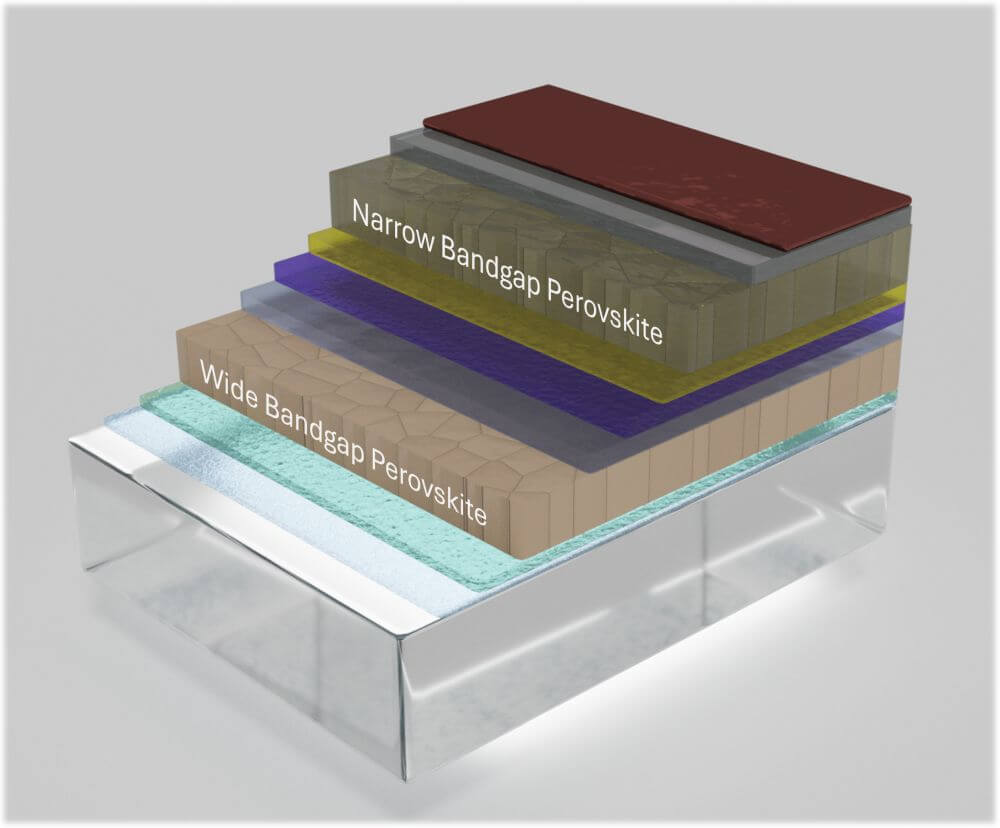

Photostable Inorganic Perovskite Absorber via Thermal Evaporation for Monolithic Perovskite/Perovskite/Silicon Triple-Junction Solar Cells

Gupta, Yashika; Heydarian, Minasadat; Heydarian, Maryamsadat; Er-Raji, Oussama; Günthel, Michael; Fischer, Oliver; Baretzky, Clemens; Schulze, Patricia; Bivour, Martin; Wolf, Stefaan de; Glunz, Stefan; Borchert, Anna Juliane |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Loss Analysis of a Perovskite/Perovskite/Silicon Solar Cell

Restat, Luis; Meßmer, Christoph Alexander; Schön, Jonas; Heydarian, Maryamsadat; Heydarian, Minasadat; Schubert, Martin; Glunz, Stefan |

Poster

|

| 2024 |

Opto-electrical modelling of perovskite/perovskite/silicon triple-junction solar cells: Towards the practical efficiency potential

Restat, Luis; Meßmer, Christoph Alexander; Heydarian, Maryamsadat; Heydarian, Minasadat; Schön, Jonas; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Understanding Ion-Related Performance Losses in Perovskite-Based Solar Cells by Capacitance-Voltage Measurements and Simulation

Meßmer, Christoph Alexander; Parion, Jonathan; Meza, Cristian V.; Ramesh, Santhosh; Bivour, Martin; Radhakrishnan, Hariharsudan S.; Schön, Jonas; Schubert, Martin; Glunz, Stefan; Heydarian, Maryamsadat |

Vortrag

Presentation

|

| 2024 |

Impact of perovskite subcell breakdown on the performance of perovskite/perovskite/silicon triple-junction solar cells

Heydarian, Maryamsadat; Bett, Alexander J.; Meßmer, Christoph Alexander; Aulich, Johanna; Fischer, Oliver; Heydarian, Minasadat; Gupta, Yashika; Schulze, Patricia; Borchert, Anna Juliane; Schindler, Florian; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Future Photovoltaic Technology

Bett, Andreas W. |

Vortrag

Presentation

|

| 2024 |

Progress and Challenges in Tandems

Hermle, Martin |

Vortrag

Presentation

|

| 2024 |

Transition of the Energy System and the Impact of Photovoltaics

Bett, Andreas W. |

Vortrag

Presentation

|

| 2024 |

Enabling Silver-Free Metallization of the Rear Side of iTOPCon Cells Through Laser Bonding of Thin Aluminum Foil

John, Oliver; Ourinson, Daniel; Emanuel, Gernot; Brand, Andreas; Nekarda, Jan; Preu, Ralf |

Vortrag

Presentation

|

| 2024 |

Passivating Inorganic Interlayers at the Perovskite/C60 Interface in Monolithic Perovskite Silicon Tandem Solar Cells

Modes, Johanna; Schulze, Patricia; Hartwig, Carl Eric; Lange, Stefan; Richter, Armin; Borchert, Anna Juliane; Bett, Andreas W. |

Vortrag

Presentation

|

| 2024 |

Quick Spectrometric Characterization of Monolithic Perovskite Silicon Tandem Solar Cells Using Monochromatic Light Sources

Fischer, Oliver; Bett, Alexander J.; Abrorov, Khusan; Mahmoud, Mohamed Abdelaziz Abdelnaby; Schindler, Florian; Glunz, Stefan W.; Schubert, Martin C. |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

The resource demands of multi-terawatt-scale perovskite tandem photovoltaics

Wagner, Lukas; Suo, Jiajia; Yang, Bowen; Bogachuk, Dmitry; Gervais, Estelle; Pietzcker, Robert; Gassmann, Andrea; Goldschmidt, Jan Christoph |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Understanding Ion-Related Performance Losses in Perovskite-Based Solar Cells by Capacitance Measurements and Simulation

Meßmer, Christoph Alexander; Parion, Jonathan; Meza, Cristian V.; Ramesh, Santhosh; Bivour, Martin; Heydarian, Minasadat; Schön, Jonas; Radhakrishnan, Hariharsudan S.; Schubert, Martin; Glunz, Stefan |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Passivation and Charge Carrier Selectivity Optimization for Narrow Bandgap Perovskite Solar Cells

Vicha, Athanasia; Loukeris, Georgios; Kohlstädt, Markus; Würfel, Uli; Bett, Andreas W. |

Vortrag

Presentation

|