| Duration: | October 2012 - September 2014 |

| Contracting Authority/ Sponsors: | German Federal Ministry of Economics and Technology (BMWi) |

| Project Partners: | G.tecz Engineering UG, Betonfertigteile Spürgin GmbH & Co. KG, Visiotex GmbH, Zehnder GmbH, Karlsruhe Institute for Technology (KIT) |

| Website: | www.tabsolar.de |

TABSOLAR – Thermally Activated Building Systems of Ultra-High Performance Concrete

Within the ”TABSOLAR“ research project, Fraunhofer ISE is developing novel building components with integrated fluid channels on the basis of ultra-high performance concrete (UHPC). Multi-functional components such as building-integrated solar collectors or thermally activated building systems (TA BS) for new buildings and building renovation are to be implemented with innovative production methods. We have already successfully deposited a spectrally selective coating onto the first UHPC samples. Further, our thermal simulations have demonstrated that high thermal efficiency can be expected with UHPC if components are suitably dimensioned.

In the ”TABSOLAR“ joint research project, we are cooperating with five project partners to develop multi-functional, lowtemperature building components such as walls, ceilings or floors, which fulfil structural (e.g. load-bearing wall), thermally activated (fluid-conducting), thermally passive (thermal insulation) and design (structure, colour, coating) functions. The basis for the novel concept is ultra-high performance concrete (UHPC), which can be formed into very finely structured, material-saving and yet also extremely strong building components.

