| Duration: | December 2013 - December 2017 |

| Contracting Authority/ Sponsors: | Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU) |

| Project Partners: | Brandenburg Technical University, DBI-Gastechnologisches Institut GmbH Freiberg, German Environmental Aid, German Aerospace Center |

| Projektfokus: |

WESpe – Technical and Economic System Analysis for Power-to-gas Systems

The systemic relevancy and advantages of power-to-gas for an energy system in Germany mainly supplied from renewable energies are generally known to the public and in the research community. They have been proven by several studies of different stakeholders. The expert discussion focuses now on business models and specific technical implementations, based on which power-to-gas can be of major importance in the energy system today and in the next 20 years. In the “WESpe” project, scientists of the involved research institutes address the important aspects for power-to-gas, such as public acceptance, location assessment, evaluation of core components and storage units, as well as the technical and economic system analysis using simulation models.

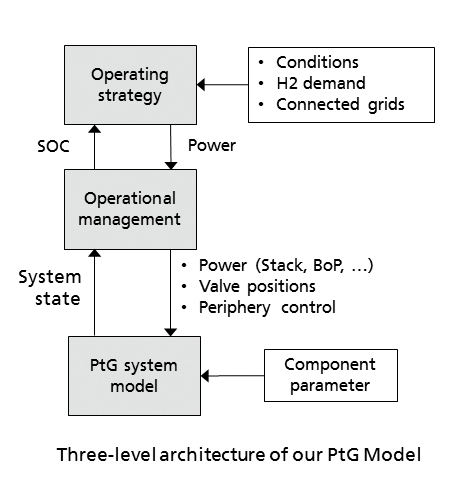

For the project objective of a “technical and economic system analysis of power-to-gas systems, Fraunhofer ISE uses a dynamic system model that has been developed at Fraunhofer ISE since the beginning of 2013. Due to its modular structure, the division in different model levels (physical level, operational management, and dispatching) and its continuously growing model library, this model is very well suited for the analysis of system architectures, operating strategies, business models and profit forecasts.

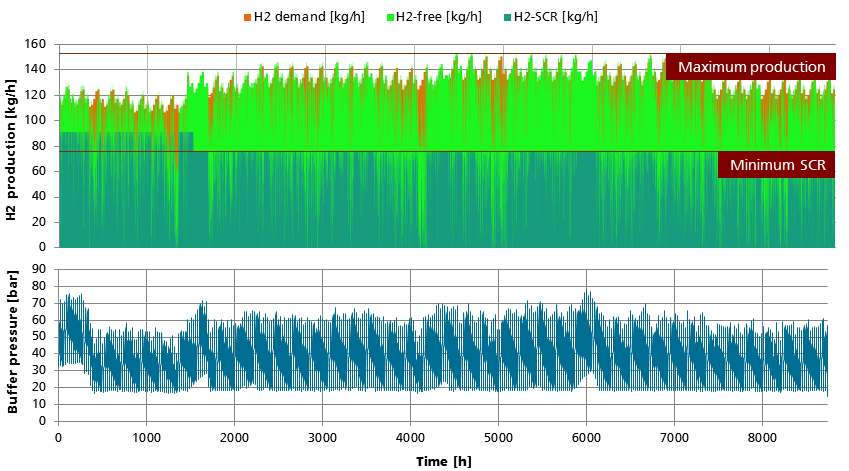

For system analysis, business model-specific power-to-gas system architectures are designed from the core components electrolyzer, gas cleaning, compressor, storage unit, refrigeration system, and gas consumer, and reproduced in the model. The power supply requirements (e.g., system service, use of excess power or power purchase at the power exchange) and the requirements of the gas side (e.g., delivery commitments, maximum feed quantities) are mapped using dispatching strategies. Component limitations (e.g., maximum load reversal ramps, minimum partial load, start times, thermal limits) are considered by the operational management algorithm. In the field of tension of these requirements and limitations, operational management and dispatching are tested and further developed in the model framework to achieve an optimum and obtain understanding regarding the critical boundary conditions of the plant.

Using the results of the model-based system analysis, power-to-gas business models, resulting operational management strategies and plants can be assessed technically. A database can be created for the further economic investigation.