| Laufzeit: | April 2014 - August 2016 |

| Kooperationspartner: | CEA-LETI (Grenoble), INES (Chambéry) |

| Projektfokus: |

Virtual Lab CEA – Fraunhofer ISE for Ultra High Efficiency Photovoltaics

Extremely thin cells on metal foil with recyclable substrates

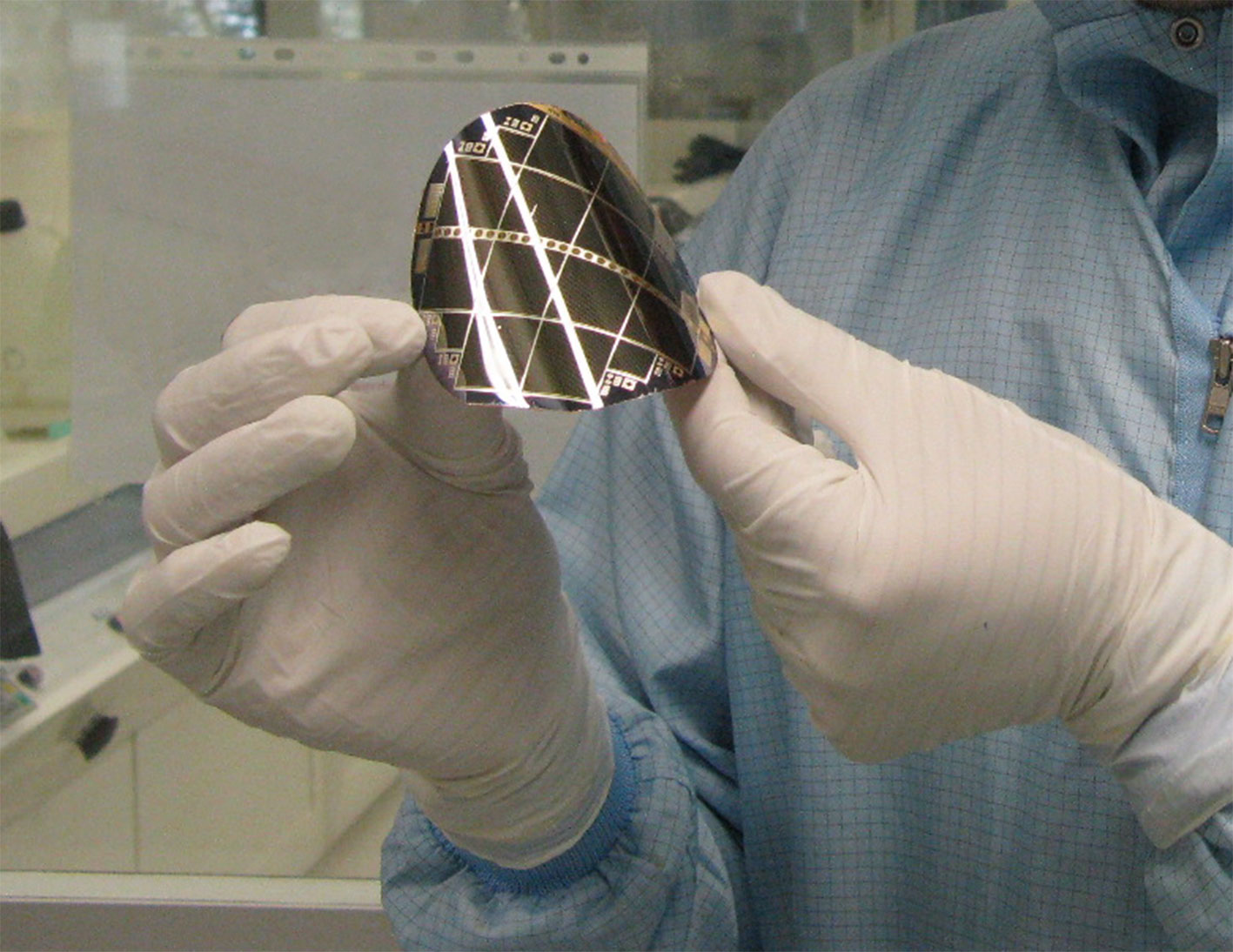

The costs of high-efficiency III-V multi-junction solar cells can be reduced when the valuable GaAs substrates are recycled and re-used for the growth of additional solar cells. Therefore we are developing a method, where the ultra-thin solar cell is separated from its substrate by selective etching. The cell is mechanically stabilized by a thin metal layer. These flexible cells can be used for cost-efficient low-concentration PV systems for example. Our development is done in cooperation with our research partners at CEA-Leti and INES.

Multi-junction solar cells achieve the highest efficiencies for converting sunlight into electrical energy with currently up to 46 %. The III-V semiconductor substrates used for epitaxial growth are a cost factor, although they do not contribute to the actual function of the solar cell. For this reason, it is economically reasonable to separate the solar cell (which has a thickness of several microns only) from its substrate and to reuse the substrate.