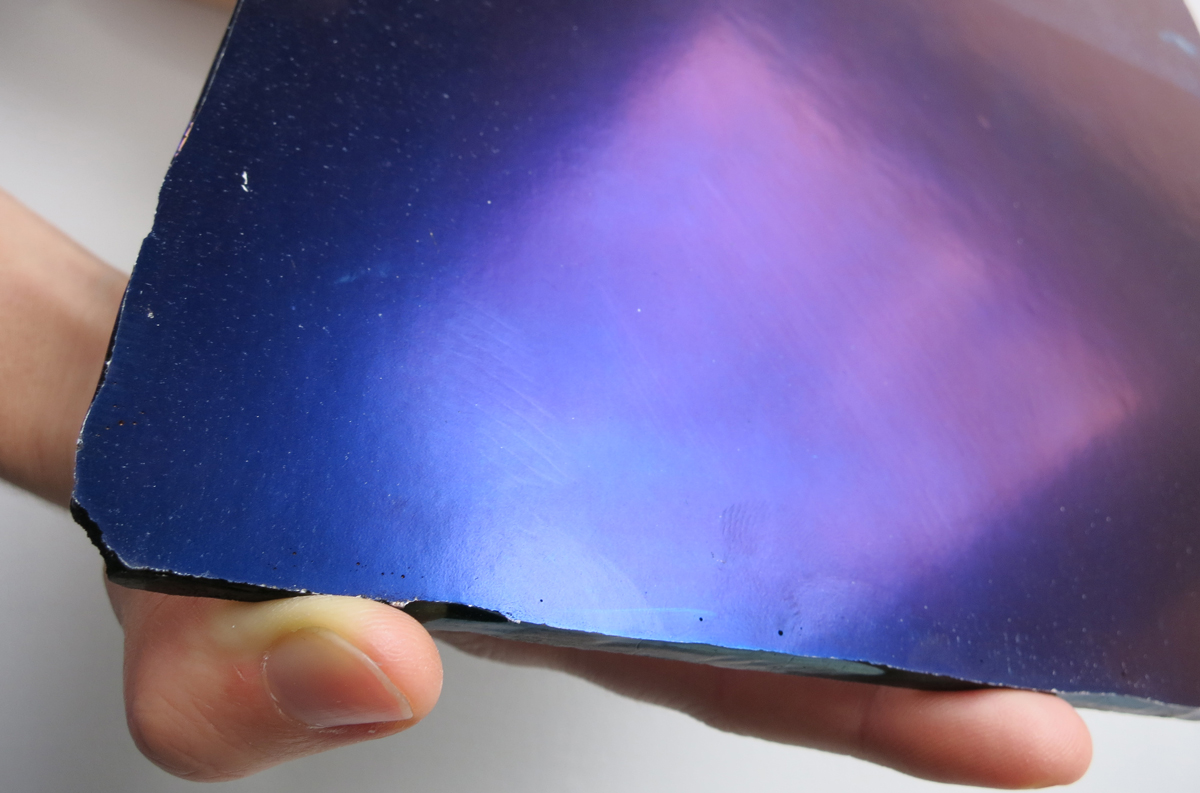

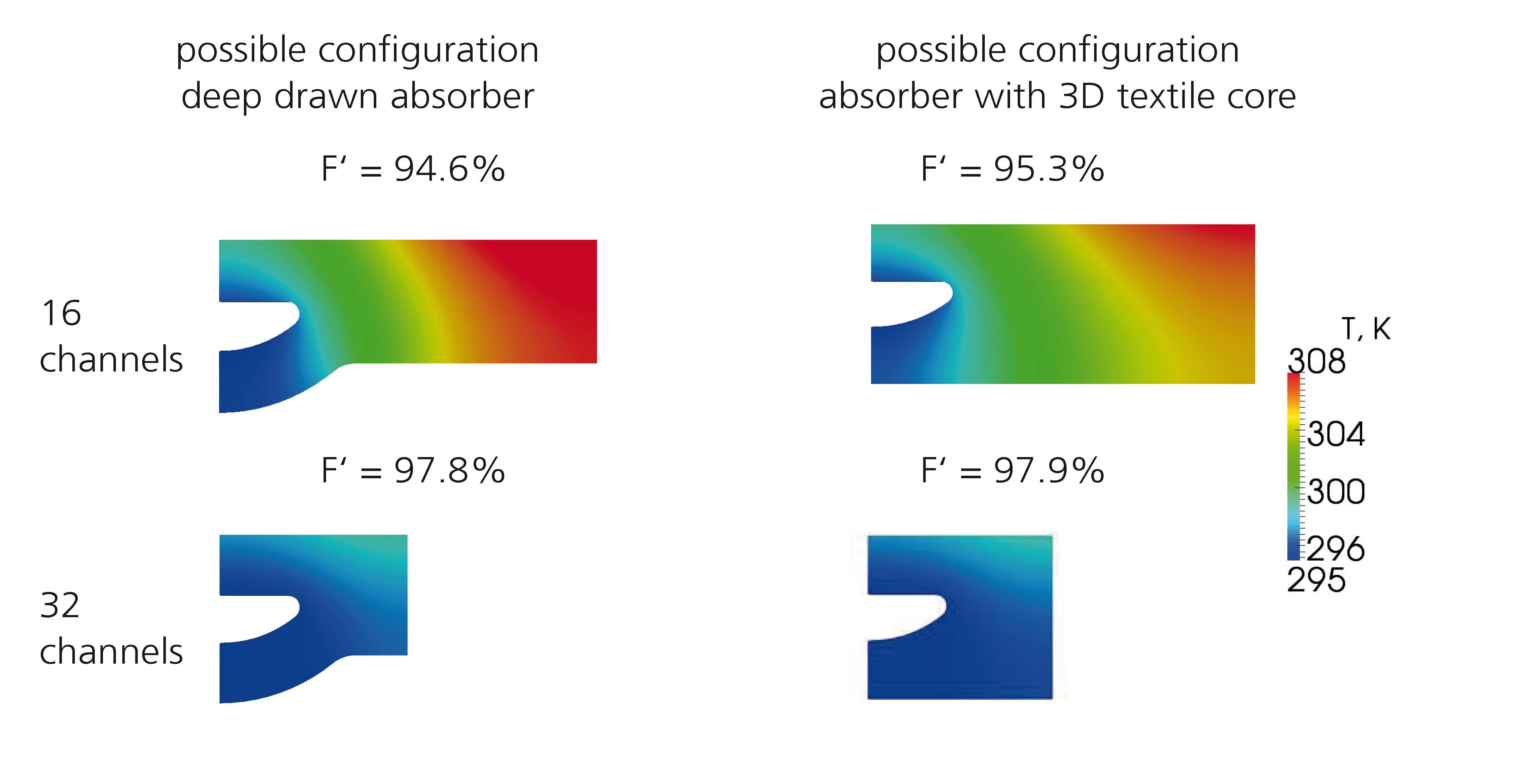

Two possible new production technologies are being investigated in parallel as part of the project: a vacuum deepdrawing process which we have developed and patented, and casting around a core of knitted, three-dimensional channels. The channel structures are designed with the help of our FracTherm® procedure. We have successfully deposited spectrally selective coatings onto the first UHPC samples (Fig. 1). In comparison to metals, the thermal conductivity of UHPC is low; we have measured it to be 1.9 W/(mK) at 20 °C and 1.6 W/(mK) at 100 °C. We have thus prepared thermal models and carried out numerical simulations to determine the collector efficiency factor F’, which is a measure for the thermal efficiency of a solar absorber (Fig. 2). The determined values are in the same range as for typical, state-of-the-art metal solar absorbers or better.