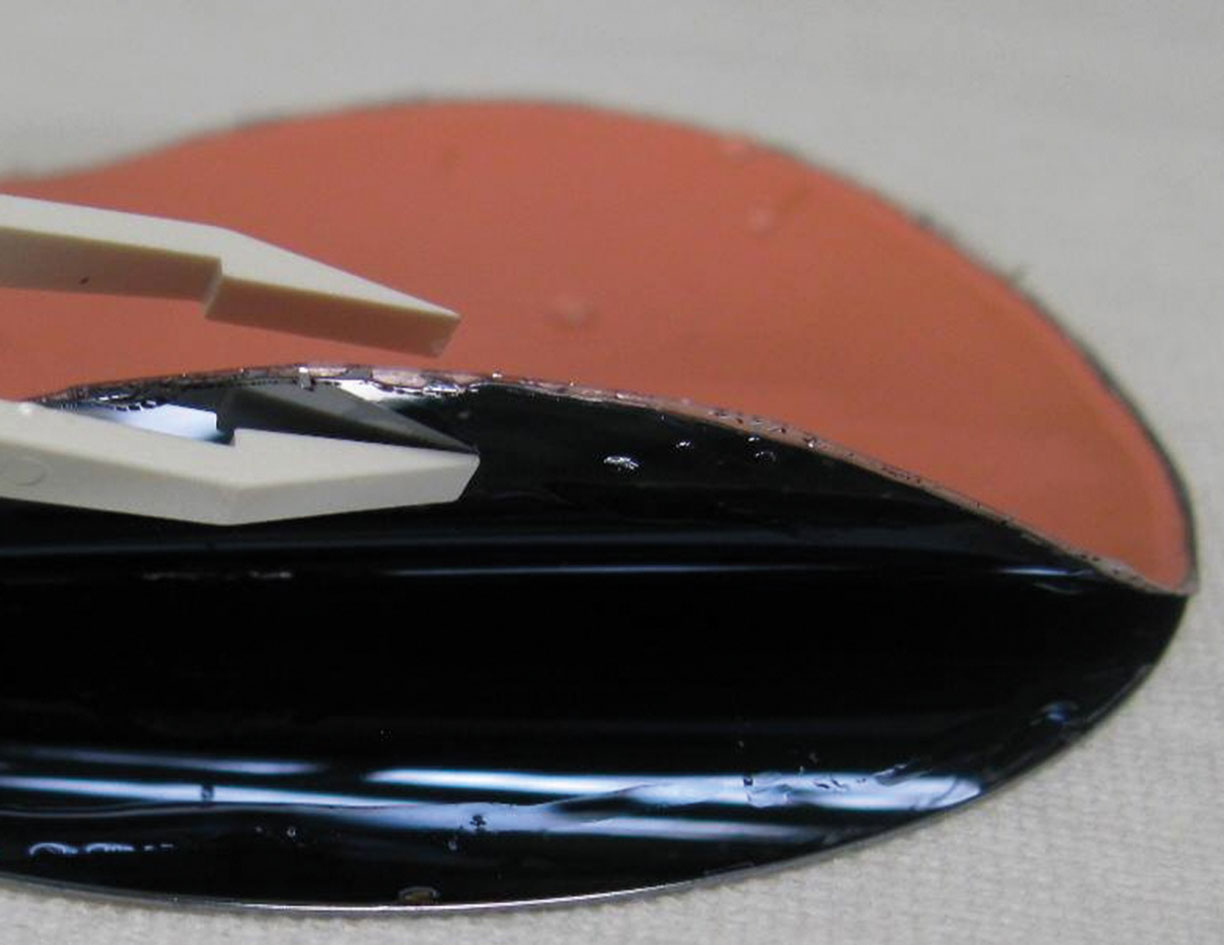

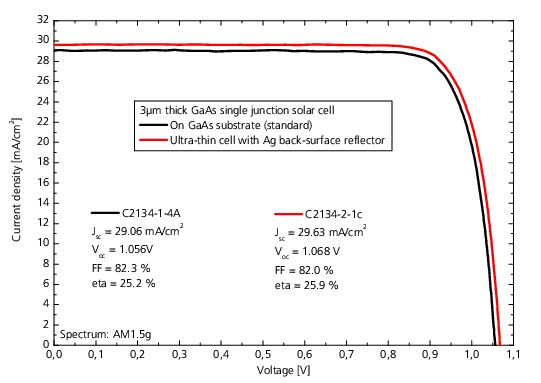

For this purpose, we have developed a process, where a so-called sacrificial layer is grown between solar cell and substrate, which can be selectively etched in a wet-chemical process. This separates the very thin solar cell and the substrate. To stabilize the solar cell, a thin metal layer is deposited first. The result after substrate detachment is a flexible and very lightweight solar cell. The metal layer also helps in separating the solar cell and the substrate as it causes minor rolling of the solar cell. Thus, the etching process can be executed without mechanical aids. The growth substrate can then be reused for solar cell growth without expensive processing.

Using this process, multi-junction solar cells with an efficiency of 27.5 % under the AM1.5d spectrum were manufactured. These solar cells as well as tandem solar cells can, e.g., be cost-effectively used in low-concentrating photovoltaics systems and have already reached a degree of efficiency of 28.4 % for a concentration of 15 suns.